ABS CNC Machining

ABS CNC Machining

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer known for its excellent balance of material properties. It exhibits good toughness and chemical resistance, along with a range of other customizable characteristics depending on the additives included in the plastic formulation. ABS sheets are a common type of plastic material known for their excellent mechanical performance, wear resistance, chemical corrosion resistance, and high-temperature resistance. ABS sheets find widespread applications in various industries, including household appliances, automotive, electronics, construction, and are highly favored for their ease of processing, molding, and coloring.

Surface Finishes after ABS CNC Machining

| Picture | Surface finishes | Machining principle | Machining material | Colors | Texture | More |

|---|---|---|---|---|---|---|

| Bead Blasting | Using stainless steel grit and high-speed air blasting, you can achieve a matte finish on the surface of ABS, providing it with a frosted appearance. | white corundum grit,ABS | Haze | Matte | Learn More |

| ABS Polishing | By using abrasive paper and a polishing machine to polish and buff ABS, its surface can be made glossy. | abrasive paper, ABS | N/A | Glossy | Learn More |

| ABS chrome plating | To create a protective chromium layer on the surface of ABS through immersion in chromic acid, it is necessary to first form a copper protective film on the ABS surface before proceeding with chromium plating, followed by nickel plating. | Chromic acid, ABS | Silver(chrome color) | Glossy | Learn More |

| ABS PVD plating | In a vacuum environment, a thin film is formed on the surface of ABS using either a distillation or sputtering method. To ensure that the ABS surface is free of bubbles, pores, and remains smooth and glossy, it is necessary to apply a primer before the coating process. | PVD coating, Titanium nitride, titanium carbide, Alumina, silicon nitride | Black, blue, light blue, royal blue, purple, red, green, dark gold, light gold, bronze, gray, black, gray black, rainbow colors gun's color, coffee color, etc. | Glossy, semi-glossy, matte | Learn More |

| ABS Golden plating | Using the water plating method (in a chemical electroplating solution), apply a thin layer of gold to the surface of ABS to ensure its smooth and glossy appearance. | Silver nitrate, chemical nickel, gold powder,etc | Golden | Glossy | Learn More |

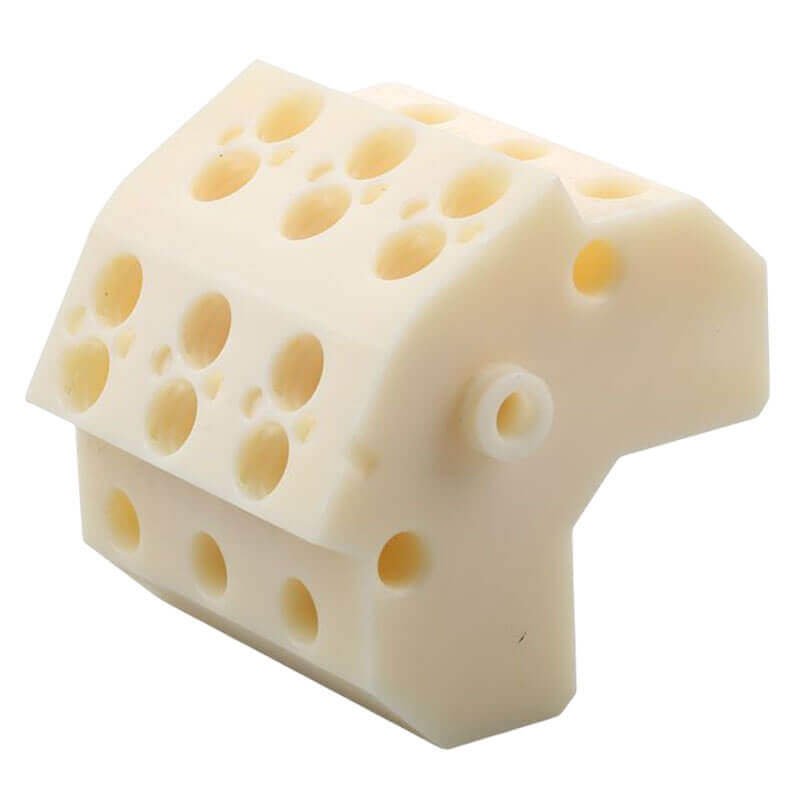

Some Picture ABS CNC machining Parts

ABS CNC Machining FAQs

Unlike ABS injection molding, ABS CNC machining utilizes equipment such as CNC machining centers, CNC lathes, CNC laser cutting machines, and others to perform a series of machining operations on ABS, including turning, milling, laser cutting, drilling, tapping, and more. This allows for the production of complex shapes that conform to the design specifications without the need for molds.

Free Sample

Explore More Plastic Materials

CNC Machining Bronze

There are many types of bronze, with commonly used ones including phosphor bronze, tin bronze, and aluminum bronze. Additionally, there are less commonly used types like beryllium bronze, silicon bronze,

Brass CNC machining

Brass is a material widely used in various fields. It is an alloy composed of brass and base metal (such as zinc, previously tin). It typically exhibits color and is

PEEK CNC machining

Polyetheretherketone (PEEK) is a special type of high-performance polymer material known for its high mechanical strength, resistance to high temperatures, impact resistance, flame retardancy, acid and alkali resistance, hydrolysis resistance,