PC CNC Machining

PC CNC Machining

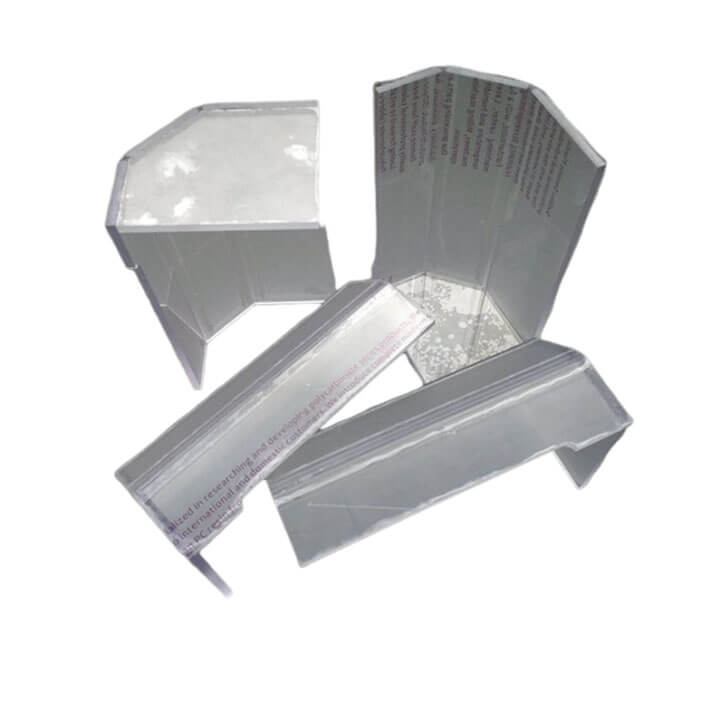

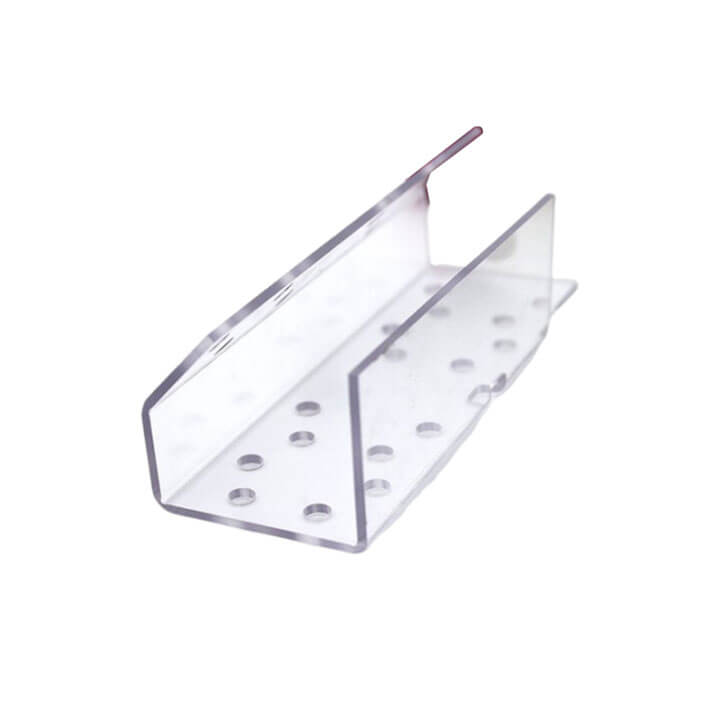

PC sheets, also known as polycarbonate sheets or polyester sheets, are characterized by high transparency, lightweight, impact resistance, sound insulation, heat insulation, flame resistance, and resistance to aging. They are a high-tech, environmentally friendly plastic material with outstanding comprehensive properties. The common method for processing PC sheets is CNC machining, which involves engraving, drilling, and milling slots on PC sheet materials. PC sheet engraving processes include hole positioning, precision cutting, and milling machine groove processing. PC sheets can be processed into vehicle PC protective covers, transparent plastic protective covers, PC windshield glass, PC glass windows, and more.

Some Picture of PC CNC Machining Parts

PC CNC Machining FAQs

CNC machining of PC boards refers to engraving, drilling, milling slots, and other processes on PC sheet materials. The scope of PC sheet engraving includes: hole positioning, precision cutting, and milling machine groove processing, etc.

Yes, polycarbonate (PC) is a suitable material for CNC machining due to its excellent mechanical properties, impact resistance, and optical clarity.

Free Sample

Explore More Plastic Materials

CNC PMMA Machining

PMMA is a material with high mechanical strength, strong dimensional stability, and excellent resistance to creep. PMMA sheet is a high-performance acrylic glass widely used in applications such as construction,

Magnesium CNC Machining

Magnesium alloy materials are primarily composed of magnesium, supplemented by other elements such as aluminum, zinc, manganese, cerium, and thorium, forming magnesium alloys. Magnesium alloys are often chosen as materials

Aluminum CNC Machining

Aluminum alloy is a widely used material in various fields, known for its excellent strength, lightweight properties, good thermal conductivity, corrosion resistance, cost-effectiveness, blade-friendly nature, and ease of processing. It