CNC Milling and Turning Services

CNC Milling and Turning Services

CNC Milling and Turning Services –China CNC Turning Milling Parts Manufacturer.

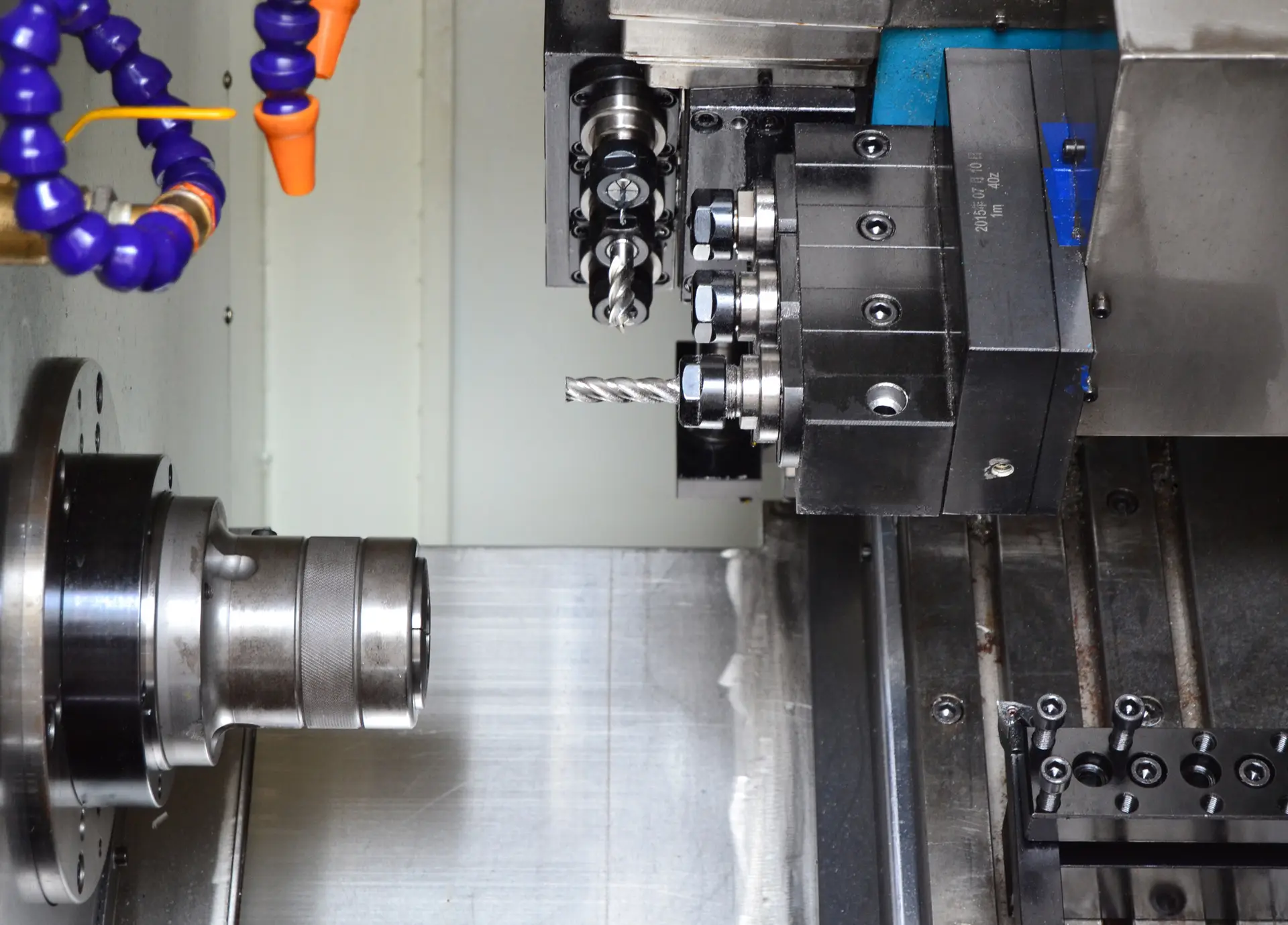

CNC milling and turning is one of the advanced manufacturing technologies in the international mechanical processing industry. It integrates turning, milling, drilling, boring, and tapping functions on a single machine tool. This technology enables the combined machining of end faces, side surfaces, milling, drilling, boring, and threading. It is particularly suitable for the machining of complex-shaped, high-precision rotational parts. With the ability to complete all or most of the processes in a single setup, it ensures precision, improves efficiency, and reduces costs. The CNC milling and turning center combines the capabilities of a CNC lathe and a CNC machining center.

