Selective Laser Melting

Selective Laser Melting

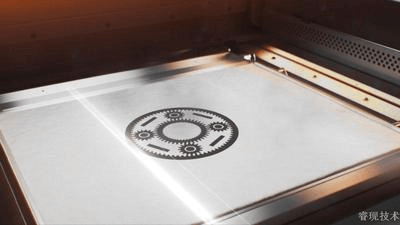

Selective Laser Melting (SLM) and EBSM/EBM (Electron Beam Melting metal 3D printing) share similar technical principles, utilizing laser irradiation to pre-diffuse metal powder and form metal components. The difference lies in the heat source.

Selective Laser Melting technology (metal 3D printing) employs finely focused spots to rapidly melt pre-set powder materials with a particle size of 300-500 mesh, ensuring perfect metallurgical bonding for nearly any shape and functional component. Achieving densities close to 100%, size accuracy within 20-50 micrometers, and surface roughness of 20-30 micrometers. This promising rapid prototyping technique has expanded into aerospace, medical, automotive, mold, and other fields.

SLM Technology Schematic

Working Principle:

With direct metal laser sintering, customers only need to provide the relevant data format. Single layers are connected and solidified through laser high-temperature sintering, while sub-layers are connected layer by layer through a powder feeding device. This innovative technology is carried out in a processing chamber protected by inert gas to prevent metal reactions with other gases at high temperatures.

Due to the energy and residual stresses generated during sintering, the component must be connected to a fixed baseplate via support structures to prevent warping deformation.

Pros and Cons

Advantages

- Suitable for parts with complex structures and unique geometries, ideal for small-batch/customized production.

- Short processing cycles, low cost for complex parts.

- Optimized structures and open-minded thinking.

Disadvantages

- Lower accuracy in initial processing, often requiring secondary treatment.

- Available materials are temporarily limited by industry applications.

Optional Material

- Aluminum Alloy: AISi10Mg

- Properties: Low density, high thermal conductivity

- Typical Applications: Customized products, automotive, aerospace, etc.

- High-Temperature Alloy: Ni718

- Properties: High-temperature resistance, corrosion resistance, fatigue resistance

- Typical Applications: Oilfield energy, automotive, aerospace, etc.

- Mold Steel: MS1

- Properties: High hardness, polishable, good thermal conductivity

- Typical Applications: Injection molds, rapid prototypes, aerospace, etc.

- Titanium Alloy: Ti64

- Properties: Lightweight, biocompatibility, corrosion resistance

- Typical Applications: Biomedical implants, aerospace, etc.

Application Scope

- Validate R&D design for appearance or functional testing.

- Small-batch customization/personalization.

- Suitable for industries requiring precise and complex mechanisms, such as aerospace, healthcare, and molds.

Explore Other Products

Swiss CNC Machining

Custom Swiss CNC turningTC4 titanium alloy Anodizingmedical dental nail bone nail.

3D pringting

Masionprovides a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering), MJF (Multi Jet Fusion), and DLMS (Direct Metal Laser Sintering).

CNC Turning

Stainless Steel stethoscope Chestpiece and another different CNC turning Parts.