CNC Milling Services

CNC Milling Services

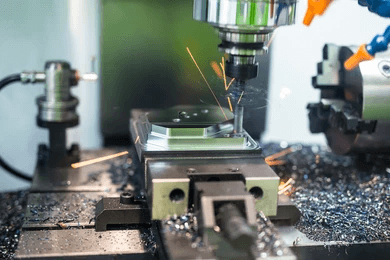

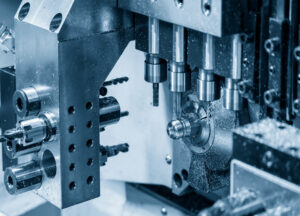

CNC Milling Services – Precision CNC Milling Parts Manufacturer & Supplier with 30 sets CNC Milling Machine.

Perhaps you’re still on the hunt for a professional, dependable CNC milling supplier, manufacturer, or factory. Well, it seems fate has led you to our website. We’re here to solve any problems you may have with your CNC milling products. Allow us to briefly introduce ourselves, our strengths, the products we offer, and our quick response action.

We’re a dedicated CNC milling machining services manufacturer, exporter, and supplier of CNC milling parts. We specialize in high-precision milling parts machining and reducing the cost of CNC milling parts. Our advanced CNC 3-axis, 4-axis, and 5-axis machining centers produce a wide range of products, including Prosthetic arthrosis Connector Accessories Parts, Metal anal expansion, N95 mask roller gear shafts, wheelchair part forks axis, prosthetic screw screws, step connecting blocks, machine dog shell bases, radiator aluminum shells, digital shells, drone electrical seats, camera cases, network player cases, skateboarding frames, skateboarding shafts, skateboarding wheels, fitness equipment accessories, skateboards, pedals of highway bicycles, fascia gun accessories, U disk shells, charging treasure shells, electronic cigarette cases, card reader housings, mobile phone camera holding fixed devices, game machine cases, and other three-dimensional products.

Masion offers high-quality CNC milling services in China, with competitive prices and faster delivery terms.

Masion has a high-precision advanced 3-axis, 4-axis, and 5-axis CNC machining center, a clean, well-organized production workshop, and an ISO9001 quality management system.

Masion excels in the efficient machining of milling parts with high accuracy and surface roughness, whether you require metal or plastic materials, prototype, or mass production. We could do everything in our power to work with you to deal with them.

With a maximum CNC milling machining capacity accuracy of +/-0.01mm, we provide a comprehensive test report, ensuring your project is in capable hands.

Types Of Multi-Axis CNC Milling

3-axis CNC Milling

3-axis machines efficiently handle four-sided machining, offering speed and cost-effectiveness. Ideal for various machining tasks, including graphic surfaces, curved surfaces, concave cavities, and negative angle surfaces like mold cavities, it can handle internal and external contours, holes, threads, etc. The 3-axis machine performs milling, boring, drilling, reaming, tapping, and other processes with automatic tool switching.

4-axis CNC Milling

Adding a shaft to the three-axis, four-axis CNC machine completes tasks the former cannot. Enhanced efficiency and fewer clamping instances characterize its use in machining polyhedral parts, helices, spiral grooves, cylindrical CAM, impellers, etc. The four-axis CNC machining center operates in two key modes: positioning and interpolation machining.

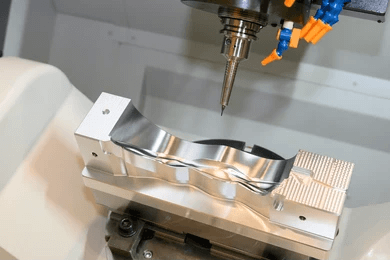

5-axis CNC Milling

Five-axis machining, with three linear coordinates (X, Y, Z) and two rotary axes (A, B), minimizes clamping, enabling intricate processing of complex shapes. Ideal for precision parts like impellers, blades, marine propellers, generator rotors, turbine rotors, and large diesel engine cranks, it ensures high precision, efficiency, short cycles, and excellent surface finish.

What We Do

CNC Milling materials

Cobalt, steel, alloy steel, aluminum alloy, titanium alloy, magnesium alloy, zinc alloy, beryllium alloy, stainless steel, brass, nickel alloy, bronze alloy, copper alloy, hard alloy, carbon steel, tungsten steel, plastic parts, etc.

