12 Automatic Lathe Manufacturers in china in 2024

Precision Automatic Lathe

Top 12 Automatic Lathes manufacturer in China in 2024, Expert Insights for Your In-depth Understanding.

When your factory urgently needs to purchase a batch of advanced automatic lathes for producing small parts, you may find yourself searching on Google for a long time without clear direction. As a company lacking experience in purchasing automatic lathes, you may feel confused and anxious. No need to worry – I have specifically compiled a list of well-regarded CNC automatic lathe manufacturing companies in the Chinese market from the perspective of users and with a professional outlook. In this article, we delve into the top 12 CNC automatic lathes in China, providing expert insights to enhance your understanding of these lathes.

This list not only allows you to quickly find the automatic lathes you need but also, from the perspective of professional users, ensures that you can select the most suitable equipment for your machining factory. By choosing these manufacturing companies, you will not only obtain high-quality automatic lathes but also enjoy the support and services of professional teams. This will inject new vitality into your company, adding more convenience and efficiency to the production process.

Whether you are looking to increase production capacity or seeking higher precision solutions, these recommended companies can meet your needs. On the journey of procuring automatic lathes, let these recommendations guide you, taking your company to new heights. Let’s work together to contribute to your company’s success and create a better future.

What is the automatic lathe?

What is the Principle of Automatic Lathes?

What kinds of parts could be used by automatic lathe?

List of 12 Automatic Lathe Manufacturers in China in 2024.

The First Level

Company Name: ZHANGJJAGANG MINGYANG PRECISION MACHINERY MANUFACTURING CO..LTD

Company Overview:

The company’s products are suitable for cutting non-ferrous materials such as copper, aluminum, synthetic resin, stainless steel, and are widely used in the precision parts processing and production of industries such as automotive, electronics, clocks, optoelectronics, bathroom fixtures, appliances, and textiles. Particularly in the production of precision electrical components, hardware small parts, electronic components, computer accessories, pen tips, and other precision parts, they exhibit characteristics of high precision, efficiency, long service life, and low cost.

With a history of over 30 years, the company is a professional automatic lathe manufacturer. Upholding the principle of “Quality First, Service Supreme,” the company currently ranks first in terms of market share and production and sales volume in the Mingyang automatic lathe markets in the Yangtze River Delta and Pearl River Delta regions, earning recognition from major customers.

Zhangjiagang Mingyang Precision Machinery Manufacturing Co., Ltd. is a modern enterprise with Taiwanese investment, focusing on design, development, manufacturing, sales, and after-sales service. With decades of innovative spirit, the company develops and produces high-precision lathes. All lathes are certified by ISO9001 and CE, enjoying good sales and reputation globally. The company has two major production bases, occupying a significant share of the global CNC lathe market and is committed to advancing CNC lathe technology. With nearly 40 years of development, the company has over 30 professional technical personnel.

Adhering to the quality policy of “meticulous design, strict production control, scientific management, and integrity service,” the company provides high-quality products to society and its vast customer base.

History:

Website: Read more

TW headquarters website: Read More

Automatic Lathe Model: M-1525-1/M-2025-1 Usage Evaluation: Top in sales, performs very well. Shortcomings: High volume of lathe orders, long lead times. Suitable for processing products: Products with diameters ranging from Φ8 to Φ12.

Automatic lathe machine price:

8300usd-14300usd

The Second Level

Company Name: SHYE TOWEN MACHINERY CO., LTD.

Company Overview:

Widely used in the mass production of various precision components for industries such as automotive, electronics, optical instruments, computers, clocks, sanitary ware, and hardware accessories, these automatic lathes achieve automation, enhance maximum output, and ensure high quality. Due to improvements in structural design, they can operate for extended periods, offering convenience and economic practicality even for small-batch, diverse production.

SHYE TOWEN Automatic Lathe Factory in Taiwan has sub-brands including SH (SAN HO), SL (San-Li), and XB (XIE BO).

Website:Read more

now could not open the website

Automatic Lathe Model:XB-2025 XB-1525 STM-2025 STM-1525 STM-3225

Usage Evaluation: Second in sales, good reputation.

