Passivation of Aluminum and Aluminum Alloys

Passivation of Aluminum and Aluminum Alloys

Abstract: For aluminum and aluminum alloy workpieces, whether obtained through chemical oxidation or anodization, the resulting oxide film is porous, prone to contamination, and has poor corrosion resistance. Even after coloration of the film, passivation and sealing treatment should be performed to enhance its corrosion resistance.

Passivation of Aluminum and Aluminum Alloys After Chemical Oxidation

Passivation treatment of aluminum and aluminum alloy workpieces with chemical oxide film is outlined in Table 1.

| Formulation No. | Solution Components | Content /g.L-1 | Temperature /℃ | Time | Baking Temperature | Remark |

|---|---|---|---|---|---|---|

| 1 | Potassium dichromate(K3Cr4O7) | 30~50 | 90~95 | 5~10min | ≤90 | Suitable for acid oxidation |

| 2 | Chromium oxide(CrO4) | 20 | Room temperature | 5~15s | ≤50 | Suitable for alkaline oxidation |

| Formulation No./Solution composition and process conditions | 1 | 2 |

|---|---|---|

| Potassium dichromate(K3Cr4O7) Potassium chromate(K2CrO4) Temperature/℃ Time/min | 40~70 80~95 10~20 | 50 80 20 |

Hot Water Sealing

(1) Principle

The Al2O3 on the surface and pore walls of the oxide film undergoes a hydration reaction in hot water (temperature greater than 80℃), producing hydrated alumina and causing the oxide film to expand (expansion rate of 33% to 100%). The expansion of the film reduces the pore size and ultimately seals it. The reaction can be represented as:

Al2O3 + H2O → 2AlO(OH) → Al2O3 •H2O

Distilled or deionized water is used for hot water, and tap water is avoided because it can lead to scaling in the pores, decreasing the transparency of the film. Ions such as Cl-, SO42+, PO43-, and Cu2+ in tap water can also hinder the sealing process due to pore blockage.

(2) Process

pH Value: 5.5 to 6 (adjusted with acetic acid).

Time: 10 to 30 minutes.

Steam Sealing

(1) Principle

Similar to hot water sealing.

(2) Characteristics

(3) Process

Pressure: 0.05 to 0.1 MPa.

Time (per film thickness): 4 to 5 minutes per micrometer.

Metal Salt Sealing

(1) Chromic Acid Sealing

Principle

Table 3: Solution Formulation and Process Conditions

| Items | Formula | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| Potassium dichromate /g.L-1 Sodium carbonate /g.L-1 Sodium hydroxide /g.L-1 PH Value Temperature/℃ Time/min | 100 18 (or 3) 6~7 90~95 2~5 | 40~55 6.5~7 90~95 20~30 | 15 4 3 6.5~7.5 90~95 2~5 |

Several Points to Note

a. Prior to the sealing treatment, it is essential to thoroughly clean the workpieces to prevent any acid from being introduced into the sealing tank. Additionally, contact between the workpieces and the tank should be avoided to prevent damage to the oxide film.

b. Impurities in the sealing solution should be controlled. When SO42+ > 0.2g/L, a suitable amount of calcium chromate (CaCrO4) precipitate can be added and filtered out, otherwise, it could lead to lightening and whitening of the sealed workpieces. When SO42+ > 0.02g/L, potassium aluminum sulfate (K2Al2(SO4)4•24H2O) can be added at 0.1~0.15g/L to prevent whitening of the sealed workpieces and a decrease in corrosion resistance. When Cl- > 1.5g/L, the sealing solution needs to be diluted or replaced; otherwise, it can cause corrosion of the oxide film on the workpieces.

(2)Salt Hydrolysis Sealing

Principle

a. The product of the hydration process (transparent substance) seals the pores.

b. Water is added for decomposition, leading to the precipitation of hydroxides within the micropores.

c. These precipitates chemically react with dye molecules to form metal-chromium complexes.

Formulation and Process Conditions of Salt Hydrolysis Sealing Solution can be found in Table

| No. | Formula | Process conditions | |||

|---|---|---|---|---|---|

| Element | Content/g.L-1 | PH Value | Temp/℃ | Time/min | |

| 1 | Nickel sulfate(NiSO4.7H2O) | 4.2 | 4.5~5.5 | 80~85 | 10~20 |

| Cobaltous sulfate(CoSO4.7H2O) | 0.7 | ||||

| Sodium acetate(CH3COONa.3H2O) | 4.8 | ||||

| Boric acid(H3BO3) | 5.3 | ||||

| 2 | Sodium acetate(CH3COONa.3H2O) | 5.5 | 4.5~5.5 | 80~85 | 10~15 |

| Cobaltous acetate (CH3COO)2Co.4H2O) | 0.1 | ||||

| Boric acid(H3BO3) | 3.5 | ||||

| 3 | Nickel acetate (CH3COO)2Ni.4H2O) | 5.5 | 5.5 | Boiling point | 30 |

| Cobaltous acetate (CH3COO)2Co.4H2O) | 1.0 | ||||

| Boric acid(H3BO3) | 8 | ||||

Free Sample

Explore Other Guide and resource

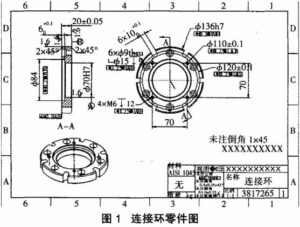

Analysis of CNC turned and milled parts

The CNC machining process arrangement of the combined turning and milling parts involves considering the processing sequence and clamping scheme to ensure the machining accuracy and dimensional tolerance of the

CNC Turining and Milling

Dive into the realm of CNC turning and milling – a cutting-edge manufacturing technology merging the capabilities of CNC lathes and milling machines. Uncover the characteristics, advantages, and diverse applications

Automatic Lathe Machining

An automatic lathe is a highly capable and precise machine that can continuously and repetitively be machining a variety of materials, including aluminum, iron, copper, zinc alloy, and plastic, among