CNC Swiss machining

CNC Swiss machining

Specialized in CNC Swiss Machining Services –Leading CNC Swiss machining Companies/Manufacturers in China.

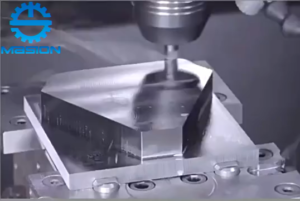

What is CNC Swiss Machining?

CNC Swiss machining is an advanced and rapid CNC machining technique. The main spindle holds the workpiece and moves back and forth along the axial direction. By utilizing multiple tool holders or turrets, specialized tools such as milling cutters, turning tools, twist drills, screw taps, boring cutters, and reamers perform multi-axis operations along the X, Z, and Y axes. This enables milling, turning, drilling, tapping, boring, engraving and other machining operations to be completed in a single setup, making it fit for machining small parts under 38mm in diameter. CNC Swiss Machining is suited for high-volume quantity, small-sized products, offering more cost-effectiveness and higher precision than other turning and milling processes.

CNC Swiss Machining Services

Are you looking for a CNC Swiss machining company, supplier, or manufacturer? We are a professional CNC Swiss machining company and manufacturer, offering our services as suppliers for a wide range of CNC Swiss Turn Parts. Our expertise lies in the manufacturing of precision parts such as medical bone screws, dental nails, ultrasonic knives, medical surgical stainless steel vertebral bodies, medical surgical stainless steel scrapers, medical surgical stainless steel square chisels, beauty products, shaft parts, valve parts, sleeve parts, lock parts, electrical parts, and more.

We specialize in customized Swiss turn parts for various industries, including medical, aerospace, automotive, electronics, telecommunications, refrigeration, optics, home appliances, etc. Our commitment to precision and efficiency is backed by our advanced Japanese 5 and 6-axis Swiss CNC Lathes, ensuring accurate and reliable machining processes.

What We do

Sports, 3C Electronics, Communications, Auto Parts, Aerospace Industry, Medical Equipment, Petrochemical Industry, new energy, and other industries.

Masion’s CNC Swiss Machining expertise extends to various industries, including outdoor sports equipment, medical devices, automobiles, beauty products, etc.

Swiss CNC Machining Automotive Parts

Swiss CNC Machining Clock and Watch Components

CNC Swiss Machining Beauty Parts

Why Choose Us

Rich Experience

Masion specializes in CNC Swiss turn parts. Our expertise ensures precise and reliable solutions for your specific needs.

Quality Control

Experienced and professional inspection team to improve product quality.100% inspection and quality assurance.

Machining Accuracy

Masion’s Swiss CNC machining accuracy: ±0.002mm, The coaxial degree:±0.002mm, and parallelism : is ±0.001mm

Technical Strength

Masion adheres to Taiwan’s CNC Swiss Lathe experience, following a strict precision manufacturing process.

Quality Service

Timely communication of production progress with customers, 3+1 service, on-time delivery.

Production Lead Time

Samples can be delivered in 7 days, and small batch production in 10 days. Batch order could be in 20-25days

Cost Reduction

Free optimization and manufacturability optimization to reduce costs. A high yield rate minimizes exceptions between sample and mass production,

High Product Yield

Masion has ten quality control processes for control, layer upon layer, ensuring a 99% product quality rate.

Production Capability

As a Swiss CNC machining company/manufacturer with 15 years of experience and thousands of product cases machining experience.

Fast Production

Masion is committed to quickly and efficiently to verify the structure of the CNC Swiss turn parts, ensuring timely feedback and seamless collaboration.

How do We Guaranty the Quality?

Man

Excellent production and management personnel equipped with CNC Swiss Machining. Programming masters and process engineers with over 10 years of experience, skilled operators, and a production manager who is an experienced engineer from a Taiwanese company, ensuring strict management and on-time delivery of high-quality products.

Machine

Japanese imported high-precision Swiss CNC Lathe with a dimensional accuracy of ±0.003mm and surface finish of Rα0.04-0.01μm.

Environment

Clean and tidy machining workshop to further ensure the accuracy of Swiss CNC machining.

Materials

Incoming material inspection and no mixing of materials to ensure the physical properties of custom Swiss machine parts. Material authenticity is quickly identified by inspecting material dimensions, material composition reports, and other material characteristics during the material intake process.

Method

Strict adherence to ISO 9001:2015 quality management system to ensure every Swiss CNC machining meets the requirements. Three-coordinate measurement and two-dimensional inspection ensure the quality of the final products.