CNC Milling and Turning Services

Are you in search of a suitable manufacturer for CNC turning milling parts? Masion can meet your requirements for CNC turning milling parts. We specialize in customizing various CNC turning milling parts for medical, aerospace, automotive, electronics, telecommunications, refrigeration, optics, home appliances, and robotics. We have advanced 4 axis CNC turning milling machine and a team of skilled designers, engineers, and mechanics who can address technical issues related to your complex products. Our CAD team will provide machining solutions and optimizations based on your drawings, aiming to improve product quality and reduce unit costs.

What We Do

CNC Milling and Turning materials

Steel, alloy steel, aluminum alloy, titanium alloy, magnesium alloy, zinc alloy, stainless steel, brass, bronze alloy, copper alloy, hard alloy, carbon steel, tungsten steel, plastic parts, etc.

Surface treatment capabilities

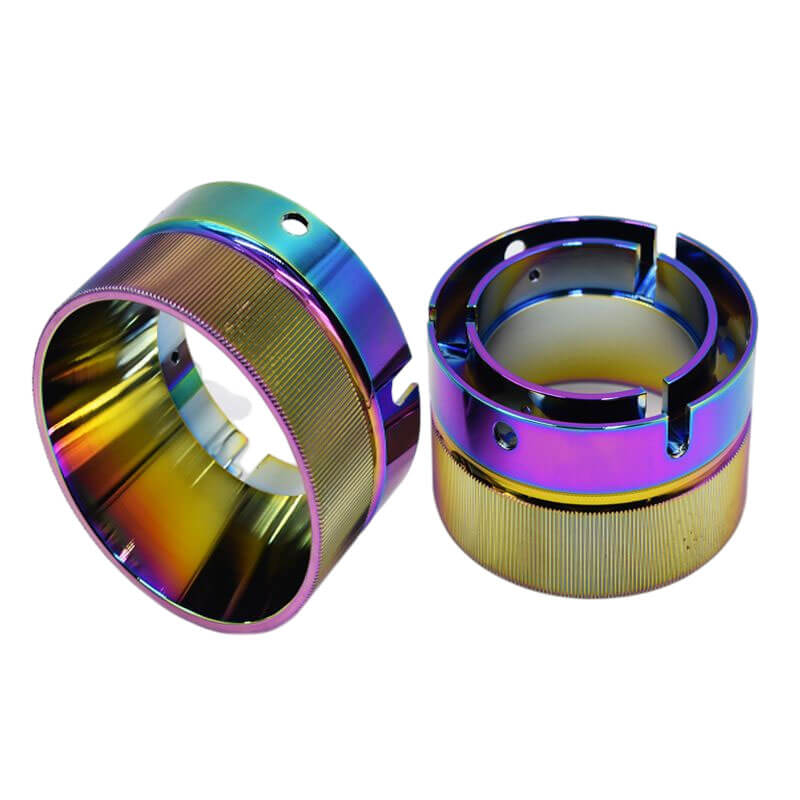

Spray painting, baking painting, plastic spraying, sandblasting, shot blasting, anodizing, hard oxidation, micro-arc oxidation, electroplating, electrophoresis, laser engraving, screen printing, wire drawing, mirror polishing, dyeing, blackening, CD pattern, etching, high gloss, corrosion pattern, glue dropping, chromate, PVD plating, laser engraving.

One-stop processing

Combined with various processes such as casting, extrusion profiles, casting, hot forging, etc., to save a significant amount of costs.

