Automatic Lathe Machining

Something you need to know about Automatic lathe machining.

What is Automatic lathe machining and how does it work?

An automatic lathe is a highly capable and precise machine that can continuously and repetitively machining a variety of materials, including aluminum, iron, copper, zinc alloy, and plastic, among others with automatic loading and feeding features. It is designed to perform continuous and repetitive processing of small-volume products in large quantities such as screws, nuts, studs, probes, contact pins, threaded rods, and other small products making it an ideal choice for the batch processing industry.It is widely used in industries such as automotive parts, refrigeration components, plumbing valves, electronic appliances, and mechanical hardware for batch processing, which can save a lot of labor.

One of the key features of an automatic lathe is its automatic feeding and feeding capabilities, which make it highly efficient and able to process large batches of parts with minimal labor. This machine is particularly well-suited for the production of automobile and motorcycle parts, refrigeration parts, water heating valves, electronic appliances, and mechanical hardware. There are several different types of automatic lathes available, including hydraulic, pneumatic, and CAM automatic lathes. Still, the automatic lathe is the most commonly used due to its high level of automation and flexibility. With its high performance, high precision, and low noise characteristics, an automatic lathe is a valuable tool for any manufacturer looking to increase their productivity and improve the quality of their products.

The basic operations of the automatic lathe include workpiece installation, tool sets, cam control, automatic feeding, and machining.

Workpiece installation: The workpiece is mounted on a chuck or collet and rotates at high speed. The spindle speed is usually between 2000-8000 RPM, depending on the material being machined. The size control accuracy can generally reach 0.005mm.

Tool setting: The tool is mounted on the turret and is moved back and forth and left and right to machine the workpiece. Typically, five turning tools are provided, and different tools are brought into the corresponding position as needed. Turning tools No. 1-5 are mainly used for turning the outer diameter, while tools No. 2, 3, and 4 are mainly used for cutting grooves, chamfers, and cutting, respectively. This machine can perform multiple processes such as threading, milling, and embossing simultaneously, without manual operation, fully automated processing, and completing all processes in one go.

Cam Control: The key control system of automatic lathes is cam control, which is used to control the automatic feeding and automatic movement of cutting tools. The movement of the cam determines the processing sequence, processing time, tool feed, and stop. One is cylindrical in shape, and after machining its end face into various shapes, the cam rotates. The other type is a circular disk shape, which is machined into the desired shape on its outer periphery, and then the rotary motion of the cam is converted into the linear motion of the tool by the transmission rod connected to the tool holder.

Automatic feeding: The equipment is equipped with an automatic feeding rack that can directly place round bar materials on it. After the equipment automatically feeds the material into the spindle clamp, it is automatically machined. After the machining is completed, the equipment will automatically stop and sound an alarm, without the need for manual monitoring and material replacement, thereby reducing labor costs and saving material replacement time.

Machining: Cam-controlled automatic lathes are equipped with five tools, with tool holders numbered 1 through 5, with each holder capable of holding 1-2 tools. Tools 1 and 5 are used for turning the outer diameter, while 2, 3, and 4 are primarily used for processes such as slotting, chamfering, and cutting.

Overall, the automatic lathe is an efficient and precise machine that provides high automation and flexibility for the production of complex parts.

What are the different types of cutting tools used in automatic lathe machining?

In addition to automatic lathe tools, it’s also important to understand the use of various tools to ensure that products do not require secondary processing. The following tools must be equipped:

Bench Drill: Used for drilling holes and tapping threads. Thread Rolling Machine: Used for external thread processing and can also complete the work of forming threads.

Grinding Machine: Used for grinding the initial lathe tools. Polishing Machine: Used for precision grinding of lathe tools, drill bits, taps, hook tools, and other cutting tools. Tabletop Lathe or Mini Lathe: Used for tasks such as chamfering and deburring.

