Table of Contents

Swiss Machining – Know the Every Unknown

No one can ignore the value of the swiss machining in dynamic industries. Efficiency as well as level of precision in comparison to other methods play a key role in this regard. It has become a go to solution for the industries requiring unmatchable accuracy in components. Right and effective knowledge in Swiss precision machining can assist businesses as well as individuals. This way they can improve effectivness of operations and avoid material and time wastage. The aim of this guide it to help you with knowledge on swiss precision machining processes, applications, tools, materials, and much more. Let’s get started to uncover facts!

Historical background

Swiss screw machining rises as an incredible solution to watch industries in the year 1870. Jakob Schweizer in creating fine parts for watches developed a lathe featuring moving headstock. His efforts clearley reflects that why the world renowned watch maker company Rolex has its foundations in Switzerland. After the development of lathe the Schweizer idea widespread around the globe just within a decade. In todays age the look and physical appearance of the swiss machine is far beyond than what they seem earlier one and a half century ago. Both in the efficiency and effectiveness Swiss machining surpasses the older machine although with same objective to develop thinner, and intricate components.

What is Swiss Machining?

Another name of the Swiss cnc Machining is Swiss screw machining or swiss turning. You can define it as a process which help you manufacture complex, smaller parts without compromising precision and accuracy. Using this process you can make parts with incredible tight tolerances. The Swiss type cnc machining is completely different from the standard lathes. In swiss machines the tool stay stationary while component moves and vice versa in lathes. With Swiss cnc machining you can create pins, screws, medical components, etc.Main Components and Their Functions That Make Up CNC Swiss Machining

Sliding Headstock

The workpiece is clamped in the sliding headstock and is transported to and fro through the guide bushing. This motion allows the workpiece to machined closer to the cutting tools, which gives greater stability and accuracy.Guide Bushing

The guide bushing holds the part secure as it passes through the machine, eliminating deflection and maintaining accuracy, particularly for longer, thinner parts.Cutting Tools

Shapes the workpiece with various cutting tools like turning, milling and drilling tools. They can run concurrently improving efficiency.

Tooling Plates

Cutting tools are held in place by tooling plates. These plates are highly customizable in CNC Swiss machines for different tool setups.CNC Controller

The brain of the machine is the CNC controller, which guides the entire single operation with extreme precision. It takes over the movements of the headstock, cutting tools, and guide bushing.6. Collets

To clamp the work piece securely while it’s being machined, collets are employed. This tightens the grip and helps to maintain the part stable during the process.Chip Conveyor

Metal shavings (called chips) produced during machining are removed by the chip conveyor. This allows you to keep the workspace clean and the workpiece from getting damaged.Coolant System

The coolant system circulates liquid around the cutting tools and workpiece to keep them from overheating and producing a smooth finish.Spindle

It spins the workpiece and drives the headstock. In Swiss machining it is often synchronized with the guide bushing for best control.Sub-Spindle

Secondary operations, such as additional milling or drilling, are often performed on a sub-spindle that is mounted on the main spindle without removing the workpiece from the machine.Bar Feeder

Raw material (in bar form) is given to the machine by the bar feeder, so the machine can run continuously without the need for manual intervention.Tailstock (Optional)

The long parts are supported by the tailstock, which also helps reduce deflection while machining.How Swiss Lathe Machining Works

Swiss lathe machining consists of a series of steps operated under careful control. Here’s a step-by-step explanation:- Loading the Workpiece: The bar feeder passes a bar of raw material into the machine and stops the collets in the headstock.

- Guide Bushing Support: Guide bushing allows the workpiece to pass through, stability and deflection especially for long parts.

- Cutting Operations: Moving the workpiece, several different kinds of cutting tools varying from lathe (or turning), milling and drilling tools shape the part. These tools work at once and time is saved.

- Sub-Spindle Operations: The workpiece is then transferred to the sub spindle should the machining require additional cuts or drills but the part will not be removed from the machine.

- Chip Removal: The chip conveyor removes chips generated from cutting from the machine keeping it clean and accurate.

- Cooling: The coolant system throughout the process keeps the tools and the work piece at the best temperature to avoid distortion or damage.

