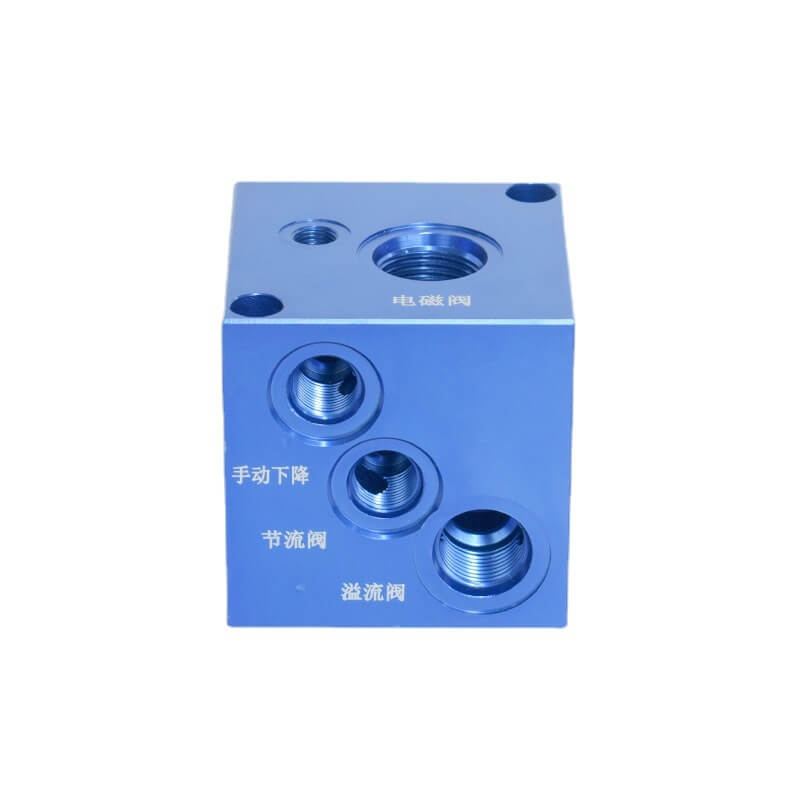

Aluminum Hydraulic Manifold Block

Aluminum Hydraulic Manifold Block

Aluminum Hydraulic Manifold Block manufacturer in China.

MOQ Starts from 1pcs.

As an Aluminum Hydraulic Manifold Block manufacturer, Masion provides high-quality custom different hydraulic block manifold services to customers with outstanding production advantages, advanced technological capabilities, and professional solutions offerings.

Masion Capability

High Capacity, Proper Price

10000pcs production capacity per month make the price lower.

Free Samples, Low MOQ

1pcs MOQ make you order flexibly with one free sample for you testing.

Certified Factory, Guaranteed Quality

ISO9001:2008 and strictly 100% inspection guarantee quality and CMM inspection equipment.

High precision, thick gold

With 0.005mm tolerance and with different surface finishing and different materials.

Our Products

What Sets Us Apart

Strong Experience

With 16 years of hydraulic block manifold machining expertise, we focus on high-quality, customized solutions for different hydraulic block manifold demands.

Advanced Machine

30 sets precision 3,4,5 axis CNC machining center with mature and stable manufacturing processes with technical machinist and engineer.

Surprised Price

Stockpiling a large amount of conventional materials and having a mature production process can reduce the overall price by 5%.

24/7 Engineering Support

Masion is specializing in offering 24/7 engineering support, design services, cost reduction, quality assurance, and smooth product transitionsunparalleled excellence etc.

CNC milling parts Manufacturing Process

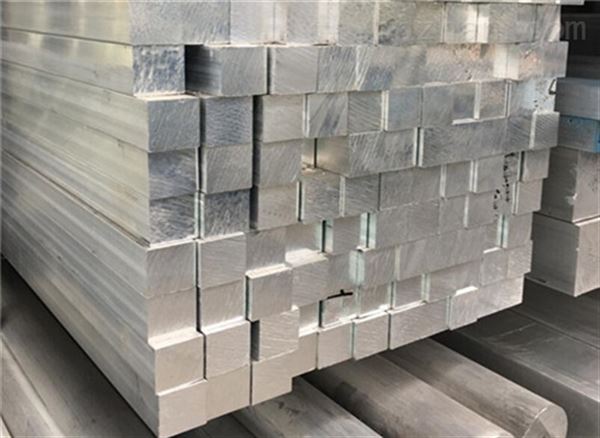

Raw Material

In the preparation stage of aluminum materials, it is typically required that the materials conform to specified model requirements and meet standard performance criteria. Additionally, we maintain a regular inventory of product materials to address any issues related to insufficient delivery time.