Products Gallery

CNC Milling and Turning various types of shaft

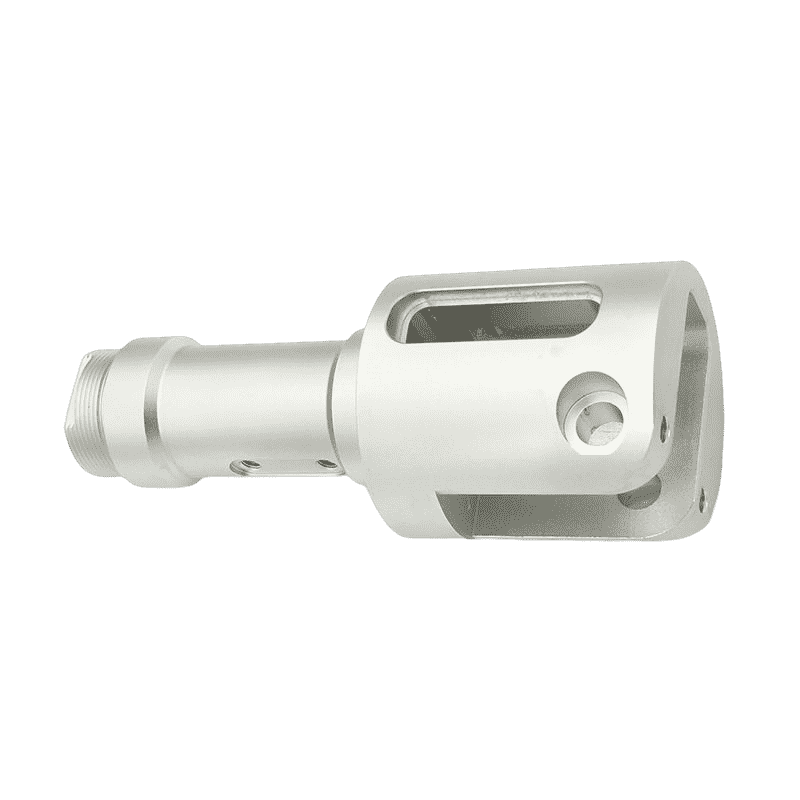

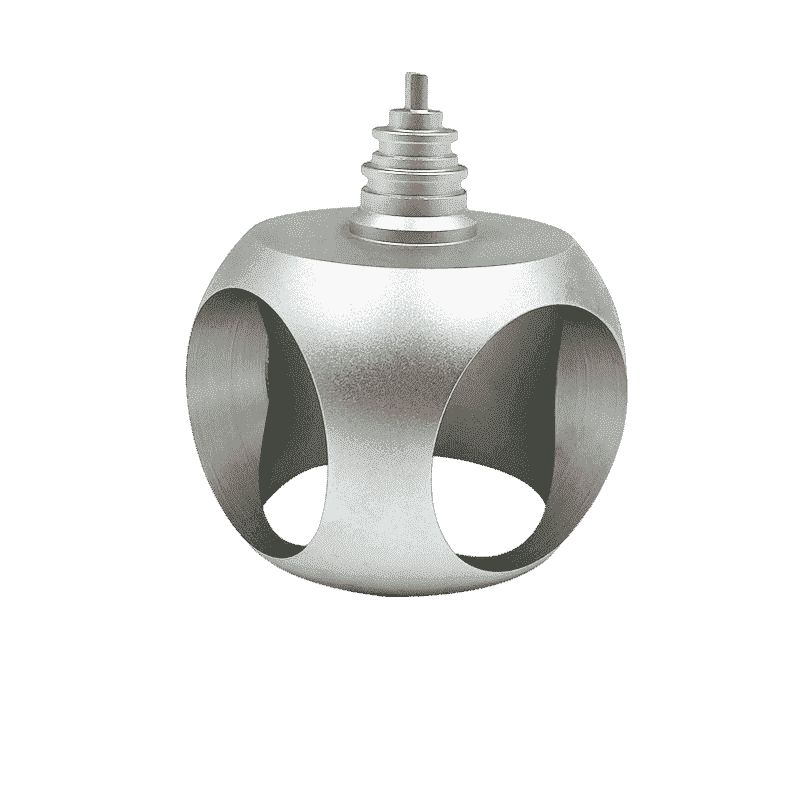

CNC Milling and Turning other parts

Swiss CNC machining automotive parts

CNC Milling and Turning Medical Equipment Parts

CNC Milling and Turning Automotive Parts

CNC Milling and Turning Robot Parts

Why Choose Masion

Rich Experience

Currently,Masion has 10 advanced CNC milling and turning machines and 15 years of experience in CNC milling and turning partsmachining such as medical, different shafts, automotive parts, robot parts, etc.