Surface treatment capacity

Spray paint, Paint, Spray, Sandblasting, Shot blasting, Anodizing, Hard anodizing, Micro arc oxidation, Electroplating, Electrophoresis, Radial carving, Silk screen printing, Wire drawing, Mirror polishing, Dyeing, Blackening, CD pattern, Etching, Highlight, Etching, Glue drop, Chromic salt, PVD plating, Laser engraving, Magnetic polishing

One-stop CNC milling Services

Including Forging, Casting, Extrusion, Stamping, Casting, and Hot Forging, which saves a lot of costs.

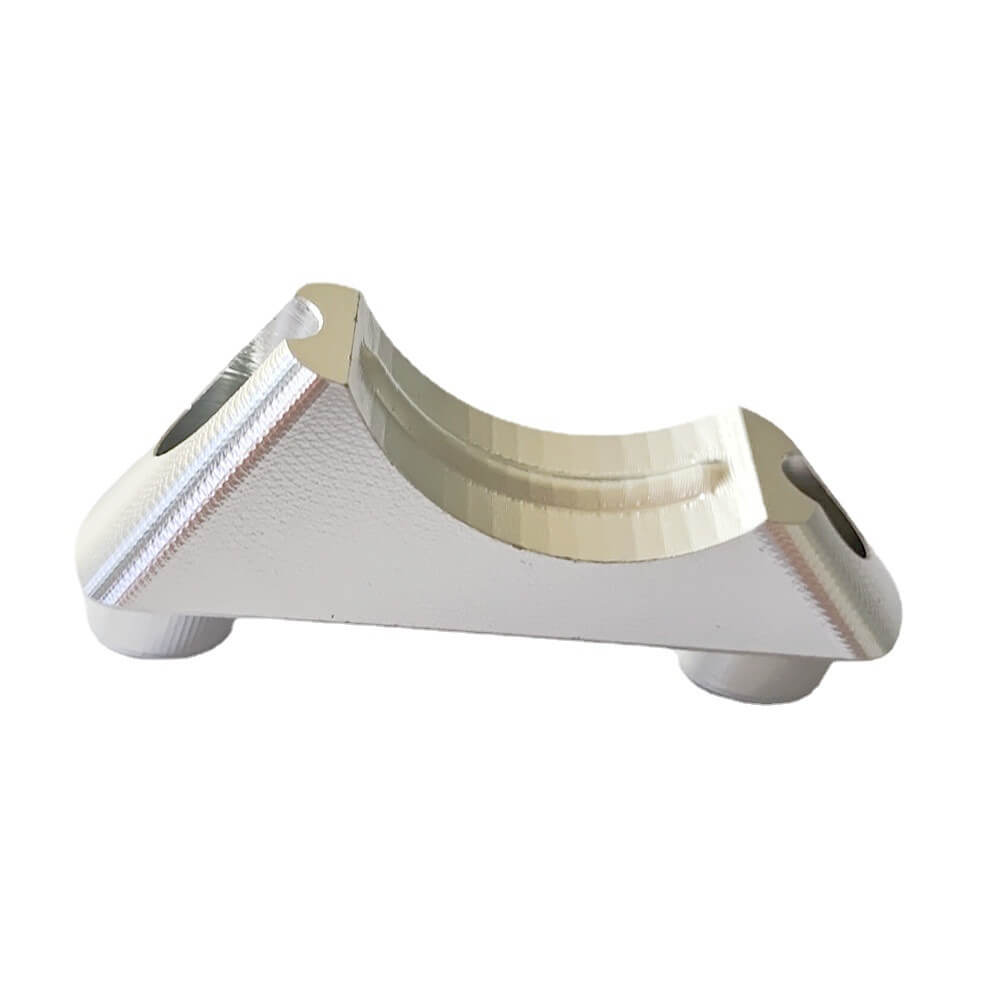

Our CNC Milling Parts

CNC Milling Machining applications: sports, 3C Electronics, Communications, Auto Parts, Aerospace Industry, Medical Equipment, Petrochemical Industry, new energy, and other industries.