Hydraulic block manifold Machining

- Milling

- Drilling

- Threading

- Cutting

- Countersinking

- Boring

- Tapping

- Reaming

Surface Finish

- The aluminum hydraulic valve block can undergo an anodizing process to alter its appearance, achieving various oxidation colors such as black, blue, red, gold, green, and more. Aluminum anodizing treatment enhances the aesthetic appeal, wear resistance, and corrosion resistance of the hydraulic valve block.

Packing

- For hydraulic manifold block. with extremely high requirements, we pack the part one by one with PC bag, or blister bag etc.

- For hydraulic manifold block. with moderate requirements, we also perform packing the bag as clients need.

- For hydraulic manifold block. with no packaging requirements, we will arrange the products neatly and separate them with cardboard.

Quality Control(Testing)

- Masion conduct material inspections to ensure the parts correctness.

- Masion perform initial inspections on the first samples; production proceeds only if the dimensional inspection is passed, with adjustments made if necessary for non-compliance.

- Masion conduct sample inspections on the manufactured products to ensure compliance with the dimensional requirements specified in the drawings.

Application Area

Hydraulic Manifold Block FAQs

A hydraulic manifold block is a component in hydraulic systems that serves as a central distribution point for hydraulic fluid. It typically contains channels, ports, and valves to control the flow of hydraulic fluid between various components such as pumps, valves, and actuators.

A hydraulic manifold block is a crucial component in hydraulic systems, designed to regulate fluid flow between pumps and actuators, such as hydraulic cylinders and motors, and other system components. It acts as a control center by directing fluid to different parts of the hydraulic system, ensuring efficient and accurate operations.

Integration of Hydraulic Components: The manifold block consolidates various hydraulic components such as valves, pumps, and actuators into a single, compact unit. This integration simplifies the hydraulic circuit and reduces the need for numerous hoses and connectors, which can be potential leak points.

Channeling Fluid Flow: Inside the manifold block are drilled channels and passages. These channels are strategically designed to direct hydraulic fluid to and from different components within the system.

Valve Incorporation: Valves are often integrated into the manifold block. These valves, which can include directional control valves, pressure relief valves, and check valves, regulate the flow and pressure of the hydraulic fluid. By controlling these valves, the manifold can direct fluid flow in a specific sequence or path, manage the pressure within the system, and control the speed and force of actuators.

Operation of Actuators: The fluid’s flow from the manifold block to various actuators (like hydraulic cylinders or motors) enables the actuators to perform their intended actions, such as lifting, pressing, or turning. The precise control of fluid flow and pressure ensures that these actions are carried out efficiently and accurately.

Heat Dissipation and Filtration: Some manifold blocks are also designed to help dissipate heat and may include provisions for fluid filtration, further contributing to the overall efficiency and longevity of the hydraulic system.

Customization for Specific Applications: Manifold blocks can be custom designed for specific applications, taking into account factors like the type of fluid used, operating pressure, flow rate, and environmental conditions.

Hydraulic manifold blocks, which are essential components in hydraulic systems, are typically made from a variety of materials. The choice of material usually depends on the application’s specific requirements, such as pressure ratings, environmental conditions, system pressure, fluid compatibility, and application requirements and cost constraints. Common materials used include:

Steel: Often used for high-pressure applications due to its strength and durability. Steel manifold blocks can withstand significant pressure and are resistant to wear and tear.

Aluminum: Popular for its lightweight properties, aluminum is used in applications where weight is a critical factor, such as in aerospace or mobile hydraulics. It’s also easier to machine than steel, but it has a lower pressure rating.

Ductile Iron: This material offers good strength and durability, similar to steel, but at a lower cost. Ductile iron is often used in medium to high-pressure applications.

Stainless Steel: Chosen for its corrosion resistance, stainless steel is ideal for harsh environments or applications where the fluid being used might corrode other materials.

Brass: Sometimes used for lower pressure applications or in environments where corrosion resistance is important but stainless steel is not necessary.

Composite Materials: In some specialized applications, composites may be used for their unique properties like corrosion resistance, lightweight, or thermal insulation.

