CNC PMMA Machining

CNC PMMA Machining

PMMA is a material with high mechanical strength, strong dimensional stability, and excellent resistance to creep. PMMA sheet is a high-performance acrylic glass widely used in applications such as construction, furniture, interior decoration, advertising signs, lightboxes, display cabinets, and more. CNC machining is an efficient, precise, and controllable method that can create various shapes from PMMA sheets.

Surface Finishes after PMMA CNC machining

| Picture | Surface finishes | Machining principle | Material | Colors | Texture | More |

|---|---|---|---|---|---|---|

| Bead blasting | Bead blasting acrylic is created by spraying substances like aluminum oxide onto the surface of acrylic sheets to achieve a certain level of matte texture. Bead blasting acrylic surfaces exhibit a matte texture while maintaining high transparency and resistance to scratching. It is commonly used in the production of items such as seats and furniture. | Silicon carbide, glass sand, alumina | N/A | Matte | Learn More |

| Polishing | After polishing, acrylic exhibits a highly reflective mirror-like surface texture. Mirror acrylic is characterized by high transparency, high reflectivity, and a smooth surface, making it commonly used in the production of decorative items and display cases | #1200 to #2000 sandpaper | Transparant | Glossy | Learn More |

| Paint spraying | Utilize appropriate spray techniques, such as spray pressure, spray distance, and spray angle. Ensure even coating and prevent dripping or accumulation | Water-based acrylic paint,Solvent-based acrylic paint | Different colors | Glossy | Learn More |

