Selective Laser Sintering

Selective Laser Sintering

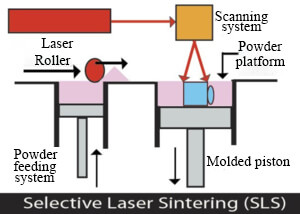

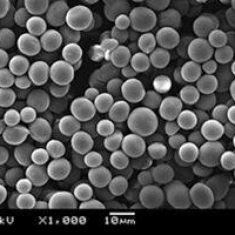

Similar to the SLA photopolymerization process (resin printing), SLS also utilizes laser curing of the entire substance. The difference lies in the use of infrared laser beams in SLS, and the material shifts from photosensitive resin to composite materials like plastics, wax, ceramics, metal powder, or nylon powder. Initially, a very thin (sub-millimeter) layer of raw powder material is not spread on the worktable. It is then scanned by a computer-controlled laser beam through a 3D scanner at a specific speed and energy density to layer the two-dimensional data. The laser-scanned powder is sintered into a solid layer of a certain thickness, while the unscanned areas remain as loosely packed powder.

SLS Technology Schematic

Working Principle:

The powder is preheated to a temperature slightly below its melting point, then leveled using a roller or scraper. Under computer control, a high-intensity CO2 laser selectively sinters parts based on layered cross-sectional information. The sintered material adheres to the formed part below, and the process repeats layer by layer. Once all the sintering is complete, excess powder can be removed, leaving the sintered portion.

Pros and Cons

Advantages

- Suitable for complex structures and unique geometries, nylon 3D printing supports small-batch/customized production.

- Excellent material strength without the need for added processing supports.

- Short processing cycles, low costs.

- Optimized structures and open-minded thinking.

Disadvantages

- Surface quality not as high as SLA resin 3D printing.

- Available materials are temporarily limited by industry applications.

Optional Materials

PA2200 Nylon Material

- Performance: Excellent strength, can undergo secondary processing and assembly, white appearance

- Typical Applications: 3D printed external display components, casings.

PA3200 Nylon Glass Fiber Material

- Performance: High strength, can undergo secondary processing and assembly, white appearance

- Typical Applications: 3D printed external display components, casings.

Application Scope

- Validate functional tests, such as prototypes for appearance or R&D design.

- Small-batch customization/personalization, including 3D printing for custom gifts.

- Suitable for industries requiring precision and complex structures, such as aerospace, medical, molds, and 3D printing surgical guides.

Explore Other Products

CNC Milling

CNC Milling Aluminum different automobile hub, and different 3-axis, 4-axis,5 axis CNC machining parts.

Swiss CNC Machining

Custom Swiss CNC turningTC4 titanium alloy Anodizingmedical dental nail bone nail.

3D pringting

Masionprovides a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering), MJF (Multi Jet Fusion), and DLMS (Direct Metal Laser Sintering).