Excellent Quality Service

Masion timely communicate with customers regarding production progress, 3+1 service (three regular services plus one extra), on -time delivery, after sales service and customer satisfaction as the standard for assessing product quality.

Quality Control

Our dedicated inspection team, equipped with high-precision instruments like CMM, projector, and scanner, ensures product yield, on-time delivery, and quality assurance. 100% of the products full inspection before shipment, ensuring high-quality standards.

Precision Machining

At Masion, our CNC milling and turning processes are highly accurate, achieving ±0.002mm(0.0000787inch), ensuring our machined parts meet stringent requirements with a surface roughness of Sa < 0.05um.

Technical Strength

Masion adheres to Taiwan’s CNC turning mature experience, following a strict precision manufacturing process. Our CNC machining parts meet the highest standards of accuracy, reliability, and performance to satisfy diverse customer needs.

Delivery Time

With 5 CNC milling and turning machines, samples can be delivered within 7 days, and small batches can be delivered within 10 days. Conventional materials are stocked abundantly, and production operates 24/7.

Cost Reduction

Free optimization and Design for Manufacturability (DFM)manufacturability optimization to reduce costs. A high yield rate minimizes exceptions between sample and mass production, with prompt response to save the cost for the clients.

High Product Yield

Masion has ten quality control processes for control, layer upon layer, ensuring a 99% product quality rate.Instilling confidence in our customers that they will receive CNC machining products in highest standards.

Production Capacity

With advanced CNC turning and milling Machine and 15 years of experience as a CNC milling and turning manufacturer, the company has processed tens of thousands of product cases and employs skilled machinists.

Rapid Production

Masion is committed to quickly and efficiently cooperating with customers to verify the structure and appearance of the CNC machining parts, ensuring timely feedback and seamless collaboration throughout the manufacturing process.

How do we guaranty the quality?

Man

Excellent production and management managers work in Masion for the CNC milling and turning.Programmer and process engineers, skilled machinist with over 10 years of experience, and a production manager who was previously an engineer at a Taiwanese company. They have rich experience and strict management, aiming to deliver high-quality products on time.

Machine

High-precision CNC milling and turning machines, with a feed rate of 0.3mm(0.012inch), low surface roughness, and a dimensional accuracy of ±0.002mm(0.0000787inch). Software for CNC milling and turning machining: Professional CAM software for precise CNC milling and turning. The tools and fixtures are set up once, and the product is milled and turned in one operation. This ensures stable machining with a feed rate of 0.3mm, low surface roughness, and a dimensional accuracy of ±0.002mm(0.0000787inch), avoiding human errors in manual operations.

Environment

Clean and well-organized machining workshop further ensures the precision of CNC turning milling parts.

Materials

Incoming material spectral inspection, no mixing of materials, ensuring the physical properties of custom CNC turning milling parts for customers. During the incoming material inspection, the dimensions and material reports are checked to quickly identify the authenticity of the materials. If required by the customer, material reports can be provided for their convenience.

Method

By strictly implementing the ISO 9001:2015 quality management system, every CNC turning milling parts is ensured to meet the quality standards. In-process inspections and final inspections using CMM (Coordinate Measuring Machine) guarantee the quality requirements are met before shipment.