Therefore, compared to CNC lathes, the types of cutting tools used in automatic lathes are relatively few. In daily production with automatic lathes, left drills, taps, turning tools, hook cutters, embossing (knurling) wheels, round bars, collets, and saw blades are used.

What are the different types of automatic lathe machines?

Usually, automatic lathe refers specifically to single-spindle cam-type automatic lathes. Here are four automatic lathes:

Swiss-type automatic lathe, commonly used models in China include 1104 and 1107 produced by Ningjiang Machine Tool Factory. This type of automatic lathe processes materials by feeding the material forward while keeping the tool stationary, commonly known as “Swiss-type”. Turret-type automatic lathe, commonly used models in China include MY1525, MY2025 produced by Zhangjiagang Mingyang

Precision Machinery, and BJ1525, BJ2025, BJ2225, BJ2525 produced by Changzhou Bingju Precision Machinery. This type of automatic lathe is similar to a lathe, with the material clamped in place while the tool moves back and forth along the guide rail to perform cutting, commonly known as “turret-type”.

Simple automatic lathe, divided into the long material turning and short material turning. The long material lathes feeds the material from the rear, while the short material lathes uses a vibrating disc to feed the material from the front. This type of automatic lathe is mostly produced in Zhejiang province. Miscellaneous types, have many varieties, including cam-driven, pneumatic, and a combination of pneumatic and cam-driven.

What types of products can be used with Automatic lathe machining?

Automatic lathes are suitable for products that require large-scale production. Automatic lathes have automatic feeding racks and fixtures, which can repeat machining actions continuously, thus achieving full automation of machining and greatly improving work efficiency. One-time machining reduces the time and cost of tool change. However, adjusting fixtures and automatic feeding mechanisms for small batches of parts can be cumbersome.

The workpieces suitable for automatic lathe machining need to conform to the structure of automatic sorting and feeding, for example, they can be fed through automatic feeding mechanisms such as a vibration plate, or long-axis parts are suitable for automatic feeding in a hopper. Workpieces with circular or hexagonal cross-sections are suitable for automatic machining, while those with complex shapes are not easy to machine automatically.

The material of the workpiece also needs to be suitable for automatic machining. Materials such as brass, zinc alloy, and ordinary carbon steel have good machinability and small tool wear, making them suitable for automatic lathe machining. However, materials with poor machinability such as high-speed steel and stainless steel are difficult to machine and cause severe tool wear, making them unsuitable for automatic lathe machining.

The diameter, length, and machining process of the workpiece also needs to be suitable for automatic lathe machining.

The following are some products suitable for automatic lathe machining:

Small to medium-sized metal parts, such as screws, bolts, nuts, and threaded rods.

Bushings, pins, and other cylindrical components, miniature screw copper shafts, copper inserts, motor copper sleeves, copper nozzles, and lighting globes.

Components of electronic devices, such as pins, capacitor pins, positioning pins, current pins, directional probes, probes, test probes, and high-frequency pins.

Medical device components, such as bone nails.

Automotive parts, such as axles and bearings.

Automatic turning is a highly flexible and efficient manufacturing process, making it an ideal choice for the production of small and medium-sized parts in large quantities. It can handle a variety of materials, including metals, plastics, and composite materials, and can produce parts with strict tolerances and complex geometries.

What is the difference between Automatic lathe machining and CNC lathing?

Control aspect

CNC (Computer Numerical Control) lathes use computer software to control the movement of the tool and workpiece. This machine is programmed with a set of instructions that specify the precise motion of the tool, including its position, depth, and speed. CNC lathes can be programmed to produce complex geometric shapes and profiles. CNC lathes are controlled by computer programs.

Structural differences

Different processing quantities

Different processing efficiencies

The different number of employees

Different processing costs

Different workpiece sizes

In summary, the main difference between automatic lathes and CNC lathes is the control system used to operate the machines. Automatic lathes use mechanical controls, while CNC lathes use computer software to control the machine’s movements. They differ in terms of workpiece size, production quantity, machining costs, structure, and efficiency. CNC lathes provide higher precision and flexibility in machining operations, while automatic lathes are typically used for simpler, more repetitive tasks.

