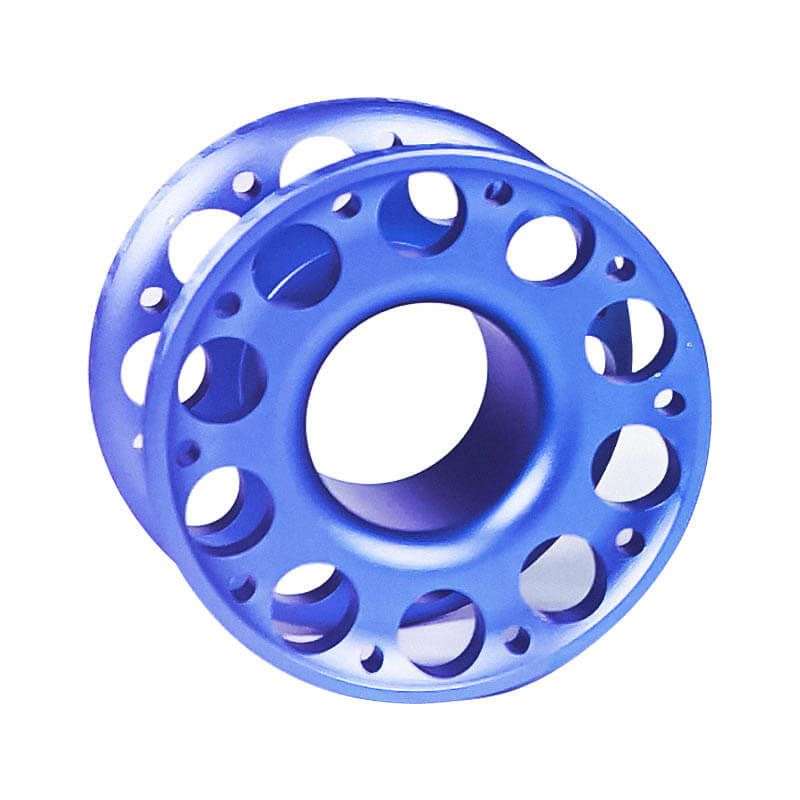

Scuba Finger Reel

Scuba Finger Reel

Scuba Finger Reel manufacturer in China.

MOQ Starts from 1pcs.

As a specialized Scuba Finger Reel manufacturers,Masion provides high-quality custom different Scuba Finger Reel services to customers with outstanding production advantages, advanced technological capabilities, and professional solution offerings.

Masion Capability

High Capacity, Proper Price

10000pcs production capacity per month make the price lower.

10000pcs production capacity per month make the price lower.

Free Samples, Low MOQ

Certified Factory, Guaranteed Quality

ISO9001:2008 and strictly 100% inspection guarantee quality and CMM inspection equipment.

High precision, thick gold

With 0.005mm tolerance and with different surface finishing and different materials.

Our Products

What Sets Us Apart

Strong Experience

With 16 years of Turning milling Scuba Finger Reel machining expertise, we focus on high-quality, customized solutions for different Scuba Finger Reel demands.

Advanced Machine

20 sets precision turning and milling lathe with mature and stable manufacturing processes with technical machinist and engineer. We could manufacture different Scuba Finger Reel to meet your need.

Surprised Price

Stockpiling a large amount of conventional materials and having a mature production process can reduce the overall price by 5%.

24/7 Engineering Support

Masion is specializing in offering 24/7 engineering support, design services, cost reduction, quality assurance, and smooth product transition sun paralleled excellence etc.

Stainless steel turning milling parts Manufacturing Process

Raw Material

At different stages of material preparation, various materials such as aluminum, PEEK, POM, etc., can be chosen to manufacture custom Swiss Lathe Parts. Additionally, we offer regular product material inventory to address any issues related to insufficient delivery times.

Stainless steel turning milling parts Machining

- Milling

- Turning

- Drilling

- Threading

- Cutting

- Countersinking

- Boring

- Knurling

- Grooving

- Taper

- Tapping

- Reaming

Surface Finish

- Aluminum Scuba Finger Reels can undergo oxidation treatment to showcase various colors, meeting the personalized aesthetic preferences of customers. This oxidation process may include camouflage oxidation to fulfill the higher oxidation effect requirements of specific clients.

- For plastic components of Scuba Finger Reels, water transfer printing can be employed. Through this method, different colors and patterns can be applied to the surface of the plastic, creating diverse aesthetic effects. This approach enhances the product's visual diversity, catering to the aesthetic preferences of various customers.

Packing

- For customers with customization requirements, we offer personalized packaging services tailored to their needs. This includes custom Logo colored boxes and Logo cardboard boxes according to the customer's specifications.

- For customers without specific customization requests, we use neutral packaging, including neutral colored boxes and neutral cardboard boxes.

Quality Control(Testing)

- Masion conduct material inspections to ensure the partss correctness.

- Masion perform initial inspections on the first samples; production proceeds only if the dimensional inspection is passed, with adjustments made if necessary for non-compliance.

- Masion conduct sample inspections on the manufactured products to ensure compliance with the dimensional requirements specified in the drawings.

Application Area

Scuba Finger Reel FAQs

Scuba Finger Reels are often made from lightweight and durable materials such as aluminum or plastic.

The anodizing treatment on aluminum Scuba Finger Reels serves to provide different colors and may include camouflage anodizing for clients with specific aesthetic preferences.

Water transfer printing is a method used to apply various colors and patterns to the surface of plastic components, enhancing the visual appearance of the product.

Yes, we offer customized packaging services for customers with specific requirements. This includes the option to design and produce Logo-colored boxes and Logo cardboard boxes according to their preferences.

Neutral packaging for customers without specific requests typically includes neutral-colored boxes and neutral cardboard boxes.

Yes, Scuba Finger Reels are often available in various sizes and specifications to cater to different preferences and diving needs.

The manufacturing process for Scuba Finger Reels involves shaping, machining, and assembling the components, followed by surface treatments such as oxidation for aluminum or water transfer printing for plastic.

While primarily designed for scuba diving, Scuba Finger Reels can also be used for other water activities that require navigation and line management, such as snorkeling or underwater exploration.

We typically offer a 2-year warranty. If you encounter any quality issues, we are ready to provide replacement services at any time, ensuring that your market customers receive a faster and more timely quality assurance.

You can typically place orders by contacting us directly. Just send an email for any inquiries, including pricing, delivery time, etc. We will respond promptly and provide you with the necessary information in a timely manner.

Free Sample

Explore Other Products

Swiss CNC Machining

Custom Swiss CNC turningTC4 titanium alloy Anodizingmedical dental nail bone nail.

CNC Milling

CNC Milling Aluminum different automobile hub, and different 3-axis, 4-axis,5 axis CNC machining parts.

CNC Milling & Turning Combination

Roller shaft,Turn-milling composite processing, 7075 aluminum machining, and another turning and milling CNC machining parts.