CNC Turning and Milling Machining Materials

| Picture | Material | Brief Introduction | Material Trademark | Surface Finish | Learn More |

|---|---|---|---|---|---|

| Aluminum Alloy | Aluminum alloy exhibits low density, high strength, high ductility, corrosion resistance, easy strengthening, surface treatment, good conductivity, recyclability, and cost-effectiveness. | AL5052-T651, AL6061-T651, AL 7075-T651, AL6082-T651 etc | A. Polishing, B. Grinding, C. Radium carving, D. Bead Blasting, E. Painting, F. Coating, G. Anodizing, H. Hard anodizing, I. Teflon Coating, J. Laser marking, K. Silk printing, L. Silk transfer printing | Learn More |

| Brass | Brass is an alloy composed of copper and zinc. High strength, good ductility, excellent mechanical properties, high wear resistance, good corrosion resistance, and lower price. | H58 H59、H62、HA177-2、HMn58-2、HPb59-1、HSn62-1 | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn More |

| Bronze | Bronze is an alloy of copper, tin, and lead with varying tin content (3% to 14%), known for its low melting point, high strength, castability, and corrosion resistance. | QSn-6-6-3 QSn10-1 QSn6.5-0.1 QSn7-0.2 QSn8-0.3 QSn4-0.3 QSn4-3 | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn More |

| Copper | High copper content, ranging from 99.5% to 99.95%. High density, melting point, excellent electrical conductivity, thermal conductivity, ductility, and corrosion resistance. | T1、T2、T3、TU1、TU2b | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn More |

| Magnesium alloy | Magnesium alloy is an alloy composed of magnesium and other elements. High strength, low density, with a density of approximately 1.8g/cm3, large elastic modulus, excellent heat dissipation, and remarkable impact resistance. | AZ31、AZ41、AZ61 | A. Polishing, B. Brushing, C. Bead Blasting, D. Micro-arc oxidation | Learn More |

| Stainless Steel | Low chromium content, 10.5%, high carbon content, 1.2%. High hardness, wear resistance, and high corrosion resistance. | 201、303、304、316、410、420、17-4PH | A. Polishing, B. Grinding, C. Vacuum heat treatment, D. Bead Blasting, E. Painting, F. Nitriding, G. Passivation, H. Zinc plating,J. Teflon, K. Titanium Coating, L. Laser marking, M. screen printing, N. transfer printing。 | Learn More |

| Titanium alloy | Titanium alloy is an alloy made from multiple types of titanium and other metals. Excellent strength, corrosion resistance, and heat resistance. | 1,2,3,4,5 Grade | A. Polishing, B. Grinding, C. Brushing, D. beadblasting, E. Laser marking, F. Screen printing, G. Transfer printing. | Learn More |

| Plastic | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | POM PEEK HDPE PET Nylon PTFE PVC PP ABS PC PMMA | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn More |

| Plastic | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | POM PEEK HDPE PET Nylon PTFE PVC PP ABS PC PMMA | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn More |

| Plastic | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | POM PEEK HDPE PET Nylon PTFE PVC PP ABS PC PMMA | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn More |

| Plastic | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | POM PEEK HDPE PET Nylon PTFE PVC PP ABS PC PMMA | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn More |

| Plastic | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | POM PEEK HDPE PET Nylon PTFE PVC PP ABS PC PMMA | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn More |

| Steel | Steel is an iron-carbon alloy with carbon content ranging from 0.02% to 2.11%, including carbon steel and ultra-high-strength steels. | 45#、40Cr、42CrMo、42CrMoB7 | A. Polishing, B. Grinding, C. Nitriding, D. Bead Blasting, E. Painting, F. Radium carving, H. Hard anodizing, I. Passivation, J. Galvanizing, K. Electroless nickel plating, L. Chrome plating, M. blackened/oxidized black, O. Teflon, P. Titanium coating, Q.LC coating, R. Laser marking, S. Silkscreen, T. Transfer Printing | Learn More |

