Stereo lithography Apparatus

Stereo lithography Apparatus

Stereo lithography Apparatus (SLA), also known as solid imaging or stereolithography, was introduced in 1984 as the world’s first high-speed prototyping device utilizing photopolymerization. It remains one of the most mature and widely used rapid prototyping processes. SLA technology, commonly referred to as resin 3D printing, is primarily employed for the fabrication of various molds and models. By incorporating additional components into the raw materials, it can also be utilized as an alternative to precision cast wax molds in SLA prototype molding.

Resin 3D printing enhances molding speed and accuracy. However, inevitable shrinkage during the curing of photosensitive resin leads to stress and deformation. Therefore, the developmental trend focuses on the creation of photosensitive materials with low shrinkage, rapid curing, and high strength.

SLA Technology Schematic

Working Principle:

According to the scanning path designed by the CNC-controlled scanner, a laser beam is directed onto the surface of liquid photosensitive resin, solidifying a specific area of the surface in each layer (after the resin is exposed to the laser beam). Once the resin becomes solid, the production platform is lowered by a certain distance (0.05-0.025mm). Subsequently, another layer of liquid resin is applied over the cured layer, and this process is repeated in a back-and-forth motion until the final model is completed.

Pros and Cons

Advantages

- Suitable for parts with complex structures and unique geometries, ideal for small-batch/customized production.

- Short processing cycles, smooth surfaces, clear details, and low costs.

- Optimized structures and open-minded thinking.

Disadvantages

- Resin 3D printing has low strength and is highly sensitive to temperature.

- Processing requires additional support and post-processing.

- Available materials are temporarily limited by industry applications.

Optional Materials

White Resin

- Properties: Low strength, low heat resistance, light yellow appearance

- Typical Applications: External display parts, casings.

Transparent Resin

- Properties: Low strength, low heat resistance

- Typical Applications: External display parts, casings.

Black Resin

- Properties: High strength, low heat resistance

- Typical Applications: External display parts, casings.

Yellow Resin

- Properties: High toughness, low heat resistance

- Typical Applications: External display parts, casings.

- Suitable for industries requiring precision and complex structures, such as aerospace, medical, molds, 3D printing surgical guides, etc.

Application Scope

- Validation of R&D design for appearance or functional testing.

- Small-batch customization/personalization.

- Suitable for industries requiring precise and intricate mechanisms, such as aerospace, healthcare, and molds.

Explore Other Products

Swiss CNC Machining

Custom Swiss CNC turningTC4 titanium alloy Anodizingmedical dental nail bone nail.

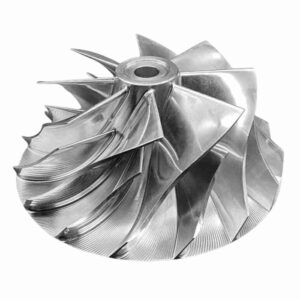

Aluminum Boat Impeller

Five-axis simultaneous complex parts machining, aluminum boat impeller, watercraft impeller, compressor impeller, turbocharger impeller,and another different 5-axis CNC parts etc.

Automatic Lathe

Test Pin and other Automatic Lathing Machining Parts such as screws,copper pillar, knob, etc.