What is the maximum size of the workpiece that can be machined with an Automatic lathe machining?

What is the difference between a CNC Swiss lathing (turning) and an Automatic lathe machining?

The main difference between automatic lathes and CNC Swiss lathes is the control system used to operate the machines. Automatic lathes use mechanical controls(Cam), while CNC Swiss lathes use computer software to control the machine’s motion. There are differences in the size of the workpieces, the quantity of production, the cost of processing, the structure, and the processing efficiency. The Swiss-type CNC lathe, also known as Swiss-style lathe, has a full name of spindle box moving type CNC lathe. The Swiss mode of the lathe originated in Switzerland and is internationally known as Swiss precision automatic lathe.This design enables higher precision and accuracy when machining small, complex parts with high surface finish requirements, and typically has multiple spindles and cutting tools that can work on the part simultaneously, thereby reducing cycle time.By contrast, automatic lathes are machines that use a cam to control the movement of cutting tools in a back-and-forth, left-and-right motion. They are capable of mass-producing medium-sized parts but are not as precise as CNC Swiss lathes. Automatic lathes also typically have a limited number of spindles and tools, which can limit their versatility in machining more complex parts.

The differences between CNC Swiss lathing (turning) and an Automatic lathe machining are as follows:

Equipment Price

Automatic lathes are cheaper, costing about 9000 USD, while Swiss Lathes are expensive, usually costing over 43000 USD.

Product Unit Price

In the machining industry, the determination of the product unit price usually takes into account the price and efficiency of the machining equipment. Automatic lathes are cheaper and have high machining efficiency, so the price of the machined parts is relatively lower. Swiss Lathe, on the other hand, is very expensive, so the products they machine typically choose high value-added, high-priced, and high-quality products.

Mechanic's Requirements

In the automatic lathe machining process, cams are used to control the cutting tool or fixture to machine the product. Adjusting the product size and controlling the product accuracy requires long-term and skilled operation experience of the mechanic, without the need for programming skills. In contrast, CNC Swiss lathes are CNC computer-controlled equipment, which requires higher technical skills from the mechanic. Mechanics need to have rich operating experience, CNC programming skills, and a deep understanding of the equipment to successfully operate CNC Swiss Lathes.

Number of Tool Holders

Control System

Automatic Lathes generally use cams to control the motion of the cutting tool, while CNC Swiss Lathes generally use CNC computer control systems to control the motion of the cutting tool.

Axis

The cutting tools of Automatic Lathes can only move forwards, backward, left, and right to machine products, making it impossible to machine complex multi-sided products. CNC Swiss Lathes generally have 3-axis, 4-axis, and 5-axis, and can machine complex and irregular surfaces by rotating different axes such as X, Y, Z, A, and B.

In summary, although both CNC Swiss lathes and automatic lathes are used for turning, CNC Swiss lathes are more precise, versatile, and better suited for machining complex parts with high surface finish requirements. In contrast, automatic lathes are more suitable for mass-producing simple parts.

Free Sample

Explore Other Guide and resource

12 Automatic Lathe Manufacturers in china in 2024

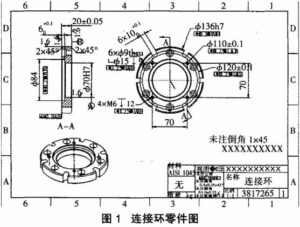

The CNC machining process arrangement of the combined turning and milling parts involves considering the processing sequence and clamping scheme to ensure the machining accuracy and dimensional tolerance of the

Analysis of CNC turned and milled parts

The CNC machining process arrangement of the combined turning and milling parts involves considering the processing sequence and clamping scheme to ensure the machining accuracy and dimensional tolerance of the

CNC Turning Services 101 – Know the Every Unknown

Get a detailed overview of CNC turning services. Explore the benefits, types, and materials involved in creating high-precision parts for various industries.