Polyaxial Pedicle Screw

Polyaxial Pedicle Screw

Swiss lathing bone screw manufacturers,bone screw orthodontic, polyaxial pedicle screw, Acl Screwsdental screw, manufacturer in China.

MOQ Starts from 1pcs.

As a specialized Swiss lathing bone screw manufacturer, bone screw orthodontic polyaxial pedicle screw manufacturer, Masion provides high-quality custom bone screw orthodontic and, polyaxial pedicle screw, Acl Screws, dental screw services to customers with outstanding production advantages, advanced technological capabilities, and professional solution offerings.

Masion Capability

High Capacity, Proper Price

5000pcs production capacity per month make the price lower.

Free Samples, Low MOQ

1pcs MOQ make you order flexibly with one free sample for you testing.

Certified Factory, Guaranteed Quality

ISO9001:2008 and strictly 100% inspection guarantee quality and CMM inspection equipment.

High precision, Good Surface

With 0.05mm tolerance and with different surface finishing.

Our Products

What Sets Us Apart

Strong Experience

With 16 years of Swiss Lathe Parts machining expertise, we focus on high-quality, customized solutions for different Swiss Lathe Parts demands.

Advanced Imported Machine

30 sets precision imported Japanese Citizen Swiss CNC Lathe with mature and stable manufacturing processes with technical machinist and engineer.

Surprised Price

Stockpiling a large amount of conventional materials and having a mature production process can reduce the overall price by 5%.

24/7 Engineering Support

Masion is specializing in offering 24/7 engineering support, design services, cost reduction, quality assurance, and smooth product transitionsunparalleled excellence etc.

Swiss CNC machining dental screw, ACL screw Manufacturing Process

Raw Material

Swiss CNC Shaft Machining

- Milling

- Turning

- Drilling

- Threading

- Cutting

- Counter Sinking

- Boring

- Knurling

- Grooving

- Taper

- Turning

- Tapping

- Reaming

Surface Finish

Swiss CNC machining titanium dental screw, ACL screwcan undergo anodizing or PVD treatment for color variety and enhanced wear resistance.

Packing

- For dental screw, ACL screw with very high packaging requirements, we will package the products individually, using ziplock bags, or foam bags, or pearl cotton bags, or blister box and then separate with cardboard, and finally use carton packaging then send to the medical company to aseptic packaging with sealable bag.

Quality Control (Testing)

- Masion conduct material inspections to ensure the shafts correctness.

- Masion perform initial inspections on the first samples; production proceeds only if the dimensional inspection is passed, with adjustments made if necessary for non-compliance.

- Masion conduct sample inspections on the manufactured products to ensure compliance with the dimensional requirements specified in the drawings.

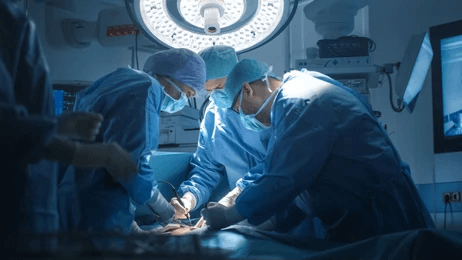

Application Area

Swiss lathe CNC machining bone screw FAQs

A polyaxial pedicle screw is a medical device used in spinal surgery for the treatment of various spinal conditions, particularly in spinal fusion procedures. The pedicle screw is an implant designed to be inserted into the pedicle of a vertebral bone, and it plays a crucial role in stabilizing the spine during fusion.

Here are the key aspects of a polyaxial pedicle screw and its uses:

Spinal Stabilization:

The primary purpose of polyaxial pedicle screws is to provide stability to the spine, especially in cases where spinal fusion is required. Spinal fusion involves the joining of two or more vertebrae to promote bone growth between them, stabilizing the spine and reducing pain caused by movement.

Flexibility in Placement:

The term “polyaxial” refers to the screw’s ability to move in multiple directions. The screw head has a ball-and-socket design, allowing it to articulate in various planes. This flexibility is advantageous during surgery as it allows the surgeon to adjust the angle of the screw head for optimal placement.

Accommodating Vertebral Anatomy:

The polyaxial design is particularly useful when dealing with variations in vertebral anatomy. Since the screw can move in multiple directions, it provides surgeons with more options for navigating around anatomical structures and adapting to the patient’s specific spinal characteristics.

Connection to Rods:

Polyaxial pedicle screws are often used in conjunction with rods. The screws are attached to the rods, and the combination provides stabilization and support to the spine during the fusion process.

Facilitating Surgical Procedures:

The flexibility of polyaxial screws can make them easier to handle during surgery. Surgeons can more easily align and insert the screws, making the overall procedure smoother.

Patient-Specific Adaptability:

The ability to adjust the screw’s angulation allows for a more patient-specific approach. Surgeons can tailor the placement of the screws based on the individual anatomy of the patient.

In summary, polyaxial pedicle screws are valuable tools in spinal surgery, offering flexibility in placement and adaptability to the unique anatomical features of each patient. They contribute to the success of spinal fusion procedures by providing stability and support to the spine, ultimately improving the patient’s quality of life by reducing pain and promoting spinal integrity.

The primary difference between polyaxial and monoaxial screws lies in their range of motion and design. Here’s a breakdown of the distinctions:

Polyaxial Screws:

Range of Motion: Polyaxial screws have a ball-and-socket design, allowing movement in multiple directions. This means that the screw head can articulate in various planes.

Flexibility in Placement: The polyaxial design provides greater flexibility during placement. Surgeons can adjust the angle of the screw head, making it easier to navigate around anatomical structures and adapt to the patient’s specific spinal anatomy.

Complexity: The ball-and-socket mechanism adds complexity to the design, but it offers advantages in terms of adaptability and flexibility during surgery.

Typical Use: Polyaxial screws are often used in situations where precise alignment is challenging or when the surgeon needs more flexibility during the implantation process.

Monoaxial Screws:

Range of Motion: Monoaxial screws, in contrast, have a more limited range of motion. The screw head allows movement in only one direction, typically along a single axis.

Placement Direction: These screws are generally placed in a fixed direction during surgery, and their movement is constrained compared to polyaxial screws.

Simplicity: Monoaxial screws are simpler in design compared to polyaxial screws. They lack the ball-and-socket mechanism, which can make them easier to handle.

Typical Use: Monoaxial screws are often used in cases where movement in a single plane is sufficient for stabilization. They may be preferred in straightforward spinal surgeries where precise alignment is not as critical.

In summary, the choice between polyaxial and monoaxial screws depends on factors such as the complexity of the surgery, the need for precise alignment, and the surgeon’s preferences. Polyaxial screws provide greater flexibility and adaptability, while monoaxial screws are simpler in design and may be preferred in cases where movement in a single direction is adequate for stabilization. The selection is often based on the specific requirements of the surgical procedure and the patient’s spinal anatomy.

Free Sample

Explore Other Products

Automatic Lathe

Test Pin and other Automatic Lathing Machining Parts such as screws,copper pillar, knob, etc.

CNC Turning

Stainless Steel stethoscope Chestpiece and another different CNC turning Parts.

Swiss CNC Machining

Custom Swiss CNC turningTC4 titanium alloy Anodizingmedical dental nail bone nail.