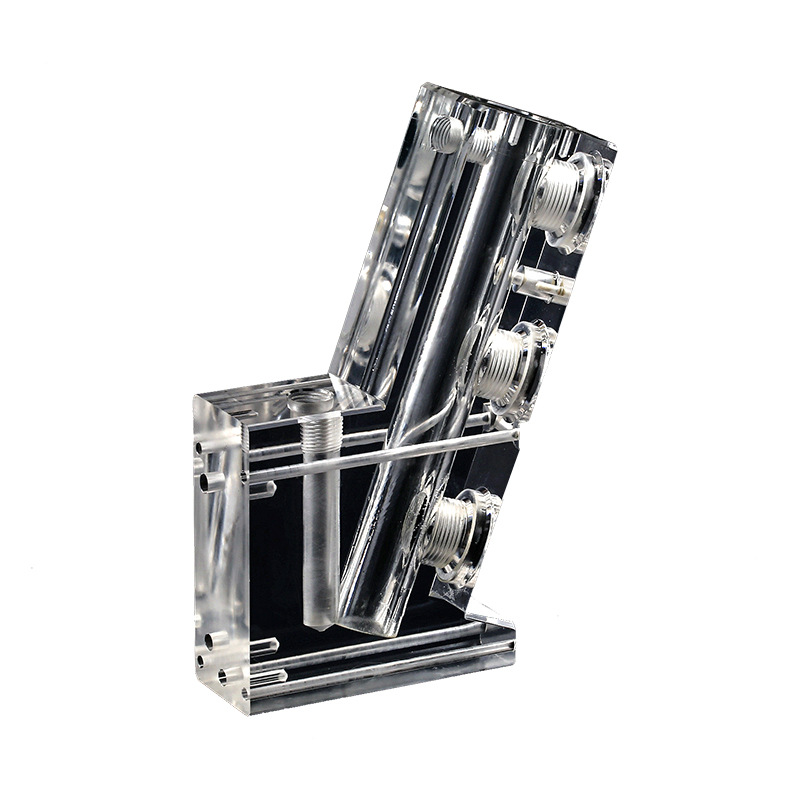

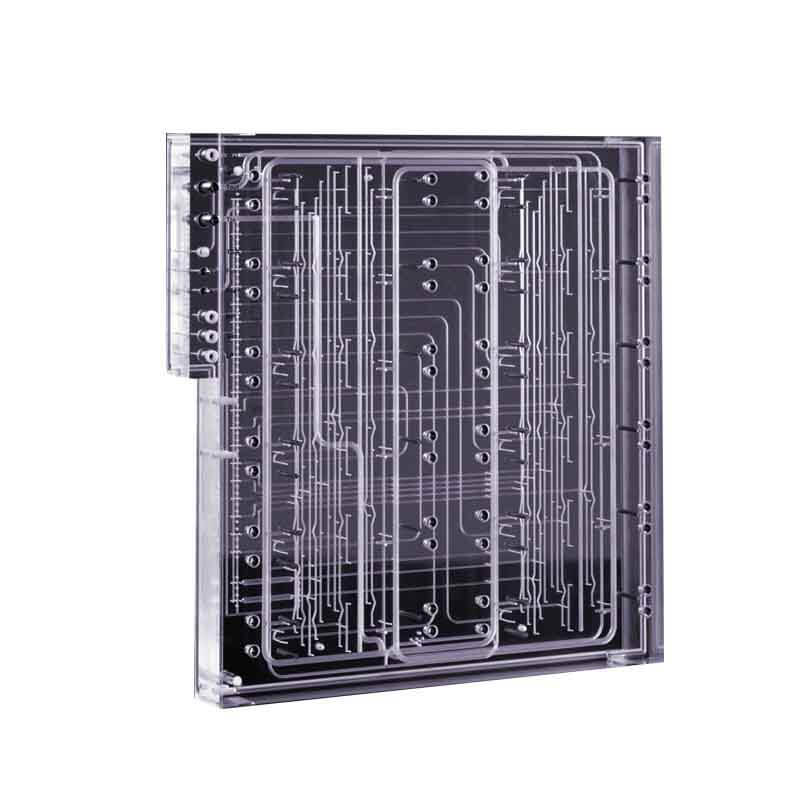

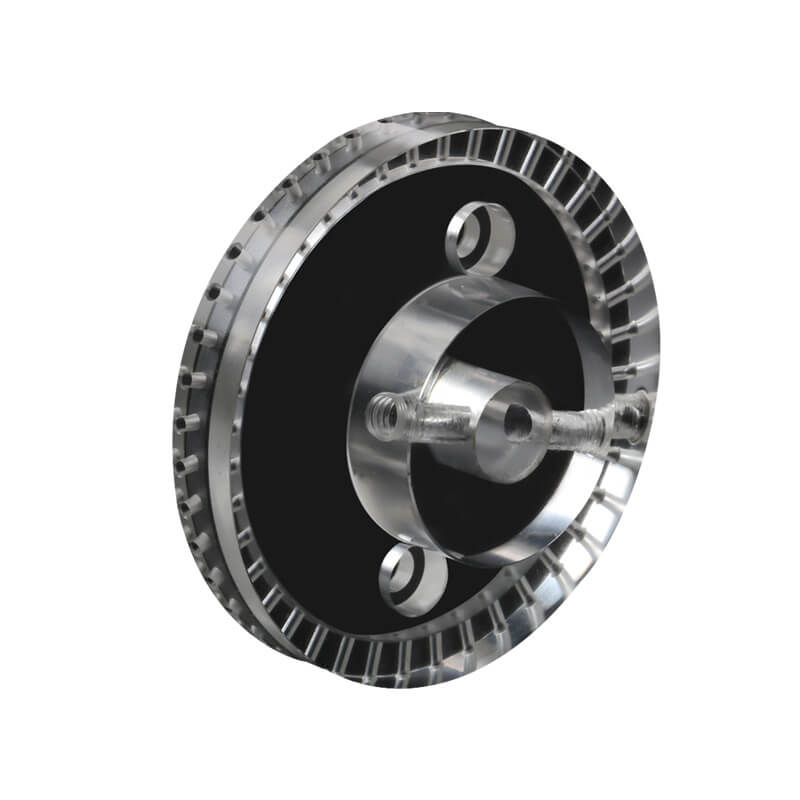

Some Picture of CNC PMMA machining Parts

CNC PMMA machining FAQs

CNC PMMA machining involves using Computer Numerical Control (CNC) equipment to cut, shape, and fabricate components from PMMA material. It requires precise tool control to achieve the desired shape and dimensions.

PMMA is favored for CNC machining due to its optical clarity, ease of machining, and lightweight properties. It is often used for applications where transparency and a smooth finish are essential.

CNC machined PMMA components are widely used in various industries, including automotive (headlamp lenses), medical devices, signage, optical lenses, and architectural elements.

Machining PMMA can be challenging due to its susceptibility to heat and potential for chipping or melting during the machining process. Proper tooling, cooling, and cutting parameters are crucial to achieve high-quality results.

CNC mills and routers equipped with sharp, high-speed cutters, such as carbide or diamond tools, are commonly used for PMMA machining. Specialized machining centers designed for precision work may also be employed.

Yes, safety precautions are important when machining PMMA. Proper ventilation, dust extraction, and personal protective equipment are recommended to mitigate exposure to potentially harmful fumes and dust.

Tolerances in CNC PMMA machining can vary depending on the specific equipment and techniques used. However, precision tolerances in the range of ±0.05 mm (0.002 inches) or better can often be achieved.

Yes, CNC machining allows for the creation of intricate and complex shapes in PMMA, making it suitable for a wide range of design requirements.

Depending on the application, some CNC machined PMMA parts may require post-processing, such as polishing or flame polishing to achieve a smooth and clear finish.

Proper disposal of PMMA machining waste and adherence to environmental regulations are important, as PMMA is a polymer. Additionally, recycling PMMA waste can be an environmentally responsible practice.

Free Sample

Explore More Plastic

Aluminum CNC Machining

Aluminum alloy is a widely used material in various fields, known for its excellent strength, lightweight properties, good thermal conductivity, corrosion resistance, cost-effectiveness, blade-friendly nature, and ease of processing. It

ABS CNC Machining

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer known for its excellent balance of material properties. It exhibits good toughness and chemical resistance, along with a range of other customizable

Brass CNC machining

Brass is a material widely used in various fields. It is an alloy composed of brass and base metal (such as zinc, previously tin). It typically exhibits color and is