What Types of Materials can be Effectively Machined

Using CNC Swiss Machines?

| Picture | Material | Brief Introduction | Material Trademark | Surface Finish | More |

|---|---|---|---|---|---|

| Aluminum Alloy | Aluminum alloy: Low density, high strength, high ductility, corrosion resistance, easy to strengthen, surface treatment, good conductivity, recyclability, and low cost. | AL5052-T651, AL6061-T651, AL 7075-T651, AL6082-T651 etc | A. Polishing, B. Grinding, C. Radium carving, D. Bead Blasting, E. Painting, F. Coating, G. Anodizing, H. Hard anodizing, I. Teflon Coating, J. Laser marking, K. Silk printing, L. Silk transfer printing | Learn More |

| Brass | Brass is an alloy composed of copper and zinc. High strength, good ductility, excellent mechanical properties, high wear resistance, good corrosion resistance, and lower price. | H58 H59、H62、HA177-2、HMn58-2、HPb59-1、HSn62-1 | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn More |

| Bronze | Bronze: Copper alloy with tin (3-14%) and lead, low melting point, high strength, excellent castability, chemical stability, ductility, wear resistance, corrosion resistance, and vibrant color. | QSn-6-6-3 SAE660 | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn More |

| Copper | High copper content, ranging from 99.5% to 99.95%. High density, melting point, excellent electrical conductivity, thermal conductivity, ductility, and corrosion resistance. | T1、T2、T3、TU1、TU2b | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn More |

| Magnesium alloy | Magnesium alloy: High strength, low density (approx. 1.8g/cm3), large elastic modulus, excellent heat dissipation, and remarkable impact resistance. | AZ31、AZ41、AZ61 | A. Polishing, B. Brushing, C. Bead Blasting, D. Micro-arc oxidation | Learn More |

| Stainless Steel | Low chromium content, 10.5%, high carbon content, 1.2%. High hardness, wear resistance, and high corrosion resistance. | 201、303、304、316、410、420、17-4PH | A. Polishing, B. Grinding, C. Vacuum heat treatment, D. Bead Blasting, E. Painting, F. Nitriding, G. Passivation, H. Zinc plating,J. Teflon, K. Titanium Coating, L. Laser marking, M. screen printing, N. transfer printing。 | Learn More |

| Titanium alloy | Titanium alloy is an alloy made from multiple types of titanium and other metals. Excellent strength, corrosion resistance, and heat resistance. | 1,2,3,4,5 Grade | A. Polishing, B. Grinding, C. Brushing, D. beadblasting, E. Laser marking, F. Screen printing, G. Transfer printing. | Learn More |

| Steel | Steel is an iron-carbon alloy with carbon content ranging from 0.02% to 2.11%, including carbon steel and ultra-high-strength steels | 45#、40Cr、42CrMo、42CrMoB7 | A. Polishing, B. Grinding, C. Nitriding, D. Bead Blasting, E. Painting, F. Radium carving, H. Hard anodizing, I. Passivation, J. Galvanizing, K. Electroless nickel plating, L. Chrome plating, M. blackened/oxidized black, O. Teflon, P. Titanium coating, Q.LC coating, R. Laser marking, S. Silkscreen, T. Transfer Printing | Learn More |

What is the Surface Finish of Swiss Turn Parts?

| Picture | Process | Spec | Material | Colors | Appearance | More |

|---|---|---|---|---|---|---|

| Electrophoresis | Electrophoresis: Coating process for corrosion resistance, wear resistance, aesthetics, or special functions. | Aluminum, steel, stainless steel, Magnesium alloy, zinc alloy, etc. | Red, green, blue, purple, white, black, etc. | Glossy or Matte | Learn More |

| Electroplating | Electroplating: Electrolytic process for metal surface enhancement, corrosion resistance, conductivity, and appearance. | Copper, cast iron, steel and stainless steel, aluminum, ABS plastics, polypropylene, polysulfone and phenolic plastics, etc. | Red, yellow, gold, green, blue, purple, rose gold, titanium, white, black, etc. | Glossy or Matte | Learn More |

| Polishing | Polishing: Surface machining for smooth, bright finish by removing imperfections and enhancing appearance. | Copper, cast iron, steel and stainless steel, aluminum, magnesium alloy, titanium alloy, etc. | N/A | Glossy | Learn More |

| Anodizing | Anodizing: Electrochemical process forms oxide film for improved properties and surface protection. | Aluminum alloy, magnesium alloy, titanium alloy, etc., | Clear, black, grey, red, blue, gold,yellow, violet, double colors, camouflage color, etc. | - | Learn More |

| Bead Blasting | Sandblasting: Uses compressed air to propel abrasive materials, removing rust and achieving surface renewal. | Cast iron, steel, stainless steel, aluminum alloy, magnesium alloy, titanium alloy, ABS, etc. | N/A | Matte | Learn More |

| PVD(Physical Vapour Deposition) | PVD: Vaporizes materials to form functional films with improved appearance, hardness, and durability. | Iron, stainless steel, aluminum alloy, titanium alloy, copper, ceramics, tungsten steel, zinc alloy, ABS and various plastics | Gold, gun black, coffee, purple, heptagon, royal blue, azure blue, black, titanium gray, so why bowl, rose gold, gold, champagne gold, etc. | Glossy | Learn More |

Swiss Machining Service FAQs:

Masion has extensive expertise in CNC Swiss machining with a rich experience of over 15 years. Our dedicated team comprises skilled machinists, designers, and engineers who specialize in the precision machining of a wide range of products, including valve sleeves, shafts, and bone screws.

Certainly! When we receive a drawing or project specifications from a client, we can showcase our previous workpieces that align with similar products or requirements. This helps the client gain a clear understanding of our capabilities and the quality of our previous projects. We are committed to providing relevant examples to demonstrate our expertise and assure clients of our ability to meet their specific needs.