Outdoor sports equipment CNC milling Part:

Scooter frames, scooter axles, scooter hubs, fitness equipment accessories, scooter brakes, road bike pedals, fascia gun accessories, and more.

Other CNC milling parts

Dog chassis bases, aluminum heat sink enclosures, digital enclosures, drone motor mounts, camera enclosures, network media player enclosures, Aluminum alloy precision measuring instrument cover plate base and more.

Medical CNC milling parts:

Orthotic accessory joint connectors, metal anal dilators, N95 mask machine roller gears, wheelchair parts such as front fork upright shafts, prosthetic screws, foot pedal connecting blocks, and more.

Automotive CNC milling parts:

New energy transmission casing, aluminum controller housing for new energy vehicle lithium battery compartments, engine cylinder block, new energy vehicle motor housing, engine housing, and more.

Electronic CNC milling parts:

USB flash drive shells, power bank shells, e-cigarette shells, card reader shells, cellphone camera clamps, game console shells, and so on.

Camera housing CNC milling parts:

such as AI camera case(housing), monitor case(housing), camera case(housing), video camera case (housing), industrial camera case(housing), Sensor Leap Case and so on.

Why Choose Us

Rich Experience

Currently, Masion has experience in CNC milling machining products for various industries, including outdoor, medical, auto parts, electronics, agriculture, communications, and more.

Excellent Service

We communicate timely with customers about production progress and provide 3+1 service for on-time delivery. Customer satisfaction is our standard and expectation.

Quality Control

Our lab features precision instruments, including 3D measurement, a projector, a scanner, a concentricity tester, etc. We conduct 100% inspection pre-shipment for worry-free quality.

Machining Accuracy

Our machining achieves ±0.01mm accuracy, and Rα0.63~5μm surface roughness, ensuring high-quality precision. It’s a solid foundation for projects, that exceed expectations.

Strong Technology

We adhere to Taiwan CNC milling machining and mature experience, following a strict precision manufacturing process.

Fast Delivery

We have over 30 sets of advanced 3-axis, 4-axis, and 5-axis CNC machines and can deliver samples within 7 days and small batches within 10-15 days. We maintain a sufficient inventory of conventional materials and operate 7*24 hours for production.

Cost Reduction

We offer a variety of CNC milling machining solutions to reduce production costs, providing free optimization and manufacturability optimization. We reduce costs through a high product yield of good products and respond quickly to abnormal situations after sample quantity.

High Product Yield

We have ten quality control processes in place for control, layer upon layer, ensuring a 99% product quality rate.

Production Strength

With advanced CNC milling Machine,3,4,5 axis CNC Machining center and over 15 years of experience in CNC milling manufacturing and tens of thousands of product cases machining experience, we have a team of experienced designers, mechanics, engineers, etc.

Rapid Production

We quickly cooperate with customers to verify structure and appearance.

How do We Guaranty the Quality?

Man

A group of exceptional production and management personnel, with over 10 years of extensive experience in CNC milling, aims to deliver high-quality products on time. The team comprises of a proficient programming master, experienced process engineer, and skilled operators. The production manager, a former engineer from a Taiwan company, brings a wealth of experience and strict management practices to the table.

Machine

Our CNC milling process is highly precise, with a dimensional accuracy of ±0.005 and a finish of Rα0.04 -- 0.01μm. Our milling CNC machining software includes a professional CAM software for precision milling machining that enables the development of milling processes and generates CNC programs with a single key, reducing the possibility of manual errors.

Environment

Our machining workshop is clean and organized, which enhances the accuracy of CNC milling machining.

Materials

We conduct strict inspections of incoming materials to ensure the physical properties of customized milling CNC machining parts. We determine the authenticity of raw materials quickly through composition, size, and material report testing.

Method

We strictly implement the ISO9001:2015 quality management system to ensure the quality of each CNC machining part. We perform Coordinate Measuring Machine product testing and project meter testing before shipment to meet quality requirements.

