CNC Milling Parts

CNC Milling Parts

CNC Milling parts manufacturer in China.

MOQ Starts from 1pcs.

As a specialized CNC milling parts manufacturer, Masion provides high-quality custom different CNC milling parts services to customers with outstanding production advantages, advanced technological capabilities, and professional solution offerings.

Masion Capability

High Capacity, Proper Price

10000pcs production capacity per month make the price lower.

Free Samples, Low MOQ

1pcs MOQ make you order flexibly with one free sample for you testing.

Certified Factory, Guaranteed Quality

ISO9001:2008 and strictly 100% inspection guarantee quality and CMM inspection equipment.

High precision, thick gold

With 0.005mm tolerance and with different surface finishing and different materials.

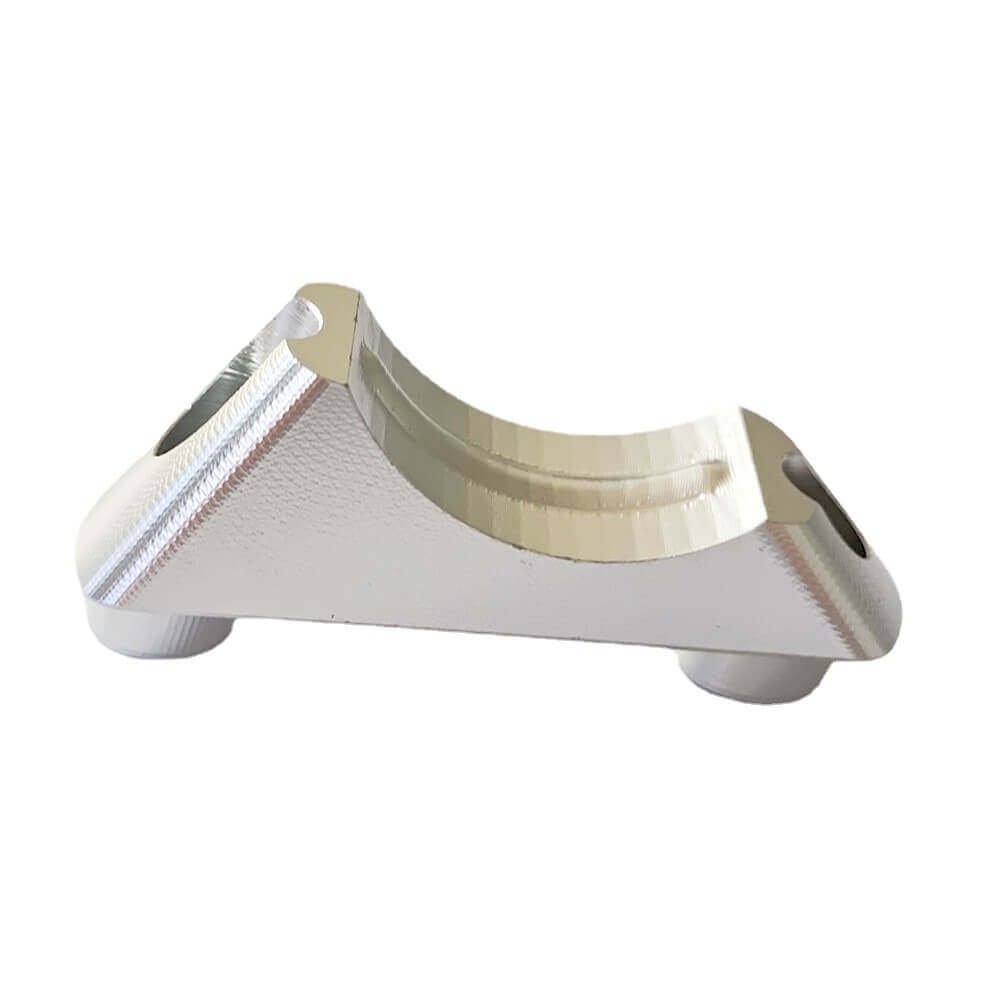

Our Products

What Sets Us Apart

Strong Experience

With 16 years of cnc milling parts machining expertise, we focus on high-quality, customized solutions for different cnc milling parts demands.

Advanced Machine

30 sets precision 3,4,5 axis CNC machining center with mature and stable manufacturing processes with technical machinist and engineer.

Surprised Price

Stockpiling a large amount of conventional materials and having a mature production process can reduce the overall price by 5%.

24/7 Engineering Support

Masion specializes in offering 24/7 engineering support, design services, cost reduction, quality assurance, smooth product transition sun paralleled excellence, etc.

CNC milling parts Manufacturing Process

Raw Material

In the preparation stage of various materials such as stainless steel, titanium, aluminum, PEEK, POM, etc, it is typically required that the materials conform to specified model requirements and meet standard performance criteria. Additionally, we maintain a regular inventory of product materials to address any issues related to insufficient delivery time.

CNC milling parts Machining

- Milling

- Drilling

- Threading

- Cutting

- Countersinking

- Boring

- Tapping

- Reaming

Packing

- For CNC milling parts. with extremely high requirements, we pack the part one by one with PC bag, or blister bag etc.

- For CNC milling parts. with moderate requirements, we also perform packing the bag as clients need.