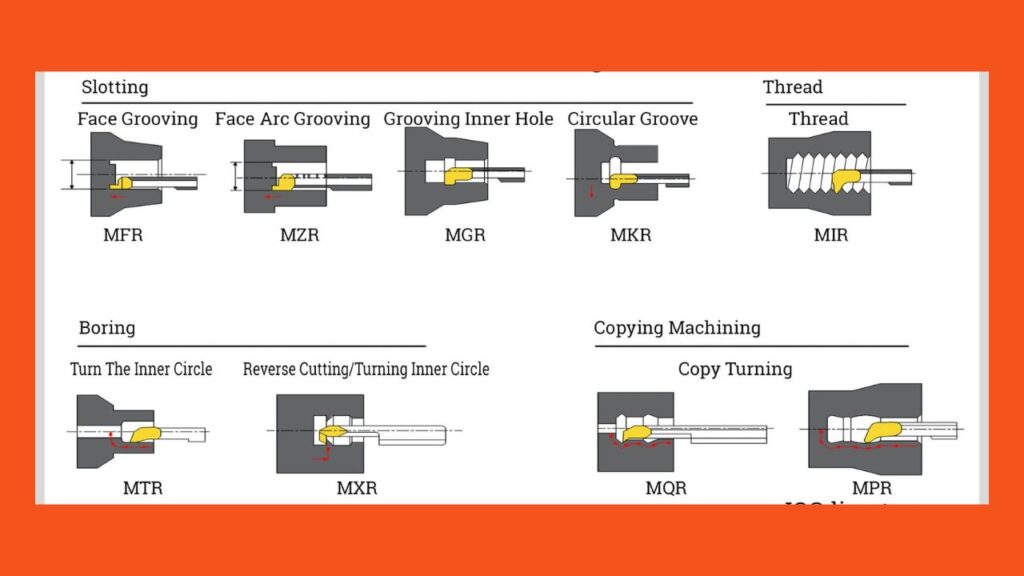

Common Swiss Machining Operations

1. Turning

Turning cuts away the outer layer of the workpiece to reveal cylindrical forms. This operation plays a key role and falls into a fundamental category of Swiss turning machining.2. Milling

Complex elements such as slots or grooves are created through the milling process. The workpiece can be turned while Swiss machines handle milling tasks simultaneously.3. Drilling

Swiss machining drilling offers high accuracy and precision for making tiny and precise holes in the workpiece.

4. Threading

Creating internal or external thread shapes is part of the threading process. Swiss machines effectively perform both types of threading with superior accuracy.5. Boring

Boring widens an existing hole to reach a specified diameter. This technique is utilized whenever there is a need for detailed precision on a specific hole size.Common Tools Used in Swiss Machining

Several specialized tools make Swiss screw machining possible:1. Guide Bushings

Guide bushings keep the workpiece in place while it traverses the machine to minimize deflection.2. Cutting Inserts

These inserts are designed to conduct specific cutting tasks such as turning milling and boring which delivers a sharp and accurate cut.3. Collets

The collets securely hold the workpiece so it remains stable and precise throughout machining operations.4. End Mills

End mills complete milling tasks to customize the workpiece. They vary in size and form based on the challenge at hand.5. Threading Tools

Tools that create threads are utilized to form threads on the workpiece being internally or externally threaded.6. Reamers

Reamers ensure an immaculate appearance on the openings by providing them with the necessary dimensions and surface standards.Swiss Precision Machining – Top Perks

Exceptional Precision

This approach ensures precise dimensions for accurate parts required in fields like medical technology or aviation.Capable of processing intricate parts.

This method stands out in manufacturing detailed components that feature complex shapes. This approach excels at creating small details and intricate pieces such as screws and pins.High Efficiency and Speed

Swiss machines operate on their own to increase production speed and reduce human oversight. This enhances productivity and minimizes errors caused by humans.

Simultaneous Tooling

A Swiss machine can use several cutting tools at the same time to decrease cycle times and enhance efficiency.Low Material Waste

Swiss turning machining’s precision decreases material waste in highly valued materials.Swiss Machining Types

Swiss type cnc machining exists in multiple forms based on the tools and methods employed. Traditional Swiss machining depends on operator control. Modern equipment utilizes CNC for better accuracy and automation.| Sr. No. | Type | Features | Applications | Purpose |

| 1 | Traditional Swiss Machining | Manual operation, sliding headstock, guide bushing, limited automation | Small, intricate parts like watch components, medical devices, and precision screws | High precision, tight tolerances, small-scale production |

| 2 | CNC Swiss Machining | Computer-controlled, automated operations, increased efficiency, wider range of part complexity | Medical devices, automotive components, aerospace parts, and electronics | High-volume production, complex geometries, reduced labor costs |

| 3 | Multi-Spindle Swiss Machining | Multiple spindles for simultaneous operations, increased productivity | Automotive parts, electronics, and medical devices | Faster production, reduced cycle times, complex parts with multiple features |

| 4 | Swiss-Type Milling | Milling operations on Swiss machines, expanded capabilities | Complex geometries, intricate features, and multi-axis machining | Increased versatility, combined turning and milling operations |

| 5 | Swiss-Type Turning | Traditional turning operations on Swiss machines | Cylindrical parts, shafts, and threaded components | Precision turning with tight tolerances |