CNC Milling Machining Materials

| Picture | Material | Brief Introduction | Material Trademark | Surface Finish | More |

|---|---|---|---|---|---|

| Aluminum Alloy | Aluminum alloy: Low density, high strength, ductility, corrosion resistance, easy to strengthen and surface treat, good conductivity, recyclable, and cost-effective. | AL5052-T651, AL6061-T651, AL 7075-T651, AL6082-T651 etc | A. Polishing, B. Grinding, C. Radium carving, D. Bead Blasting, E. Painting, F. Coating, G. Anodizing, H. Hard anodizing, I. Teflon Coating, J. Laser marking, K. Silk printing, L. Silk transfer printing | Learn More |

| Brass | Brass is an alloy composed of copper and zinc. High strength, good ductility, excellent mechanical properties, high wear resistance, good corrosion resistance, and lower price. | H58 H59、H62、HA177-2、HMn58-2、HPb59-1、HSn62-1 | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn more |

| Phosphor Bronze | Bronze: copper alloy with added tin and lead (3%-14%). Low melting point, high strength, excellent castability, chemical stability, ductility, wear/corrosion resistance, and vibrant color. | QSn-6-6-3 SAE660 | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn more |

| Copper | High copper content, ranging from 99.5% to 99.95%. High density, melting point, excellent electrical conductivity, thermal conductivity, ductility, and corrosion resistance. | T1、T2、T3、TU1、TU2b | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn more |

| Magnesium alloy | Magnesium alloy: high strength, low density (approx. 1.8g/cm3), large elastic modulus, excellent heat dissipation, and remarkable impact resistance. Composed of magnesium and other elements. | AZ31、AZ41、AZ61 | A. Polishing, B. Brushing, C. Bead Blasting, D. Micro-arc oxidation | Learn more |

| Stainless Steel | Low chromium content, 10.5%, high carbon content, 1.2%. High hardness, wear resistance, and high corrosion resistance. | 201、303、304、316、410、420、17-4PH | A. Polishing, B. Grinding, C. Vacuum heat treatment, D. Bead Blasting, E. Painting, F. Nitriding, G. Passivation, H. Zinc plating,J. Teflon, K. Titanium Coating, L. Laser marking, M. screen printing, N. transfer printing。 | Learn more |

| Titanium alloy | Titanium alloy is an alloy made from multiple types of titanium and other metals. Excellent strength, corrosion resistance, and heat resistance. | 1,2,3,4,5 Grade | A. Polishing, B. Grinding, C. Brushing, D. bead blasting, E. Laser marking, F. Screen printing, G. Transfer printing. | Learn more |

| POM | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | POM-C POM-H | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn more |

| PMMA | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | Altuglas V825T、Altuglas V825、Altuglas V920 | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn more |

| PTFE | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | 008 1700 | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn more |

| PEEK | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | 8200 PEEK, PEEK 4500G, PEEK 1000 | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn more |

| ABS | Plastics have poor thermal conductivity, low coefficient of thermal expansion, and low elastic modulus. | ABS-GF30 AG15A1-H | Painting, F. radium carving, L. chrome plating, R. laser marking, S. silk screen, T. Transfer printing | Learn more |

| Steel | Steel: iron-carbon alloy with carbon content (0.02%-2.11%). Carbon steel has <1.7% carbon. Ultra-high-strength steels offer high strength, toughness, and good hardenability. | 45#、40Cr、42CrMo、42CrMoB7 | A. Polishing, B. Grinding, C. Nitriding, D. Bead Blasting, E. Painting, F. Radium carving, H. Hard anodizing, I. Passivation, J. Galvanizing, K. Electroless nickel plating, L. Chrome plating, M. blackened/oxidized black, O. Teflon, P. Titanium coating, Q.LC coating, R. Laser marking, S. Silkscreen, T. Transfer Printing | Learn more |

Surface Finish of CNC Milling Parts

Product surface finish can be highly specific to meet different customer demands. We provide various surface finish options to improve product quality, appearance, and market competitiveness. The surface finish for CNC milling parts is intended to enhance their appearance, surface hardness, roughness, chemical resistance, and corrosion resistance. Below are several common surface finish choices available, If you want to know more about surface finish. Please Learn More.