- For CNC milling parts. with no packaging requirements, we will arrange the products neatly and separate them with cardboard.

Quality Control(Testing)

- Masion conduct material inspections to ensure the parts correctness.

- Masion perform initial inspections on the first samples; production proceeds only if the dimensional inspection is passed, with adjustments made if necessary for non-compliance.

- Masion conduct sample inspections on the manufactured products to ensure compliance with the dimensional requirements specified in the drawings.

Application Area

CNC Milling Parts FAQs

In simple terms, CNC milling parts refer to securing a workpiece on the worktable and programming a CNC machining center (such as three-axis, four-axis, five-axis, or six-axis) or milling machine. Subsequently, utilizing an automatic tool-changing system to select and replace different tools from the tool library, the tools rotate while executing various machining operations such as milling, drilling, tapping, slotting, etc., by moving along the X, Y, Z, A, B, and other axes. The final product obtained after these machining processes is known as CNC milling parts.

Metals:

Aluminum: Popular due to its lightweight, good strength-to-weight ratio, and ease of machining. It’s widely used in aerospace, automotive, and consumer goods.

Steel: Known for its strength and durability, steel is used in applications requiring high toughness. Variants like stainless steel are used for corrosion resistance.

Brass: Often chosen for its aesthetic appeal and ease of machining, brass is used in decorative items, electrical components, and musical instruments.

Titanium: Highly valued in aerospace and medical industries for its strength, lightweight, and corrosion resistance.

Plastics:

ABS: A common thermoplastic with good mechanical properties, suitable for functional prototypes and consumer goods.

Polycarbonate: Known for its strength and transparency, it’s used in automotive, aerospace, and consumer products.

Nylon: Durable and wear-resistant, nylon is used in mechanical components like gears and bearings.

POM (Acetal): Characterized by its low friction and high dimensional stability, POM is used in precision parts for mechanical applications.

Composites:

Carbon Fiber Reinforced Plastics (CFRP): Used in applications where high strength-to-weight ratio is crucial, like in aerospace and sporting goods.

Fiberglass: Offers strength and is less expensive than carbon fiber, used in automotive and marine applications.

Wood and Wood Composites:

Hardwoods and Softwoods: Used for decorative purposes, custom furniture, and architectural models.

MDF (Medium-Density Fiberboard): Common in furniture and cabinetry for its smooth finish and consistency.

Others:

Foam: Used for prototypes and architectural models due to its ease of machining.

Graphite: Utilized in high-temperature applications and for electrical conductivity.

The production time for CNC milling parts in CNC machining factories is not fixed; it is determined by many factors. There are many CNC machining factories, and the production cycle for the same product can vary. If a CNC machining factory has fewer machines, lacks proper management mechanisms, and the staff is not efficient, the production cycle will naturally increase. Masion has dozens of machining equipment, a well-established management system (e.g., ISO quality management system), and operates efficiently, leading to faster delivery times. Of course, the production cycle also depends on factors such as the complexity of the parts and the coordination of involved processes. Generally, for 1-10 pieces, delivery takes 3-5 days, and for 10-500 pieces, delivery takes 7-20 days. Therefore, contact us promptly, and we will help you determine the fastest production cycle.

Production Control Dimensions:

The tool’s cutting and retracting routes should follow the tangent direction of the part’s wheel.

Generally, rough machining adopts climb milling, and finish machining adopts conventional milling.

Convert the dimensional tolerances on the part drawing into symmetric distribution forms.

The feed speed of the tool at corners should be reduced.

When machining holes with high positional accuracy requirements, the positioning direction of the machining route should be maintained.

Use the optimal CNC machining program to ensure the surface quality of the workpiece.

Clamp the workpiece reasonably to reduce workpiece deformation.

Inspection Control Dimensions:

First-piece inspection.

In-process inspection.

Random sampling inspection of finished parts.

100% full inspection of some critical dimensions.

Here is the translation of the factors influencing the cost of CNC milling parts:

Processing Material: The type and amount of material used directly determine the cost of processing.

Processing Difficulty: The greater the difficulty of processing, the higher the cost.

Mold Manufacturing: For some parts with complex shapes, mold manufacturing is required, which also increases the processing cost.

Processing Technology: Different processing technologies will lead to different costs.

Processing Precision: The higher the precision requirement, the greater the processing difficulty, and consequently, the higher the cost.

Free Sample

Explore Other Products

Sheet Metal Fabrication

New Energy Battery Casing and other differentSheet Metal Fabrication parts such as Housing, Case,Enclosure, etc.

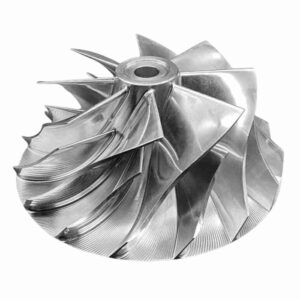

Aluminum Boat Impeller

Five-axis simultaneous complex parts machining, aluminum boat impeller, watercraft impeller, compressor impeller, turbocharger impeller,and another different 5-axis CNC parts etc.

CNC Milling

CNC Milling Aluminum different automobile hub, and different 3-axis, 4-axis,5 axis CNC machining parts.