Rapid Prototyping Manufacturing Services

Rapid Prototyping Manufacturing Services

China Rapid Prototyping Manufacturing Services-Your Trusted CNC and 3D Rapid Prototyping Manufacturer.

I understand that you are looking for a suitable manufacturer for rapid prototyping (3D printing, rapid CNC machining, rapid sheet metal fabrication, etc.), and Masion can meet your requirements for rapid prototyping product production.We specialize in customizing rapid prototyping products for various industries such as medical, aerospace, automotive, electronics, telecommunications, refrigeration, optics, home appliances, and more.We have advanced 5-axis machining equipment and a team of professional and skilled designers, engineers, and machinists who can address the technical challenges of your complex products.

What we do

Our rapid prototyping services

Fast 3D printing

3D printing (3DP), also known as additive manufacturing [1], is a technology that uses digital model files as a foundation and employs adhesive materials such as powdered metals or plastics to construct objects through a layer-by-layer stacking process. It offers design freedom, enables low-volume production, reduces production time, and saves costs, making it suitable for early-stage product validation in projects.

Among the 3D printing techniques, Layered Object Manufacturing (LOM), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA) are the most mature in terms of technology.

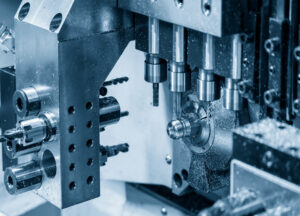

Rapid CNC Prototype Machining

CNC prototype machining is a process technology that utilizes equipment such as lathes, milling machines, machining centers, etc., to perform multiple operations such as milling, drilling, boring, tapping, and threading. CNC machining offers high precision, low surface roughness, and excellent glossiness.

Materials we can machine include:

- Plastics: ABS, PC, acrylic, PMMA, nylon PA, POM, PP, etc.

- Metal materials: aluminum alloy, stainless steel, iron, copper, titanium alloy, etc.

Sheet metal fabrication is a comprehensive cold working process for thin metal sheets, including cutting, punching, bending, rolling, welding, riveting, forming, and surface treatment. It can be produced without the need for molds, using processes such as CNC punching, laser cutting, shearing, bending, and riveting machines. Sheet metal fabrication is typically used for prototype production or small batch production, and it can be costlier. It offers short processing cycles and quick turnaround times.

Rapid Injection Molding Tooling

Rapid tooling, also known as prototype tooling or soft tooling, is essentially an injection molding tool that enables the quick and cost-effective production of large quantities of parts. It is chosen only when there is a 90% certainty of success in product development projects. The primary purpose of manufacturing rapid tooling is to test and validate components during the prototype development stage of new product development.

Where to use

Metal prototype models

Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Stainless Steel, Copper, Iron, Sheet Metal

Ransportation vehicle models

Lighting and decorative lighting models

Various lighting and decorative products such as LED daylight lamps, bulb lights, street lights, etc

Machinery industry equipment

Machine parts, electronic instruments, various mechanical components for medical devices, and industrial equipment.

Household appliance model

Household appliances such as televisions, displays, air conditioners, vacuum cleaners, humidifiers, etc

Surface Finishes

Surface treatments such as oxidation, baking paint, silk-screen printing, electroplating, laser engraving, brushing, etching, and more

Why Choose Us

Rich Experience

With years of experience in prototype manufacturing, our prototype production process is stable and ensures rapid turnover of products, mitigating issues during the prototyping phase and ensuring consistent production.

One-stop Service

We offer a comprehensive one-stop service encompassing prototype design, production processing, surface treatment, small-batch production, and large-scale production. We provide various processing services including 3D printing, sheet metal fabrication, rapid CNC prototyping, and prototype tooling machining, among others.

Technological Innovation

Complex and highly challenging curved and functional structural prototype models can be rapidly created while maintaining precise originality.

Machining Speed

Short production lead times, fast delivery, ensuring on-time delivery as per the agreed schedule

Machining precision

High precision, tolerance up to 0.01mm

Quality control

The company boasts industry-leading processing capabilities, an experienced technical team, and assured material quality.

Advanced Machine

Advanced prototype manufacturing and processing equipment, along with professional and mature support facilities, ensure high precision during the prototype production process, meeting the requirements of the drawings

Lower Price

High cost-effectiveness – for prototypes of the same level, our prices are more affordable.