Surface Finish of CNC Turning Parts

| Picture | Process | Spec | Material | Colors | Appearance | More |

|---|---|---|---|---|---|---|

| Dacromet | Dacromet is a corrosion-resistant coating with zinc and aluminum powder, chromic acid, and deionized water. It offers high permeability, adhesion, anti-friction, and chemical stability without environmental pollution. | Iron and steel and non-ferrous metals such as aluminum, magnesium and another alloys, copper, nickel, zinc and etc. | Red, silver, white, black, blue, green, yellow, etc. | Matte, Glossy or semi-glossy | Learn more |

| Electrophoresis | Electrophoresis is a coating process that applies a colored paint film for corrosion resistance, wear resistance, aesthetics, or special functions. | Aluminum, steel, stainless steel, Magnesium alloy, zinc alloy, etc. | Red, green, blue, purple, white, black, etc. | Glossy or Matte | Learn more |

| Electroplating | Electroplating applies a thin metal layer onto a metal surface to prevent oxidation, improve properties, and enhance appearance. Common processes include chromium, nickel, gold, silver, and tin plating. | Copper, cast iron, steel and stainless steel, aluminum, ABS plastics, polypropylene, polysulfone and phenolic plastics, etc. | Red, yellow, gold, green, blue, purple, rose gold, titanium, white, black, etc. | Glossy or Matte | Learn more |

| Polishing | Polishing is a surface treatment that reduces roughness, providing a smooth and bright finish. It removes imperfections, scratches, and restores paint appearance. | Copper, cast iron, steel and stainless steel, aluminum, magnesium alloy, titanium alloy, etc. | N/A | Glossy | Learn more |

| Anodizing | Anodizing is an electrochemical process that forms an oxide film on metal surfaces, improving corrosion resistance, wear resistance, hardness, and aesthetics. | Aluminum alloy, magnesium alloy, titanium alloy, etc., | Clear, black, grey, red, blue, gold,yellow, violet, double colors, camouflage color, etc. | Learn more | |

| Bead Blasting | Compressed air propels abrasive materials to remove rust, stains, and paint, and grind down burrs, achieving a renewed appearance on metal surfaces. | Cast iron, steel, stainless steel, aluminum alloy, magnesium alloy, titanium alloy, ABS, etc. | N/A | Matte | Learn more |

| Powder Coating | Plastic spraying applies electrostatic powder coating onto metal surfaces, providing corrosion protection, wear resistance, and aesthetic appeal with various colors. | Cast iron, steel, aluminum alloy, magnesium alloy, ABS and various plastics, etc. | Black, white, blue, green, yellow, purple, all the colors on the Pantone color card | Matte or glossy | Learn more |

| PVD(Physical Vapour Deposition) | PVD vaporizes materials to deposit functional films onto surfaces, improving appearance, hardness, wear resistance, corrosion resistance, and extending product lifespan. | Iron, stainless steel, aluminum alloy, titanium alloy, copper, ceramics, tungsten steel, zinc alloy, ABS and various plastics | Gold, gun black, coffee, purple, heptagon, royal blue, azure blue, black, titanium gray, so why bowl, rose gold, gold, champagne gold, etc. | Glossy | Learn more |

CNC Milling and Turning Service FAQs

CNC compound CNC milling and turning, also known as mill-turn machining or multi-tasking machining, combines both CNC milling and turning operations into a single process. It involves the use of a CNC machine that integrates milling and turning capabilities, allowing for the complete machining of a part without the need for multiple setups or machine changes. In CNC compound machining, the machine tool is equipped with multiple axes and tooling options to perform both milling and turning operations. The workpiece is held in place by a chuck or a collet, and the machine tool’s spindle rotates the workpiece while the cutting tools move along the necessary axes to perform the milling and turning operations.

Masion has production and machining experience in CNC milling and turning with a wide range of materials. Some common materials that can be used in CNC milling and turning include:

Metals: CNC milling and turning can be performed on various metals, such as aluminum, steel, stainless steel, brass, copper, titanium, and alloys like Inconel and Hastelloy.

Plastics: Different types of plastics can be CNC milled and turned, including ABS, acrylic, polycarbonate, nylon, PVC, PEEK, and Delrin.

Maison has accumulated production experience in industries such as beauty, automotive parts, electronics, robotics, drones, healthcare, and agriculture. Additionally, their composite milling products are also applied in industries such as aerospace, defense, semiconductors, maritime, and food.

Usually 200mm(7.87inch) in diameter and 600mm(23.62inch) in length.

0.002mm(2 microns 0.0000787inch).