| Picture | Process | Brief introduction | Material | Colors | Appearance | More |

|---|---|---|---|---|---|---|

| Electrophoresis | Electrophoresis coats workpiece surface with colored paint film for corrosion resistance, wear resistance, aesthetics, or special functions. | Aluminum, steel, stainless steel, Magnesium alloy, zinc alloy, etc. | Red, green, blue, purple, white, black, etc. | Glossy or Matte | Learn more |

| Electroplating | Electroplating utilizes electrolytic principles to apply a thin metal layer for oxidation prevention, wear resistance, conductivity, reflectivity, and corrosion resistance | Copper, cast iron, steel and stainless steel, aluminum, ABS plastics, polypropylene, polysulfone and phenolic plastics, etc. | Red, yellow, gold, green, blue, purple, rose gold, titanium, white, black, etc. | Glossy or Matte | Learn more |

| Polishing | Polishing reduces surface roughness through mechanical, chemical, or electrochemical action, resulting in a smooth and lustrous finish, eliminating imperfections and enhancing paint appearance. | Copper, cast iron, steel and stainless steel, aluminum, magnesium alloy, titanium alloy, etc. | N/A | Glossy | Learn more |

| Anodizing | Anodizing is an electrochemical process forming oxide film on metals like aluminum, improving corrosion resistance, wear resistance, hardness, and surface appearance. | Aluminum alloy, magnesium alloy, titanium alloy, etc., | Clear, black, grey, red, blue, gold,yellow, violet, double colors, camouflage color, etc. | Learn more | |

| Bead Blasting | Compressed air propels abrasive materials to remove rust, stains, and paint from metal surfaces, achieving a renovated appearance by grinding burrs and scars. | Cast iron, steel, stainless steel, aluminum alloy, magnesium alloy, titanium alloy, ABS, | N/A | Matte | Learn more |

| Powder Coating | Plastic spraying electrostatically applies powder coating to metal surfaces, forming a protective film for corrosion resistance, improved appearance, and color options. | Cast iron, steel, aluminum alloy, magnesium alloy, ABS and various plastics, etc. | Black, white, blue, green, yellow, purple, all the colors on the Pantone color card | Matte or glossy | Learn more |

| PVD(Physical Vapour Deposition) | PVD vaporizes source materials and deposits functional films onto substrates, enhancing appearance, hardness, wear resistance, corrosion resistance, and service life. | Iron, stainless steel, aluminum alloy, titanium alloy, copper, ceramics, tungsten steel, zinc alloy, ABS and various plastics | Gold, gun black, coffee, purple, heptagon, royal blue, azure blue, black, titanium gray, so why bowl, rose gold, gold, champagne gold, etc. | Glossy | Learn more |

CNC Milling Services FAQs

CNC milling is a manufacturing process that uses computer numerical control (CNC) machines to remove material from a workpiece. It works by rotating cutting tools while the workpiece is held in place, allowing for precise shaping and machining.CNC Milling refers to the process of using rotating multi-blade cutting tools to cut the workpiece. It is an efficient machining method. During operation, the tool rotates (as the main motion) while the workpiece moves (as the feed motion). The workpiece can also be fixed, but in this case, the rotating tool must still move (to simultaneously perform both the main and feed motions).

CNC milling offers high precision, accuracy, and repeatability. It allows for complex geometries and can work with various materials. It also enables efficient production rates and can be used for both prototyping and production.

Industries such as aerospace, automotive, medical, electronics, and prototyping frequently utilize CNC milling services for their manufacturing needs.

Yes, CNC milling can be used to produce both simple and complex parts. It is highly versatile and can handle a wide range of geometries and designs.

For normal milling machines, they cannot change the tools, so they can only perform simple milling operations. However, CNC machining centers have multi-axis control capabilities such as 3-axis, 4-axis, and 5-axis. They are equipped with their own tool libraries and can perform uninterrupted tool changes. Additionally, the workpiece can rotate during the machining process. Therefore, for the machining of complex workpieces, 3-axis, 4-axis, and 5-axis CNC machining centers are usually chosen, while simple workpieces can be completed using regular milling machines.

Having accumulated years of experience in 5-axis machining, Masion is proficient in handling complex components, particularly impellers, wheel hubs, and automotive cylinder housings. With their extensive machining expertise, they are well-equipped to assist clients in resolving challenges related to intricate parts.

CNC milling can be used with various materials, including metals (such as aluminum, steel, and titanium), plastics, wood, and composites.

The primary difference between 3-axis, 4-axis, and 5-axis CNC milling lies in the number of axes of motion and the machining capabilities they offer.