Strengths: Excellent for riveting, fast threading speed, suitable for small components with a diameter of Φ6mm.

Weaknesses: Unstable performance when handling larger components in the Φ12mm-Φ20mm size range.

Automatic lathe machine price:

8300usd-14300usd

Company Name:SAN HO DETAILED MACHINERY CO., LTD.

Company Overview:

On March 19, 2007, the company began in-house manufacturing of automatic lathes, ensuring the prevention of counterfeit OEM factories producing SAN HO automatic lathe brands. SAN HO Precision Machinery Co., Ltd. specializes in the fields of machine tool and mold manufacturing agency. With a forward-looking perspective and skilled, meticulous service enthusiasm, the company has gained praise from numerous customers.

In an environment where online connectivity is increasingly developed, SAN HO lathes always keep pace, aspiring to transform customer relationships into a fast, convenient, and user-friendly network. We advocate for excellent quality and prioritize customer satisfaction. Recently, we have reinforced professional technology and customer service informatization, aiming to enhance our adaptive capabilities and maintain long-term partner relationships with customers based on cooperation and trust, fostering mutual growth.

In the industry and related sectors, SAN HO lathes consistently exhibit a considerable degree of core value and competitiveness.

Website:Read more

Automatic Lathe Model:SH-1525/SH-1525A ,SH-2025/SH-2025A

Usage Evaluation: Similar quality to SHYE TOWEN, which is SHYE TOWEN sub-brand. Parts are not compatible with other automatic lathes, and the spindle size differs from that of other automatic lathes.

Automatic lathe machine price: About 7900usd

The Third Level

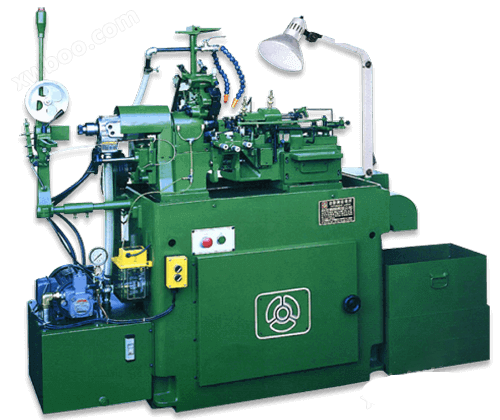

Company Name:GE FONG MACHINERY CO., LTD

Company Overview:

GE FONG MACHINERY CO., LTD employs the “QC Engineering Chart” as an inspection standard in the machining process. This chart facilitates various monitoring and controls throughout the manufacturing process, ensuring that all outputs at each stage are under control. It further guarantees the high quality and stability of the machinery. In terms of service, the company adheres to the principle of “Customer First,” providing the highest level of enthusiastic service to achieve customer satisfaction and aiming for sustainable operations.

With abundant experience in machinery manufacturing, GE FONG MACHINERY CO., LTD’s machines are marketed globally. Over the years, the company has continuously engaged in research and development, enhancing the performance and quality of existing machines, developing new models, and collaborating with domestic academic institutions to incorporate advanced technologies. The company consistently adopts various international quality certifications, obtaining CE standard certification in May 1996 and AMTRI CE certification for CNC lathes. In January 2001, it achieved ISO9000 (2000 version) quality certification.

GE FONG MACHINERY CO., LTD produces a diverse range of machines, including high-tech, high-precision, high-accuracy CNC computer lathes and cost-effective traditional cam-type automatic lathes. The company aims to meet customers’ multifunctional and comprehensive service needs in machine usage. It believes that its machines greatly contribute to enhancing productivity in various industries and significantly reduce manufacturing production costs. The company looks forward to collaboration and support from all sectors to create a better future together.

History:

GE FONG has extensive experience and a larger global market share, making it an early producer of cam-operated and sliding-head CNC lathes compared to its Taiwanese competitors. Continuously improving machine quality and performance, GE FONG collaborates with domestic academic institutions to ensure advanced technology. GE FONG products have obtained CE and ISO9000 certifications. The product range includes high-tech, high-precision, high-performance automatic lathes for customers to choose from.