Swiss Machining Applications

Aerospace

Swiss machining’s expertise is utilized in the aerospace field to manufacture parts that require minimal tolerances.Medical Devices

There are various components that employs the swiss lathe machining applications. These includes the surgical implants as well as other equipments. Specially those which require fine machining and where tolerance is undeniable.Automotive

In automotive sector the swiss machining play a key role. This is true for the making of intricate and smaller components.

Electronics

In the electronics field, Swiss lathe machining is used to build small and fine parts such as connectors and switches using an unmatched level of precision.Notable Differences For Swiss and CNC Machining

Precision and Tolerance

It is for these reasons that Swiss screw machining has gained its fame and reputation for creating tight tolerances on small diameter precision parts. As for the accuracy, CNC machining can provide a reasonable level; however, it will not necessarily allow reaching the accuracy level of Swiss machining for such small and thin parts.Design and Operation

The other hand they have the moving headstock with the guide bushing to support their drill but they are good for long and slender parts. A fixed workpiece for the part is used in traditional CNC systems, and the system works well for long and detailed parts.

Production Speed

versus mass production of micro parts, high output rates are best achieved with Swiss precision machining, poor for large robust parts. On the other hand, it could perform in tool causes in parallel in a few cases and will have greater rate in such operations than CNC milling.Setup and Automation

Manufacturing in Swiss machining may not require the physical touch at times hence allowing continuous operations with minimal human interference. Some advanced CNC systems may come with automation though CNC machining usually requires some amount of manual configuring.What Materials Are Used in Swiss Machining?

Swiss machining is compatible with a wide range of materials, including:- Brass: Used extensively in various electronics and machinery.

- Copper: Suitable for creating electrical devices because of the high conductivity it provides.

- Carbon Steel: Versatile and robust frequently employed in car and manufacturing sectors.

- Stainless Steel: It has applications in healthcare and food manufacturing thanks to its corrosion resistance.

- Tool Steel: Crafted to produce cutting tools and dies.

- Aluminum: Best suited for automotive and aerospace industries because of activities such equals sign committee and easy to machine material.

- Titanium: In medicine and aviation, for example, it will apply due to its hardness and bio-compatibility.

- Nickel: Utilised in aerospace and electronics industries due to its important characteristics of high resistance against corrosion and high working temperatures.

- Plastics (e.g., Nylon, Delrin): This is commonly used in apparatus used in medical facilities, as well as in home electrical appliances.

Limitations of Swiss Machining

- Higher Setup Costs: Initial setup of the machine may actually prove to be costly due to the complexity of the architecture.

- Material Limitations: Swiss machines are particularly useful for decreasing sizes of parts and prove to be less effective for large parts.

- Heat Dissipation Challenges: Some of the concerns that have to be addressed include controlling heat since excessive heat reduces the quality of parts made from metals.

Conclusion

Swiss machining in short play a vital role in facilitating the operations of multiple devices. It assists in the formation and completion of the set objectives by the various industries. By employing this technology individuals as well as businesses can boost their efficacy, operations as well as productivity. The above guide has provided you with the sufficient knowledge. By following it, you can practically work with the Swiss turning machining. You can reduce the overall downtime while boosting the net roi of your business.Explore Other Guide and Resource

CNC Machining

CNC Machine Shop

Masion is a CNC machine shop to manufacture different CNC machining parts you could learn CNC machine shop here clearly.

December 6, 2023

CNC Machining

Swiss Turn Machining

Swiss Turn machining is one of the most common modern machining techniques. Its advantages of speed, convenience, and high precision make it highly favored by customers, leading to its widespread

December 6, 2023

CNC Machining

Considerations for CNC machining production

Explore the intricacies of CNC machining production with a focus on hole machining and boring processes. Delve into considerations, safety measures, and practical tips for effective CNC operations. This guide

December 6, 2023