Three-axis CNC milling: This setup involves three linear axes of motion, usually referred to as X, Y, and Z. The X-axis represents left and right movement, the Y-axis represents forward and backward movement, and the Z-axis represents up and down movement. Three-axis machines are suitable for machining parts with simple geometries, such as flat or slightly curved surfaces. However, they may face limitations when machining complex features or multiple faces that require angled cuts.

Four-axis CNC milling: In addition to the three linear axes, four-axis machines incorporate an additional rotational axis, often referred to as the A-axis. This rotational axis allows the workpiece to rotate 360 degrees in the horizontal plane. Additionally, some four-axis machines may have a second rotational axis called the B-axis, enabling the workpiece to rotate in the vertical plane. This setup enables more complex machining operations and offers increased flexibility. Four-axis machines are commonly used for machining parts that require drilling holes or milling features on multiple sides or curved surfaces.

Five-axis CNC milling: Five-axis machines take the capabilities of four-axis machines further by adding an additional rotational axis, usually called the B-axis, which provides a 360-degree rotation in the vertical plane. With five axes of motion (X, Y, Z, A, B), these machines offer the highest level of machining versatility. They can perform complex operations and reach difficult-to-access areas of a workpiece. Five-axis CNC milling is ideal for manufacturing intricate and precise parts that require multi-sided machining, such as aerospace components, medical implants, and complex molds.

In summary, as the number of axes increases from three to five, CNC milling machines become capable of handling more complex geometries, allowing for a wider range of machining operations and increased precision. The choice of the appropriate machine depends on the specific requirements of the part being produced and the desired level of complexity in the machining process.

Masion CNC milling machines(link to machine), including their 3-axis, 4-axis, and 5-axis machines, are recognized for their high accuracy in precision machining. These machines are capable of achieving tight tolerances of approximately ±0.01mm. This level of accuracy allows for the production of precise and intricate parts with consistent dimensions.

The time required to complete CNC milling parts can vary depending on factors such as the complexity of the part, the quantity being produced, the availability of the CNC machines, and the workload of the CNC milling service provider. However, as an example, Masion, with their 30 sets of CNC machining centers, typically takes the following timeframes:

Sample Production: Masion can complete the production of sample parts within approximately 7 days. This allows for testing and verification of the design before moving on to larger-scale production.

Small Order Production: For small orders, Masion usually requires around 10-15 days to complete the milling process and deliver the finished parts.

Mass Production: If you have a larger production quantity, Masion typically allocates around 20-25 days to complete the milling process and produce the desired quantity of parts.

It’s important to note that these timeframes are provided as examples and can vary depending on the specific project requirements and the workload of the CNC milling service provider. It’s recommended to consult directly with the service provider to get a more accurate estimate for your specific project.

Yes, CNC milling services can provide custom designs. Masion, for example, has three designers in our R&D department(链接到R&D) who can work with clients to create custom 2D or 3D CAD models. These designers can collaborate with clients to modify drawings and ensure that the desired part is accurately designed. Once the design is finalized, Masion can program our CNC machines to produce the custom part according to the specifications. CNC milling services often offer design and programming capabilities to meet the specific requirements and customization needs of their clients.

The maximum size of a workpiece that can be milled with CNC machines can vary depending on the specific CNC machine and its capabilities. However, as an example, a CNC machining center like Masion that you mentioned can typically work with a workpiece size of approximately 800mm in length, 800mm in width, and 500mm in height. Additionally, it can accommodate workpieces with a diameter of up to 500mm.

The cost considerations for CNC milling services include various factors that can influence the overall pricing. These factors typically include:

The complexity of the Part: More complex parts with intricate designs or tight tolerances may require additional machine setup time, specialized tooling, or multiple machining operations, which can increase the cost.

Material Selection: Different materials have varying costs, and certain materials may require special cutting tools or machining techniques, impacting the overall price.

Machine Setup Time: The time required to set up the CNC machine for a specific job can affect the cost. Complex setups or frequent changeovers may increase the setup time and, subsequently, the cost.

Quantity: The number of parts needed can impact the pricing. Larger production runs often benefit from economies of scale, leading to lower per-unit costs.

Additional Services: Any additional services required, such as surface finishing, heat treatment, or assembly, may add to the overall cost.