We firmly believe that our products are highly beneficial for customers in improving productivity and reducing production costs.

Website:Read More

Automatic Lathe Model:G-1515A G-1525A G-2025A,G-3225HA

G-4225HA

Usage Evaluation: Tailstock pads(dovetail gasket) are prone to breakage, and small components are susceptible to issues.

Automatic lathe machine price:About 8600USD

Company Name: Dongguan Wangzhu Machinery Trading Co., Ltd.

Company Overview:

Throughout the years, we have consistently pursued innovative development, elevated technological capabilities, expanded equipment, and provided customers with the most refined professional processing. Adhering to a “technology-oriented” philosophy, we aim to enhance process technology, producing high-precision products. With a competitive advantage in precision technology, we have gained recognition and support in markets such as the Americas, Europe, and Southeast Asia.

The company is committed to continuous growth and improvement, respecting professionalism, prioritizing quality, and upholding a service-first principle. We strive to present you with the best products, highest quality, and the most reasonable prices, along with the fastest service.

History:

GE FONG has extensive experience and a larger global market share, making it an early producer of cam-operated and sliding-head CNC lathes compared to its Taiwanese competitors. Continuously improving machine quality and performance, GE FONG collaborates with domestic academic institutions to ensure advanced technology. GE FONG products have obtained CE and ISO9000 certifications. The product range includes high-tech, high-precision, high-performance automatic lathes for customers to choose from.

We firmly believe that our products are highly beneficial for customers in improving productivity and reducing production costs.

Website:Read More

Automatic Lathe Model:W-1568/W-2068

Usage Evaluation: Suitable for small components with a diameter of Φ6mm.

Shortcomings: Small chip evacuation groove, oil tank is not easy to clean out debris.

Automatic lathe machine price:about 8500usd

Company Name:CHIAH CHYUN MACHINERY CO., LTD.,

Company Overview:

Company Overview: CHIAH CHYUN MACHINERY CO., LTD., registered and established in Taiwan in 1988, has a history of 36 years to date. The company operates in the distribution and wholesale of CNC lathes, automatic lathes, and tabletop lathes. With a staff of 101-200 employees, the registered capital is 10 million RMB. Over the years, CHIAH CHYUN MACHINERY CO., LTD. has dedicated efforts to continuously develop higher-performance and more advanced machines.

In 2014, CHIAH CHYUN MACHINERY CO., LTD. expanded its operations by establishing another factory to meet the growing demand for production capacity. Presently, as CHIAH CHYUN MACHINERY CO., LTD., the company owns two factory buildings with a total construction area of 10,600 m2.

Website:Read More

Automatic Lathe Model:STM-1525 STM-2025

Usage Evaluation: Suitable for large components with diameters ranging from Φ12mm to Φ20mm.

Shortcomings: The slag material disposal opening is too small, prone to slag material blockage, and difficult to clean up.

Automatic lathe machine price:8200usd

Company Name: YOW CHANG TECHNOLOGY CO., LTD

Company Overview:

Dongguan YOW CHANG TECHNOLOGY CO., LTD. was established in 2009 with a registered capital of 5 million RMB. It is located in the emerging industrial city of Dalingshan Town, Dongguan City, Guangdong Province, within the Jinxiongda Industrial Zone. The company’s business scope includes the production and sale of automatic lathes, CNC lathes, automatic lathe accessories, automatic feeding machines, and hardware products. Adhering to the philosophy of “people-oriented, quality first,” the company has, in just two years, evolved into a group company integrating production and sales, with products distributed nationwide and two major sales bases established in Jiangsu and Guangdong.

History:

Website:

Automatic Lathe Model: Z-1525A/B Z-2025A/B Z-2525A/B

Usage Evaluation: Suitable for small-tooth processing, with some minor problems in the quality of accessories.

Automatic lathe machine price: About 8200 USD.

Company Name:JARNG YEONG ENTERPRISE CO., LTD.