Yes, hydraulic manifold blocks are often designed with modularity and customization in mind. This allows for the integration of specific valves, ports, and features tailored to the requirements of a particular hydraulic system.

Specific Flow Paths and Circuitry: Custom manifold blocks can be designed with specific internal flow paths and circuitry to match the unique requirements of the hydraulic system. This includes determining the size and placement of channels and ports to facilitate the desired fluid flow and pressure.

Material Selection: Depending on the application, manifold blocks can be made from different materials such as aluminum, steel, stainless steel, or ductile iron, each offering different benefits in terms of strength, weight, and corrosion resistance.

Integration of Valves and Components: Custom manifolds can incorporate various valves (like relief valves, check valves, directional control valves) and other components in specific configurations to suit the application’s needs.

Size and Shape: The physical dimensions and shape of the manifold can be tailored to fit into specific spaces within a machine or system, accommodating size constraints and integration with other components.

Pressure and Temperature Ratings: Based on the operational requirements, custom manifolds are designed to withstand specific pressure ranges and temperatures.

Port Sizes and Types: Customization allows for specific port sizes and types to be incorporated, ensuring compatibility with other components in the hydraulic system.

Surface Treatment: Depending on the environment in which the manifold will operate, it can receive various surface treatments for corrosion resistance or enhanced durability.

Additional Features: Features like built-in sensors for pressure or temperature monitoring, or provisions for heat dissipation, can be included in the design.

Currently, common aluminum alloys used for hydraulic manifold blocks include:

6061 Aluminum Alloy:

Characteristics: Hard aluminum alloy with high hardness, corrosion resistance, and ease of processing.

Applications: Suitable for manufacturing components such as displacement plates and flanges in hydraulic manifold blocks.

5083 Aluminum Alloy:

Characteristics: Superhard aluminum alloy with high strength, toughness, and corrosion resistance.

Applications: Ideal for manufacturing components like cylinders and pressure caps within hydraulic manifold blocks.

7075 Aluminum Alloy:

Characteristics: Superhard aluminum alloy with high strength, good plasticity, and wear resistance.

Applications: Suited for manufacturing components like pistons and valve sleeves in hydraulic manifold blocks.

Different types of aluminum materials exhibit specific characteristics, mainly in the following aspects:

Hardness:

Varies among aluminum alloys, chosen based on the requirements of different components.

Corrosion Resistance:

Essential for hydraulic systems using hydraulic oil; aluminum materials must possess corrosion resistance.

Machinability:

Should be easy to machine and exhibit strong cutting performance to meet manufacturing process needs.

Strength:

The strength of aluminum materials should suit the environmental conditions and loads borne by different components.

Different types of aluminum materials are suitable for various components, as follows:

6061 Aluminum Alloy:

Commonly used for displacement plates, flanges, and similar components.

5083 Aluminum Alloy:

Ideal for manufacturing cylinders, pressure caps, and related components.

7075 Aluminum Alloy:

Suited for components such as pistons and valve sleeves.

To ensure the quality of hydraulic manifold blocks, implement the following measures:

Strict Quality Control Processes:

Establish and enforce rigorous quality control processes, including inspections and tests at each production stage.

Qualified Suppliers and Material Selection:

Choose reliable suppliers and ensure purchased materials meet quality standards through regular supplier evaluations.

Precise Dimensions and Geometry:

Ensure accurate dimensions and geometry during the design phase and use precision machining and measurement tools in production.

Appropriate Material Selection:

Choose materials based on hydraulic system conditions, ensuring sufficient strength, corrosion resistance, and wear resistance.

Comprehensive Testing and Inspection:

Conduct thorough testing, including pressure, leakage, and temperature tests, to verify product performance and reliability.

Document Records and Traceability:

Establish a comprehensive document recording system to track production history and quality control information.

Employee Training:

Ensure proper training for production staff on quality standards, operating procedures, and equipment monitoring.

Improvement and Feedback Mechanism:

Implement a quality improvement and feedback mechanism, encouraging employees to propose enhancements, promptly addressing quality issues, and continuously improving production processes.

Free Sample

Explore Other Products

CNC Turning

Stainless Steel stethoscope Chestpiece and another different CNC turning Parts.

CNC Milling & Turning Combination

Roller shaft,Turn-milling composite processing, 7075 aluminum machining, and another turning and milling CNC machining parts.

Automatic Lathe

Test Pin and other Automatic Lathing Machining Parts such as screws,copper pillar, knob, etc.