Stainless Steel Turning and Milling Parts

Stainless Steel Turning and Milling Parts

Stainless steel turning milling parts manufacturer in China.

MOQ Starts from 1pcs.

As a specialized stainless steel turning milling parts manufacturers,Masion provides high-quality custom different stainless steel turning milling parts services to customers with outstanding production advantages, advanced technological capabilities, and professional solution offerings.

Masion Capability

High Capacity, Proper Price

10000pcs production capacity per month make the price lower.

Free Samples, Low MOQ

1pcs MOQ make you order flexibly with one free sample for you testing.

Certified Factory, Guaranteed Quality

ISO9001:2008 and strictly 100% inspection guarantee quality and CMM inspection equipment.

High precision, thick gold

With 0.005mm tolerance and with different surface finishing and different materials.

Our Products

What Sets Us Apart

Strong Experience

With 16 years of Turning machining and 5 years stainless steel turning milling parts machining expertise, we focus on high-quality, customized solutions for different turning milling parts demands.

Advanced Machine

20 sets precision turning and milling lathe with mature and stable manufacturing processes with technical machinist and engineer. We could manufacture different stainless steel turning milling parts to meet your need.

Surprised Price

Stockpiling a large amount of conventional materials and having a mature production process can reduce the overall price by 5%.

24/7 Engineering Support

Masion is specializing in offering 24/7 engineering support, design services, cost reduction, quality assurance, and smooth product transition sun paralleled excellence etc.

Stainless steel turning milling parts Manufacturing Process

Raw Material

During the Stainless Steel materials preparation stage, it is typically required for the materials to have good smoothness and high concentricity, facilitating smooth usage on the automatic lathe feeding rack. Additionally, we offer a regular product material inventory to address any issues related to insufficient delivery lead times.

Stainless steel turning milling parts Machining

- Milling

- Turning

- Drilling

- Threading

- Cutting

- Countersinking

- Boring

- Knurling

- Grooving

- Taper

- Tapping

- Reaming

Packing

- For stainless steel turning milling parts. with extremely high requirements, we pack the part one by one with PC bag, or blister bag etc.

- For stainless steel turning milling parts. with moderate requirements, we also perform packing the bag as clients need.

- For stainless steel turning milling parts. with no packaging requirements, we will arrange the products neatly and separate them with cardboard.

Quality Control(Testing)

- Masion conduct material inspections to ensure the partss correctness.

- Masion perform initial inspections on the first samples; production proceeds only if the dimensional inspection is passed, with adjustments made if necessary for non-compliance.

- Masion conduct sample inspections on the manufactured products to ensure compliance with the dimensional requirements specified in the drawings.

Application Area

Stainless steel turning milling parts FAQs

Stainless steel turning and milling is a machining process used to create precision parts from stainless steel materials. It involves using lathes and milling machines to cut, shape, and finish stainless steel workpieces to specific dimensions and tolerances.

Stainless steel is chosen for its corrosion resistance, strength, durability, and aesthetic appeal. It is often used in industries where parts must withstand harsh environments or maintain a polished appearance.

Common stainless steel grades used for turning and milling include 303, 304, 316, 316L, and 17-4 PH. The choice of grade depends on the specific application and requirements.

The advantages include high precision, tight tolerances, excellent surface finish, and the ability to produce complex geometries. Stainless steel parts are also resistant to rust and corrosion.

Stainless steel turning and milling parts are used in a wide range of industries, including automotive, aerospace, medical, electronics, food processing, and more.

Turning involves rotating a workpiece on a lathe while a cutting tool removes material from its outer diameter. Milling, on the other hand, uses a rotating cutter to remove material from the workpiece’s surface.

Stainless steel turned and milled parts are used in applications such as shafts, fasteners, fittings, valves, surgical instruments, and aerospace components, among others.

Consider factors such as the supplier’s experience, technical capabilities, quality certifications, pricing, and reputation. Visiting the supplier’s facility and requesting references can also help in the selection process.

Quality standards may include ISO 9001 certification and industry-specific standards. It’s important to ensure that the supplier adheres to the necessary quality standards for your application.

The cost depends on factors like material choice, complexity of the part, tolerances, quantity, and supplier pricing. It’s important to obtain quotes from multiple suppliers to compare costs.

Yes, stainless steel parts can be customized to meet specific design and performance requirements. Customization includes material selection, geometry, surface finish, and more.

Lead times vary based on the complexity of the part and the supplier’s production capacity. It’s advisable to discuss lead times with the supplier when placing an order.

Ensuring quality involves working with reputable suppliers, specifying quality standards, conducting inspections, and maintaining clear communication throughout the manufacturing process.

Yes, stainless steel parts can undergo various post-treatments and finishes, including passivation, plating, polishing, and heat treatment, depending on the desired properties and appearance.

Factors to consider include material selection, tolerance requirements, surface finish, part geometry, and the capabilities of the machining process. Collaboration with a skilled design engineer is beneficial.

Free Sample

Explore Other Products

Sheet Metal Fabrication

New Energy Battery Casing and other differentSheet Metal Fabrication parts such as Housing, Case,Enclosure, etc.

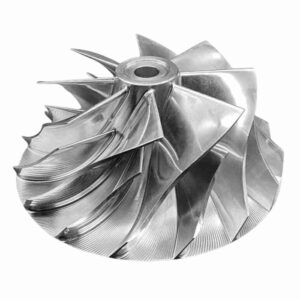

Aluminum Boat Impeller

Five-axis simultaneous complex parts machining, aluminum boat impeller, watercraft impeller, compressor impeller, turbocharger impeller,and another different 5-axis CNC parts etc.

Swiss CNC Machining

Custom Swiss CNC turningTC4 titanium alloy Anodizingmedical dental nail bone nail.