Company Overview:

In 2011, in an effort to break away from the traditional industrial image, JARNG YEONG established the GREENWAY brand, taking a fresh and vibrant approach. The main product line includes Swiss-type CNC lathes, gang-type economic CNC lathes, turret-type CNC lathes, CNC lathes with gantry loaders or other material handling devices, and cam automatic lathes.

History:

Over time, with continuous improvement in processing technology, the company laid a solid foundation for manufacturing lathes in the future. In the pursuit of enhancing the quality of tool slide plates and parts processing, JARNG YEONG began manufacturing high-quality lathes for parts production. In 1989, JARNG YEONG ENTERPRISE CO., LTD. was established, focusing on the production of cam automatic lathes, and successfully developed CNC numerical control lathes in 1995.

With a significant improvement in the quality of processed parts and the stability of produced lathes, the company transformed into a specialized manufacturer of lathes. In addition to building a good reputation in Taiwan, it also sells its products in more than 30 countries worldwide.

Website:Read more

Automatic Lathe Model:JY-1525/2025

Usage Evaluation: Performs well, but small components are prone to issues in quality.

Automatic lathe machine price:About 8400USD

Company Name:Dongguan Taiyang Precision Machinery Co., Ltd

Company Overview:

Originating from Taiwan, the mainland factory is located in the economically developed Huade Road, Yayao Industrial Zone, Humen Town, Dongguan City, Guangdong Province. The company boasts a beautiful environment, convenient transportation, and excellent equipment, receiving widespread acclaim from various sectors of society since establishing its mainland factory.

Main Products:

Precision automatic lathes (A-1525, A-2025, A-2225), high-precision CNC lathes (CK-6136, CK-6146, CK-6146D), high-precision CNC upgraded versions (CK-3, CK-4, CK-45B, CK-45C), high-precision CNC vertical machining centers (VL-650, VL-850), high-precision CNC drilling and tapping centers (TV-500, TV-600), and short bar automatic feeding processing lathes. The precision hardware processing machinery and peripheral accessory equipment cover various specifications. This series of precision machinery finds extensive applications in hardware, electronics, electrical appliances, clocks, instruments, pen tips, eyeglasses, lighting, bathroom fixtures, automotive, optoelectronics, fishing equipment, locks, probes, connectors, plugs, mobile phone accessories, computer bolts, screws, and various screw processing fields.

Website:Read More

Automatic Lathe Model:A-1525、A-2025、A-2225

Usage Evaluation: Performs well, but small components are prone to issues in quality.

Automatic lathe machine price:About 8300USD

Company Name:Guangdong Taike Intelligent Equipment Co., Ltd.

Company Overview:

Since its establishment in 2002, the company has introduced advanced foreign technology and management systems, focusing on the research and innovation of precision machinery and the enhancement of product quality. It is committed to providing high-performance precision equipment and quality professional technical services for precision metal processing enterprises. The company has obtained 46 invention patents and utility model patents, including “CNC automatic lathe.” It has been honored with titles such as “Demonstration Unit of China Credit Enterprise Certification System,””Guangdong Province Private Science and Technology Enterprise,””High-tech Enterprise,” and “Guangdong Province Contract-abiding and Credit-respecting Enterprise.” The company has also achieved ISO9001 quality system certification, ISO14001 environmental system certification, and ISO45001 occupational health system certification.

With a first-class research base, a dedicated research and development team, advanced modern processing and tooling equipment, strong technical capabilities, and comprehensive testing methods, Guangdong Taiko Intelligent Equipment Co., Ltd. is a large high-tech joint venture (group) company. The company covers a total area of nearly 60,000 square meters, with a building area of over 30,000 square meters, an annual turnover of nearly 300 million RMB, and exports generating over 20 million RMB. It is a key enterprise in the production of high-tech precision machinery in Guangdong Province and one of the world’s largest R&D and production bases for automatic lathes.

Adhering to the development tenet of “people-oriented, innovation and progress, commitment to high-end, and quality first,” Guangdong Taiko Intelligent Equipment Co., Ltd. upholds the business philosophy of “creating a company that satisfies employees, impresses customers, and is respected by society.” The company is dedicated to building a modern precision CNC machinery with independent intellectual property rights that is “high-speed, precise, intelligent, and environmentally friendly.”