When providing CNC milling services, Masion considers these factors and provides individual workpiece quotations based on the customer’s drawings and specific requirements. An accurate price can be determined by assessing the complexity, material, quantity, and setup time. It is also worth noting that the general market quotation for CNC milling services often falls within the range of 9-11 USD per hour of machining, but this can vary based on the location and specific service provider.

Yes, Masion can provide a wide range of surface finishes and textures according to the project’s requirements in CNC milling services. This includes smooth finishes, textured patterns, and specific surface treatments like powder coating, anodizing, PVD, electrophoresis, electroplating, and more.

In order to ensure quality control in CNC milling services, Masion implements the following measures:

Material Inspection: Masion conducts thorough inspections of the incoming materials to verify their quality and suitability for the project.

In-Process Inspection: Regular inspections are performed during the milling process to monitor the quality and dimensions of the workpieces at different stages of production.

First Article Inspection: The first article produced is meticulously inspected to ensure it meets all the required specifications and tolerances.

Final Inspection: Before the completed workpieces are delivered, a final inspection is conducted to verify their overall quality, accuracy, and adherence to the customer’s specifications.

Advanced Inspection Equipment: Masion utilizes advanced equipment such as Coordinate Measuring Machines (CMM) and project meters to accurately measure and evaluate the workpieces’ dimensions, geometries, and surface finishes.

These quality control measures help Masion to identify any deviations or issues during the production process and ensure that the final products meet the required standards and customer expectations.

The CNC milling process typically involves design preparation, material selection, tooling setup, programming the machine, workpiece fixation, actual milling, post-processing (if required), and final quality checks.

Yes, Masion offers assembly and post-processing options as part of their CNC milling services. This includes workpiece assembly, where individual components are assembled to create the final product. Additionally, post-processing options such as surface treatment, custom packaging, and other finishing touches are also available to meet the specific requirements of the project.

- Equipment and capabilities: Make sure the provider has the necessary machining equipment and capabilities, such as 5-axis machining for complex parts.

- Experience and track record: Verify that the provider has relevant machining experience and a proven track record of successfully completing similar projects.

- Professionalism and technical support: Observe the professionalism of the sales representatives and inquire about the availability of dedicated engineers who can address your technical questions and concerns.

- Quality control measures: Ensure that the service provider has inspection equipment like CMM and project meter, particularly for complex parts, to ensure high-quality output.

- Sample availability and lead time: Confirm that the provider can deliver samples within a reasonable timeframe, allowing you to assess the quality and suitability of their work for your project.

- Pricing considerations: Evaluate whether the pricing offered by the service provider aligns with your budgetary requirements and provides good value for the services rendered.

By considering these factors, you can make an informed decision and select the right CNC milling service provider for your project.

When selecting a CNC machining service provider, the following factors should be considered:

- Does the factory have sufficient production capacity and necessary machines and facilities to support production?

- Does the factory have experience in producing similar products?

- Does the factory have advanced inspection devices to ensure product quality?

- Do the factory’s machinists follow standardized operating procedures and meet quality management standards?

- Are the lead times for sample production and large-scale production short?

- Does the factory’s pricing meet customer expectations?

- Can the communication personnel quickly understand customer requirements and provide solutions?

- Does the sample production meet the dimensional tolerances specified in the drawings?

Note: It’s worth mentioning that while the translation provided here is accurate, it is always recommended to review and proofread translations for the specific context or audience.

Free Sample

Explore Other Services

Automatic Machining

Automatic lathe machining Services – Precision Automatic lathe machining (turning) Parts Manufacturer & Supplier with 20 sets Automatic lathe machining Machine. Automatic Lathe Machining Services We are a professional manufacturer,

CNC Swiss machining

Specialized in CNC Swiss Machining Services –Leading CNC Swiss machining Companies/Manufacturers in China. What is CNC Swiss Machining? CNC Swiss machining is an advanced and rapid CNC machining technique. The

CNC Turning Services

https://youtu.be/TfLpTK81Lw0 As a professional CNC turning manufacturer, supplier, and factory, Masionis dedicated to delivering high-precision CNC turning parts with a strong focus on cost-effectiveness. With our advanced CNC lathes, we