Precision Machining Services

Precision Machining Services

Precision Machining Services–Ultra Precision Machining Manufacturer

What We Do

SurfaceMechanical Attrition Treatment(SMAT)(surface grinding)

To achieve a fine and smooth surface treatment and precise control of flat metal or non-metal objects’ flatness, dimensional accuracy, and surface finish, we utilize specialized surface grinding tools. By using a surface grinding machine to grind the surfaces, we ensure their flatness and smoothness. Typically, we maintain dimensional control within an extremely fine range, meeting precision requirements of 0.001mm. Furthermore, through surface grinding, we can achieve surface roughness levels of Ra 0.08 to 0.25μm, ensuring a high degree of surface smoothness for the components.

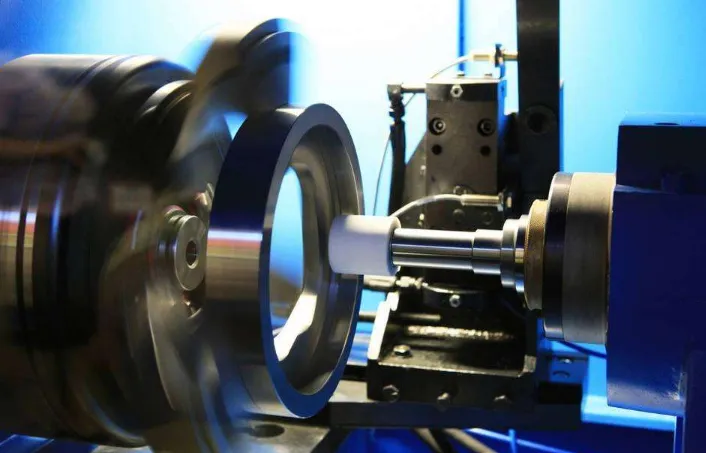

External Grinding

External cylindrical grinding is a machining process primarily performed on an external cylindrical grinding machine, used to grind the outer cylindrical, conical, and shoulder surfaces of shaft-type workpieces. During the grinding process, the workpiece rotates at a low speed while simultaneously undergoing longitudinal reciprocating motion. After each single or double stroke, the grinding wheel moves laterally in relation to the workpiece, which is known as longitudinal grinding method. In external cylindrical grinding, the workpiece is held in the grinding machine chuck, and the grinding wheel rotates and gradually approaches the workpiece to remove excess metal material, achieving the desired surface smoothness and precision.

External cylindrical grinding is commonly used for grinding workpieces that are too long or heavy to be turned. However, it is also employed for precise and accurate surface finishing on cylindrical components such as shafts, axles, and gears, ensuring the required surface smoothness and accuracy.

Internal Grinding

Diamond Turning

Why choose us

Rich Experience

Currently, Masion has three grinding machine and has many years of experience in product processing.

Quality Service

Timely communication with customers regarding production progress, 3+1 service (three services plus one backup), and on-time delivery. Customer satisfaction is the standard for evaluating product quality.

Quality Control

Masion has dedicated inspection team to ensure product quality and on-time delivery, with a measurement laboratory equipped with high-precision inspection instruments such as CMMs, optical project meter and scanners. 100% of the products undergo thorough inspection before shipment, ensuring quality assurance.

High product yield rate

With a 10-step quality inspection process and strict control at each stage, the product yield rate reaches 99%.

Precision Machining

The precision of ultra-precision machining can reach up to ±0.005mm, with surface roughness ranging from Ra 0.08 to 0.25μm.

Strong Technology

Adhering to Taiwan’s CNC machining and mature experience, strictly following precision manufacturing and processing techniques.

Fast Delivery

With three grinding machine equipment, we can meet customers’ high precision requirements and deliver products quickly.

Production Capacity

With 15 years of grinding machine experience and thousands of processed product cases, we have a team of professional grinding machine operators.

Free Sample

Explore Other Services

Sheet Metal Fabrication Service

Sheet Metal Fabrication Service – Professional Sheet Metal Fabrication Manufacturer & Supplier. Sheet Metal Fabrication Service We are a manufacturer, supplier, producer, provider, factory, and exporter specializing in professional Sheet

Rapid Prototyping Manufacturing Services

China Rapid Prototyping Manufacturing Services-Your Trusted CNC and 3D Rapid Prototyping Manufacturer. I understand that you are looking for a suitable manufacturer for rapid prototyping (3D printing, rapid CNC machining,

CNC Swiss machining

Specialized in CNC Swiss Machining Services –Leading CNC Swiss machining Companies/Manufacturers in China. What is CNC Swiss Machining? CNC Swiss machining is an advanced and rapid CNC machining technique. The