The company has established marketing agencies in more than 80 major cities in China and has set up import and export companies in Shanghai and Shenzhen. Its products are mainly sold to developed cities in mainland China and multiple countries in Asia, Europe, and America. The company has received unanimous praise from over 3,000 major customers at home and abroad.

Website:Read more

Automatic Lathe Model:A-1525A-2025A-2525

Usage Evaluation: Performs well, but small components are prone to issues in quality.

Automatic lathe machine price:About 8000USD

Company Name: Desaige Seiko Machinery Co., Ltd

Company Overview:

Currently, our core products include optical automatic edging machines, dual-spindle CNC lathe series, turning-milling compound CNC lathe series, and high-speed high-efficiency cam-type automatic lathes. These products find wide applications in industries such as optics, aerospace, automotive accessories, electronics, medical, shipbuilding, molds, hardware, and more. All workpieces are formed in a single operation, achieving product automation to enhance the manufacturing industry’s maximum output and optimal quality. We welcome individuals from all walks of life to visit our company or contact us for inquiries.

Website:Read More

Automatic Lathe Model:D-1525,D-2025

Usage Evaluation: Performs well, but small components are prone to issues in quality.

Automatic lathe machine price:7200-8600usd

Company Name: Guangdong Tairong Precision Machinery Manufacturing Co., Ltd.

Company Overview:

Our product range includes a variety of metalworking automation machine tools, such as lathes, milling machines, drills, taps, thread rolling machines, grinding machines, boring machines, spin pressing machines, polishing machines, and deburring machines. We specialize in the production of high-precision machine tools, including cam automatic lathes (converting knife-walking and heart-walking machines to CNC, simultaneously processing with multiple knives, saving labor and easy operation) and CNC lathes (vertical and horizontal knife-walking, heart-walking, whole machine and light machine, with over 30 varieties).

Additionally, we manufacture various machine tool feeders and material receivers (7-8 types), thread rolling machines (7-8 types), flat milling machines (5-8 types), small horizontal mills, precision tabletop lathes (5-8 types), lathe grinding machines, CNC centerless grinders (5-8 types), CNC vertical grinders (for lathes), CNC thread internal and external grinders, machining centers (5-8 types), engraving machines, universal internal and external grinders, CNC turning, milling, rolling, and grinding composite machines, CNC polishing machines, automated quality inspection and screening machines, self-loading and unloading gantry robots and six-axis robots, automatic chip removal machines, iron chip compaction machines, conveyors, various precision core machine tools and accessories (produced in Taiwanese factories), machine spindles, tool turrets (hydraulic, servo, power), simple power heads, and the transformation of various machine tool automation loading and unloading projects.

The company offers free technical assistance, development and design, matching solutions, training, and turnkey projects for machine tool automation loading and unloading. We specialize in customizing non-standard secondary processing machine tool automation loading and unloading dedicated machines and production lines, aiming to create the industry’s leading brand in the metalworking machine tool support industry. Our goal is to provide comprehensive solutions for the entire factory, offering one-stop services and creating globally efficient, advanced, and intelligent automation machine tools with new processes, new technologies, and new products.

Website:Read More(no website)

Automatic Lathe Model:1525,2020,2025.

Usage Evaluation: Performs well, but small components are prone to issues in quality.

Automatic lathe machine price:8400usd

Free Sample

Explore Other Guide and Resource

Swiss Machining 101: Purpose, Process, Applications and More

Wondering about Swiss Machining? Unveil every single fact on concept, process, tools, materials, applications, and more. Let’s dive in!

CNC Turning

Dive into the world of CNC turning with our comprehensive guide, exploring the meaning, types, and processes involved. Uncover the versatility of CNC lathes and their applications in automotive, agriculture,

Screw Machine Products, Processes, and Industry Leaders

Explore comprehensive Swiss Machine Products guide covering tools, techniques, and top manufacturers. Master the art of precision manufacturing for optimal results.