Nylon CNC Machining

Nylon CNC Machining

Nylon is abbreviated as PA in English, and its full name is Polyamide. There are various types of nylon, including PA6, PA66, PA610, PA11, PA12, PA1010, PA612, PA46, and more. Nylon falls into the category of engineering plastics, which can be processed by CNC machining centers, including PA nylon. PA nylon offers advantages such as high mechanical strength, good toughness, smooth surface, low friction coefficient, wear resistance, excellent fatigue resistance, outstanding electrical properties, ease of dyeing, and easy formability.

Surface Finishes after Nylon CNC machining

| Picture | Surface finishes | Machining principle | Material | Colors | Texture | More |

|---|---|---|---|---|---|---|

| Polish | By grinding and polishing, the surface smoothness of nylon can be improved, surface roughness reduced, and overall appearance quality enhanced | N/A | N/A | Glossy | Learn More |

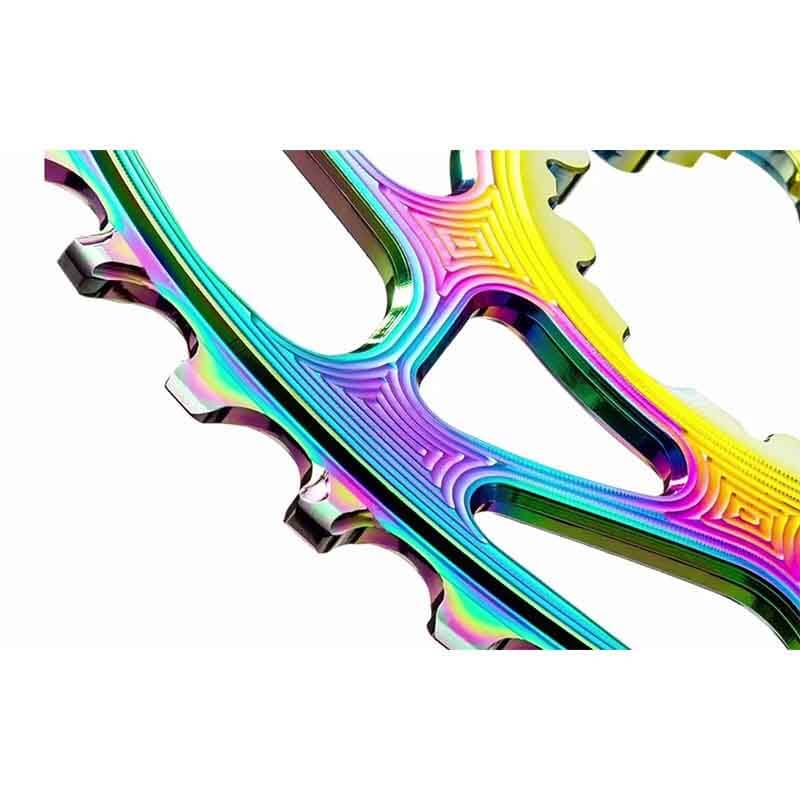

| PVD | A special coating treatment of nylon materials using PVD technology to enhance their performance and appearance, including improvements in wear resistance, corrosion resistance, and aesthetics. | PVD coating, Titanium nitride, titanium carbide, Alumina, silicon nitride | Different colors | Glossy | Learn More |

| Electroplate | Electroplating nylon can enhance its conductivity, corrosion resistance, and appearance. Commonly used electroplating metals include chromium, copper, nickel, and gold. | Silver nitrate, chemical nickel, gold powder, chromic acid | Different colors | Glossy | Learn More |

Some Picture of Nylon CNC machining Parts

CNC Nylon Machining FAQs

CNC (Computer Numerical Control) machining of nylon is a common process in manufacturing and prototyping.

nylon CNC machining is the process of shaping and cutting nylon material into desired shapes and dimensions using computer-controlled machines. CNC machines follow a specific set of instructions (programmed by a computer) to remove material and create precise parts or components from a nylon workpiece.

Various types of nylon can be machined using CNC processes, including Nylon 6, Nylon 6/6, Nylon 6/12, and Nylon 12. The choice of nylon depends on the specific application and its requirements.

CNC machining of nylon offers several advantages, including high precision, repeatability, and the ability to produce complex parts with tight tolerances. It’s suitable for both prototyping and production runs.

CNC-machined nylon parts are used in a wide range of applications, including gears, bushings, bearings, insulators, custom components for machinery, aerospace parts, medical devices, and more.

When designing parts for CNC machining in nylon, it’s essential to consider factors like tolerances, material thickness, undercuts, and part geometry to ensure the best results. CNC machining can achieve tight tolerances, but it’s crucial to design parts that are manufacturable.

Yes, CNC machining allows for high levels of customization. You can create parts with intricate features, different sizes, shapes, and finishes based on your specific requirements.

Compared to nylon injection molding, the only limitation of nylon CNC machining is the higher cost and longer processing time for large-scale production. Additionally, nylon can generate heat during machining, so adequate cooling and tooling considerations are important.

The surface finish of CNC-machined nylon parts can range from rough to very smooth, depending on the machining process and tooling used. Post-processing steps like sanding or polishing can further improve the surface finish.

Nylon itself is not environmentally harmful, but it’s essential to follow appropriate waste disposal and recycling procedures to manage any waste generated during the CNC machining process.

The cost of CNC nylon machining depends on various factors, including the complexity of the part, material type, quantity, and post-processing requirements. It’s generally cost-effective for low to medium production quantities and when precision is crucial.

Free Sample

Explore More Plastic Materials

CNC POM Machining

POM (Polyoxymethylene) is an important semi-crystalline thermoplastic engineering plastic known for its impact resistance and wear resistance. It is widely used in industries such as automotive, electronics, and machinery and

CNC Machining Titanium

Titanium is a lustrous transition metal with a silver color, low density, and high strength. It is an ideal material for typical applications in aerospace, medical, military, chemical processing, marine

Copper CNC Machining

Copper, also known as pure copper, is classified into T1 to T44 based on its purity, with a higher number indicating a higher impurity content. It is also referred to