Mirror Polishing

Mirror Polishing

Process Introduction of Mirror Polishing

Mirror polishing is a machining method that uses mechanical, chemical, or electrochemical actions to reduce the surface roughness of the workpiece and obtain a bright and smooth surface. It is a decorative processing of the workpiece surface using polishing tools and abrasive particles or other polishing media. Mirror polishing typically uses oil stones, wool wheels, sandpaper, etc., to remove the protruding parts of the workpiece surface through plastic deformation of the material surface and achieve a smooth surface, usually done by hand or by equipment. For surfaces with high quality requirements, the ultra-precision grinding and polishing method can be used. Ultra-precision grinding and polishing use specially designed abrasives, which are pressed tightly onto the surface of the workpiece being machined and rotate at high speed in a grinding and polishing solution containing abrasives. The surface roughness achieved by polishing can reach Ra0.008 μm. Mirror polishing is divided into mechanical mirror polishing and chemical solution mirror polishing. Mechanical mirror polishing involves a series of polishing processes (rough polishing, fine polishing) on metal materials to achieve a smooth and mirror-like surface. Chemical solution mirror polishing involves immersion in a chemical solution to remove surface oxide scale to achieve a bright effect.

Mirror Polishing Process Flow

Polishing process

Coarse polishing

Coarse polishing is to correct the rough surface and irregular shape.

Fine polishing

After coarse polishing, there are still deep scratches on the metal surface, which need to be eliminated in fine polishing to prepare for polishing.

Surface polishing process

Polishing is the last process for the plated surface or the surface of the part. Its purpose is to eliminate the fine scratches that still remain on the surface after the polishing process. The ideal polished surface should be a surface that is flat, bright, free of scratches, without floating patterns, pits, and metal disturbed layers, like a mirror. The polished surface changes after polishing and polishing.

Three-Step Mirror Polishing

Composite Louver Disc

The composite louver disc is a structure that combines surface polishing materials with coated abrasives, which can remove rough surfaces and irregular shapes and achieve rough and preliminary fine grinding.

Synthetic Polishing Disc

High-concentration abrasives are distributed on a sturdy non-woven fabric substrate to remove polishing or burrs on stainless steel surfaces, achieving fine grinding and preparing for polishing.

Wool Polishing Disc

The wool polishing disc is flexible and can easily accelerate the flow of air for cooling, making it suitable for use with polishing wax or paste. It is the last step in the process of processing metal surfaces to achieve a bright mirror-like finish.

Method Recommendation

Purpose

Used to remove the oxidation layer generated during the cold rolling and stamping process of stainless steel (screws, pendants, small hardware, decorations, etc.) and make it shiny and beautiful.

Features

Chemical polishing, quick and convenient, economically efficient, with good brightness, exceeding similar products in the market.

Usage

In the drum, use metal cleaning solution in a ratio of 1:20 with 90-degree hot water, add the workpiece to be polished, roll for 5-15 minutes, and clean the oil and dirt. Mix the polishing solution with water in a ratio of 1:20-50 to make a working solution, and polish by vibration or rolling for about 15 minutes. Rinse with clean water, centrifuge or air dry and hang to dry.

Note

The polished workpiece must be thoroughly degreased; the polishing solution is a concentrated liquid, and the ratio of adding water during polishing depends on the actual material conditions.

Packaging

Plastic bottle: 1 kg/bottle, 24 bottles/box; plastic drum: 25 kg/drum, 40 kg/drum.

Stainless Steel Dual-Purpose Polishing Solution

Purpose

To remove oil stains and oxidation from stainless steel (screws, pendants, small hardware, decorations, etc.) produced during cold rolling and stamping processes, and to make it shiny and beautiful.

Features

Chemical polishing, oil and polishing completed at one time, fast and convenient, economical and efficient, and with good brightness.

Usage

Mix the dual-purpose polishing solution with water in a ratio of 1:20-50 to form a working solution. Polish by vibrating or rolling for about 15 minutes, rinse with clean water, and then centrifuge, air dry, or hang dry.

Note

It is suitable for workpieces with light oil stains. The polishing solution is a concentrated liquid, and the water ratio during polishing depends on the actual material. Do not touch eyes or mouth. If accidentally touched, immediately rinse with water.

Packaging

Plastic bottles: 1 kg/bottle, 24 bottles/box; Plastic drums: 25 kg/drum, 40 kg/drum.

Stainless Steel Polishing Liquid

Usage

Used for polishing stainless steel products such as fasteners, fishing accessories, chains, pendants, springs, small hardware, etc. after processing. Compared with stainless steel drum polishing liquid, this product has a stronger acidity and is more suitable for polishing workpieces with an oxide layer or higher surface roughness.

Features

This product is formulated with cleaning agents, brighteners, corrosion inhibitors, surface-active agents, etc., which significantly improves the surface brightness of stainless steel parts, making them bright and beautiful. The combination of mechanical and chemical polishing is cost-effective and produces good brightness.

Instructions

The main function of this product is polishing, and it also has a quick-acting oxide removal function. It can be used in conjunction with stainless steel drum polishing liquid (06204). The first step is to use this product to remove surface burrs, oxide layers, sand eyes, etc. The second step is to use stainless steel drum polishing liquid (06204) for polishing to achieve better gloss. It can also be used alone.

Mixing

Pour the polishing liquid into the drum containing the stainless steel parts at a ratio of 2-3% by weight of the parts (or increase the amount according to the oxide layer situation), and then add twice the amount of water (i.e., polishing liquid: water = 1:1 to 1:2 after dilution).