Yes, we have advanced composite milling equipment that can efficiently process various complex components. It is worth mentioning that we specialize in machining various accessories for unmanned aerial vehicles (UAVs), such as wings, propellers, and fuselage shells. Additionally, we are capable of manufacturing articulated reduction shells for both bipedal and quadrupedal robots. Furthermore, we have extensive experience in the aerospace, maritime, and medical fields, allowing us to handle a wide range of complex components to meet our customers’ needs.

In general, the production of a sample typically takes about 7 days, depending on the requirements and complexity. This timeframe includes various stages such as design, prototype production, testing, and verification. For small-scale production, which involves producing a certain quantity of products after the sample has been validated, additional time is usually required to adjust and optimize the production process. Therefore, it usually takes around 10 days for small-batch production. On the other hand, large-scale production involves manufacturing a significant quantity of products, which generally requires more time to complete. This process typically takes approximately 20-25 days and involves various stages such as material preparation, equipment setup, workforce allocation, continuous production, quality control, and packaging. In summary, the time required for sample production and manufacturing depends on specific requirements and scale. Different scales and levels of complexity in production tasks necessitate varying timeframes for completion.

Typically, we calculate the cost of an individual workpiece based on its complexity and processing time. In the market, costs are generally measured based on the processing time, usually ranging from $9 to $12 per hour. This approach helps reflect the difficulty of processing the workpiece and the time required, thus aiding in determining the cost.

Yes, CNC milling and turning machines are commonly used for producing prototypes. Maison CNC milling and turning machines, in particular, are capable of processing rapid prototyping products. These machines combine turning and milling technologies into a single unit, enabling the quick manufacturing of prototypes for cylindrical or rotating parts like shafts, connectors, and fittings. The versatility and flexibility of Maison machines allow us to cater to the diverse needs of our customers and efficiently produce rapid prototype orders to meet the requirements of market development.

We are open to collaborating with customers from various backgrounds and offer customized rapid prototyping services. Whether you are an individual developer in need of custom parts or a large manufacturing company, we are equipped to provide you with high-quality and high-precision rapid prototyping services tailored to your specific requirements and designs.

Yes. Masion specialized in handle small batch orders in CNC milling and turning and we will assist clients in producing small batch products for market testing and collaborate with them to drive the growth of orders.

Typically, design changes are not feasible once the product design has entered the production stage. However, Masion can provide maximum assistance to clients even if the design is already in production. If there is a need to modify the design for some reason, we will immediately halt production and collaborate with the client to improve and enhance the design. This ensures that clients can have 100% trust in us. Although such a production stoppage may result in material and time wastage, we will make every effort to minimize losses.

We utilize DOOSAN CNC milling and turning machines for our operations. DOOSAN is a reputable brand known for its high-quality and reliable CNC machines.Their machines offer advanced features and precision control, allowing us to achieve accurate and efficient milling and turning processes. With DOOSAN equipment, we can handle a wide range of machining projects, from small to large-scale productions, while maintaining excellent quality and meeting customer specifications.

Yes, our CNC milling and turning machines are equipped with multi-axis capabilities. We have 4-axis and 5-axis machines that allow us to efficiently manufacture complex parts. The additional axes provide increased flexibility and precision in machining operations, enabling us to achieve intricate geometries and perform simultaneous machining on multiple sides of the workpiece. This capability helps us meet the demands of diverse and challenging projects.

Free Sample

Explore Other Services

CNC Turning Services

https://youtu.be/TfLpTK81Lw0 As a professional CNC turning manufacturer, supplier, and factory, Masionis dedicated to delivering high-precision CNC turning parts with a strong focus on cost-effectiveness. With our advanced CNC lathes, we

Wire Edm Machining

What is EDM Machining – Electrical Discharge Machining Definition https://cncmasion.com/wp-content/uploads/2023/11/390137809503.mp4 Electrical discharge machining or EDM, also known as spark machining or spark eroding, is a metal fabrication process and non-traditional

CNC Swiss machining

Specialized in CNC Swiss Machining Services –Leading CNC Swiss machining Companies/Manufacturers in China. What is CNC Swiss Machining? CNC Swiss machining is an advanced and rapid CNC machining technique. The