Multi Jet Fusion

Multi Jet Fusion

Compared to the Selective Laser Sintering (SLS) process, the material used is a nylon-based polymer material. The distinction lies in the addition of additives and a refining agent, in addition to molding powder. This process is employed while the previous layer is still in a molten state. Printing a new layer of material and applying a print agent on top of it ensures the perfect fusion of the two layers, resulting in durable, high-quality, clear, and functionally robust 3D printed components.

MJF Technology Schematic

Working Principle:

The process begins by spreading a powder layer, followed by the application of a solvent and material for fine treatment, ensuring precision at the print edges and guaranteeing the desired strength and texture of the finished product. When a heat source is involved, these steps are repeated until the entire object is layer-by-layer printed.A “fluid” is sprayed onto the printing area (i.e., the cross-section of the printed item) to completely dissolve the powder material. Subsequently, “fine powder” is sprayed onto the outer edges of the printing area to provide thermal insulation. This approach helps maintain the looseness of the unprinted powder, increasing the powder’s reuse rate (80%, compared to the typical SLS reuse rate of about 50%) and smoothing the surface of the printed layers, thereby enhancing printing precision.

Pros and Cons

Advantages

- Suitable for parts with complex structures and unique geometries, ideal for small-batch/customized production.

- Excellent material strength without the need for added support structures.

- Short processing cycles and low costs.

- Optimized structures and open-minded design approach.

Disadvantages

- Surface quality is not as good as SLA resin 3D printing.

- Available materials are temporarily limited to industry applications.

- Available materials are limited to colors, light gray, or charcoal black.

Optional Material

- Highly reusable PA12 nylon material

- Characteristics: Excellent strength, secondary processing assembly, may exhibit a cement-like appearance.

- Typical Applications: 3D printing for performance testing, small-batch production.

Application Scope

- Validation of functional tests, such as prototype processing for appearance or research and development design.

- Small-batch customization/personalized printing, including 3D printing for custom gifts.

- Suitable for industries requiring precision and complex structures, such as aerospace, medical, molds, 3D printing surgical guides, etc.

Explore Other Products

Automatic Lathe

Test Pin and other Automatic Lathing Machining Parts such as screws,copper pillar, knob, etc.

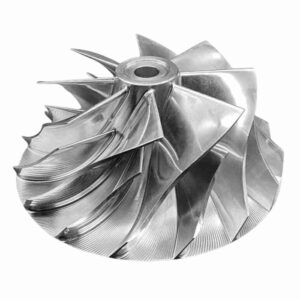

Aluminum Boat Impeller

Five-axis simultaneous complex parts machining, aluminum boat impeller, watercraft impeller, compressor impeller, turbocharger impeller,and another different 5-axis CNC parts etc.

CNC Milling & Turning Combination

Roller shaft,Turn-milling composite processing, 7075 aluminum machining, and another turning and milling CNC machining parts.