We have the capability to accommodate a maximum outer diameter (OD) of 26mm and a minimum size of 0.3mm in our Swiss Machining process. This range allows us to work with a wide variety of part sizes, providing flexibility to meet diverse customer requirements.

Typically, we can achieve a high level of precision with tolerances as tight as ±0.001mm. Our advanced Swiss Lathe and skilled operators enable us to consistently meet these stringent tolerances, ensuring the accuracy and quality of the machined parts we produce.

Our Swiss Lathe is capable of working with a wide range of materials. We have experience machining materials such as aluminum, titanium alloy, steel, stainless steel, copper, and brass as well as various types of plastics. Our expertise in Swiss machining enables us to handle these materials efficiently and deliver high-quality results for our customers.

Absolutely. Our team of experienced engineers and machinists is well-equipped to handle the machining of complex parts. They possess a wealth of expertise in process analysis and are skilled at manufacturing parts with intricate features. We closely follow the specified requirements to ensure the precise production of complex geometries, allowing us to meet the unique needs of our customers.

Certainly! Our team of engineers is experienced in providing guidance and suggestions for design optimization specifically tailored to the Swiss Machining process. Upon reviewing the customer’s drawings, we can make adjustments and modifications to ensure the design is optimized for production on our Swiss Lathes. This collaborative approach allows us to enhance manufacturability, improve efficiency, and optimize the overall machining process to meet our customers’ needs.

Typically, the lead time for Swiss Machining projects ranges from 30 to 45 days. However, the actual timeframe may vary depending on factors such as the quantity and complexity of the product. It’s important to note that we have a significant advantage in meeting shorter lead times due to our extensive capacity, with over 20 sets of Swiss machines available for machining. This allows us to efficiently handle projects and deliver results within shorter timeframes when required.

Absolutely! At Maison, we prioritize supporting our customers in their manufacturing needs. We are capable of accommodating both small-scale orders and larger production runs. Whether it’s a small initial order that gradually expands over time or a large-scale order placed directly, we are committed to providing competitive prices, CNC Swiss Machining parts of excellent quality, and the highest level of service to meet our customers’ requirements.

Yes, we offer a comprehensive one-stop service to meet our customers’ needs. In addition to CNC Swiss Machining, we provide a range of additional services such as deburring, surface finishing, assembly, and packaging. Our skilled team is equipped to handle these processes, ensuring that the final products meet the highest quality standards and are ready for use or distribution.

We have established a comprehensive quality control system to ensure the highest standards in Swiss Machining. Our quality control measures include the implementation of the 4M 1E methodology. This involves various inspections and checks, such as first article inspection to verify initial samples, in-process monitoring to track quality during production, pre-shipment checks to ensure final product integrity, critical dimension measurements for precise dimensional accuracy, and more. These rigorous measures are implemented at every stage of the machining process to guarantee exceptional quality, meet customer specifications, and ensure overall satisfaction.

We strictly adhere to the ISO 9001 quality management system standards, which serve as the foundation of our operations. By following these internationally recognized guidelines, we maintain consistent quality across all aspects of our processes, continuously improve our performance, and provide reliable products and services to our valued customers.

We process customized products according to our customer’s specifications, ensuring the desired surface finish and smoothness as per their requirements. Additionally, we are equipped with roughness testing equipment to accurately assess and verify the surface roughness of our products. This allows us to maintain the highest level of precision and meet our customers’ exacting standards.

To ensure the accuracy and consistency of the machined parts, we employ several measures. Firstly, we utilize advanced equipment, such as Citizen CNC Swiss Lathe, known for their precision and control over dimensional tolerances. These machines are equipped with cutting-edge technology to deliver accurate and consistent results. Additionally, we have a quality control process in place that involves the use of advanced testing instruments like Coordinate Measuring Machines (CMM) and project meters. These instruments enable us to inspect and verify the dimensional tolerances of the machined parts, ensuring they meet the required specifications and maintaining consistent quality throughout the production process.

Our pricing structure primarily revolves around a per-part basis. However, we do consider various factors, including the complexity of the part and the time required for project completion, when determining the final pricing for our services. By taking into account these factors, we ensure a fair and accurate pricing assessment that reflects the intricacy and effort involved in machining the parts or completing the project.

Our standard payment terms involve a 30% deposit upon order confirmation and the remaining 70% balance prior to shipment. However, we understand that each project and product may have unique requirements, so we are open to discussing and finding mutually beneficial payment arrangements with our clients. As for payment methods, we accept various options such as bank transfers, credit cards, and other secure online payment platforms.

Free Sample

Explore Other Services

CNC Milling Services

Masion provides CNC Milling Services, specializing in the manufacturing of various CNC Milling parts, ensuring quality and quantity assurance.

Precision Machining Services

Precision Machining Services–Ultra Precision Machining Manufacturer If your product requires a very

Rapid Prototyping Manufacturing Services

China Rapid Prototyping Manufacturing Services-Your Trusted CNC and 3D Rapid Prototyping Manufacturer.