Processing process

The drum rolls for polishing, and the time is based on the brightness of the workpiece, which is about 1-2 hours. The polishing liquid is then drained, rinsed with water, centrifuged, air-dried, or dried naturally.

Depending on the surface roughness of the workpiece, abrasive materials (such as polishing blocks) can be used in conjunction with the product, and the rolling time can be appropriately extended for workpieces with high roughness values such as stainless steel chains.

Note: 1.

This product is acidic and should not be placed in eyes or mouth. It can corrode the skin. If it comes into contact with skin, rinse with water immediately.

Note: 2.

Store in a cool place for long-term effectiveness.

Packaging

Plastic bottle: 1 kg/bottle, 24 bottles/box; plastic drum: 25 kg/drum, 40 kg/drum.

Stainless Steel Drum Polishing Liquid

Usage

Used for polishing stainless steel fasteners, fishing accessories, chains, pendants, springs, small hardware and other stainless steel products after processing.

Features

Formulated with cleaning agents, brightening agents, corrosion inhibitors, surface active agents, etc. It provides a mirror-like gloss, abundant foam, and long-lasting effectiveness.

Instructions

The main function of this product is polishing. The polishing process is a two-step method: first remove the oil, and then use this product for polishing.

Mixing

Pour 1-2% of the polishing liquid into a drum containing stainless steel parts, then add an equal amount of water to the polishing liquid (i.e., a 1:1 dilution of the polishing liquid with water).

Processing

Roll the drum for polishing, and the processing time depends on the brightness of the workpiece, which usually takes about 0.5-1 hour. After polishing, drain the polishing liquid, rinse with water, and then centrifuge, air dry or hang to dry. According to the roughness of the workpiece surface, abrasive materials (such as polishing blocks) can be used in conjunction with the polishing liquid.

Note

This product is acidic, and should not be ingested or come into contact with eyes. It may cause slight skin corrosion. Rinse with clean water if in contact with skin. Store in a cool, sealed place for long-term effectiveness.

Packaging

Plastic bottles: 1kg/bottle, 24 bottles/box; Plastic drums: 25kg/drum, 40kg/drum.

Factors Affecting Polishing

The accuracy of the gear before shaving has a significant impact on the accuracy of the processing after shaving. Generally, the required gear accuracy before shaving should be one level lower than that after shaving, and the requirement for the pitch is relatively high. Because shaving is not a forced transmission due to the lack of a transmission chain on the machine tool, its ability to correct pitch errors is relatively poor. Therefore, in general, rolling should be used instead of hobbing as much as possible in the pre-shaving process.

The amount of residual shaving should be appropriate. If the residual shaving is too small, the accuracy cannot meet the requirements, but if the residual shaving is too large, it will affect the efficiency of shaving. Someone has done experiments on a gear with a size of M4.5, and the most suitable range is 0.18mm-0.22mm. When the accuracy in the pre-shaving process is relatively good, the amount of residual shaving can be reduced.

The cutting amount of shaving also has a significant impact on the smoothness. Generally, the reasonable speed is 90-110 meters per minute, and the reasonable feed rate is 70-120 millimeters per minute. The most suitable polishing stroke is 6-8 times.

The tooth shape error generated by shaving also affects the smoothness. It is known from actual processing experience that although the tool is correct involute, the gear after shaving is not easy to obtain the correct involute and has errors. Relatively speaking, the error when using a straight-tooth shaving cutter to process a helical gear is smaller than when using a helical-tooth shaving cutter to process a helical gear (assuming that the shaft intersection angle is between 10-15 degrees). Because it is currently impossible to calculate the size of the shaving error, the tooth shape generally needs to be continuously corrected to meet the correct requirements.

Mirror Polishing Processing and Production Equipment Display

Display of Testing Equipment for Mirror Polishing Processing

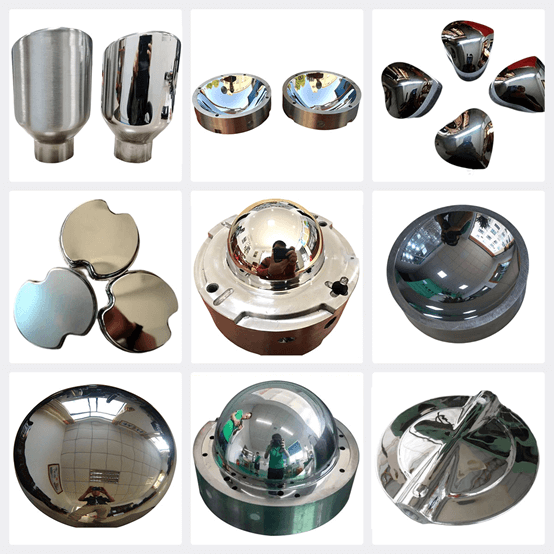

Sample cases of mirror polishing processing

Free Sample

Explore Other Surface Finish

Chemical Nickel Plating

Bead Blasting, also known as abrasive blasting or sandblasting,typically involves the use of compressed air to propel abrasive particles from a nozzle and direct them onto the surface to be

Chrome Plating

Bead Blasting, also known as abrasive blasting or sandblasting,typically involves the use of compressed air to propel abrasive particles from a nozzle and direct them onto the surface to be

Bright Tin Plating

Bead Blasting, also known as abrasive blasting or sandblasting,typically involves the use of compressed air to propel abrasive particles from a nozzle and direct them onto the surface to be