Mass Production

Top domestic mold team, precision steel molds capable of producing up to 700,000 cycles

High Product Yield

By combining 3D printing with post-processing, we have reduced the prototype validation cycle from one month to just two days.

Expert Team

A professional technical team with skilled engineers, technicians, and mechanics, each with clear responsibilities, ensures a smooth, efficient, and precise custom prototype manufacturing process. We also have a specialized team for bulk coloring, enhancing overall production efficiency

Quality System

An integrated technical support system with quality inspection standards and quality control processes to ensure that prototype quality meets the drawing specifications

Products materials CNC prototype Rapid Machining

| Aluminum Alloy | Al 6061 | Al 5052 | Al 2A12 | Al 7075 | - | - | - | - |

|---|---|---|---|---|---|---|---|---|

| Stainless Steel | SS 303 | SS 304 | SS 316 | SS 316L | SS l420 | SS 430 | SS-17-4PH | SS 301 |

| SS 321 | - | - | - | - | - | - | - | |

| Alloy Steel | Q235(A3 Steel) | Steel #45 | Cr12 | 3Cr13 | GCr15 | 40Cr | spring steels -65Mn | die steel -SKD11 |

| Copper Alloy | Brass-H59 | Brass-H62 | Copper-T2 | oxygen-free copper TU2 | tin bronze -QSn-6-6-3 | BeCu(beryllium copper) -C17200 | - | - |

| Other alloys | electrical pure iron -DT4C | electrical pure iron -DT4E | titanium alloy -TC4 | magnesium -AZ91D | - | - | - | - |

| Plastic | -ABS | -PTFE | -POM | Bakelite | -PMMA | -PP | -PPS | -PU |

| -PVC | FR4 | -HDPE | -LDPE | -PA6 | -PA66 | -PC | -PEEK | |

| Special materials and others | carbon fiber plate | Graphite | - | - | - | - | - | - |

Silica GelMold Materials

| -ABS | -PTFE | -POM | Bakelite | -PMMA | -PP | -PPS | -PU |

| -PVC | FR4 | -HDPE | -LDPE | Nylon-PA6 | Nylon -PA66 | -PC | PEEK |

| NBR | - | - | - | - | - | - | - |

3D printing

| Material name | Color | Printing Process | Delivery | Characteristics |

|---|---|---|---|---|

| Imported photosensitive resin | White | SLA | 24H | High precision, fine surface, not only for appearance parts, but also for structure, assembly and function verification |

| Translucent photosensitive resin | Semitransparent | SLA | 48H | Smooth surface with strong detailed performance, excellent water resistance and dimensional stability |

| Transparent photosensitive resin | Completely Transparent | SLA | 72H | The product has high permeability, crystal clear color, high brightness and low water absorption |

| High temperature (70℃) photosensitive resin | Yellowish | SLA | 24H | Excellent high temperature resistance. Suitable for some high temperature requirements of the prototyping sample |

| High temperature (100℃) photosensitive resin | Beige | SLA | 48H | Excellent high temperature resistance. Suitable for some high temperature requirements of the prototyping sample |

| High toughness photosensitive resin | Kelly | SLA | 48H | High material strength, excellent toughness, fine surface texture; suitable for both aesthetic and structural components. |

Rapid Sheet Metal Fabrication materials

| Aluminum Alloy | Al 1060 | Al 5052 | - | - | - |

|---|---|---|---|---|---|

| Stainless Steel | SS-201 | SS-304 | - | - | - |

| alloy steel | -SPCC | -SECC | -SGCC | Q235-(A3) | #45 |

| Brass Alloy | Brass-H59 | Brass-H62 | Copper-T2 | - | - |

Free Sample

Explore Other Services

CNC Turning Services

https://youtu.be/TfLpTK81Lw0 As a professional CNC turning manufacturer, supplier, and factory, Masionis dedicated to delivering high-precision CNC turning parts with a strong focus on cost-effectiveness. With our advanced CNC lathes, we

Automatic Machining

Automatic lathe machining Services – Precision Automatic lathe machining (turning) Parts Manufacturer & Supplier with 20 sets Automatic lathe machining Machine. Automatic Lathe Machining Services We are a professional manufacturer,

CNC Milling and Turning Services

CNC Milling and Turning Services –China CNC Turning Milling Parts Manufacturer. CNC milling and turning is one of the advanced manufacturing technologies in the international mechanical processing industry. It integrates