Sheet Metal Fabrication Service

Sheet Metal Fabrication Service

Sheet Metal Fabrication Service – Professional Sheet Metal Fabrication Manufacturer & Supplier.

Sheet Metal Fabrication Service

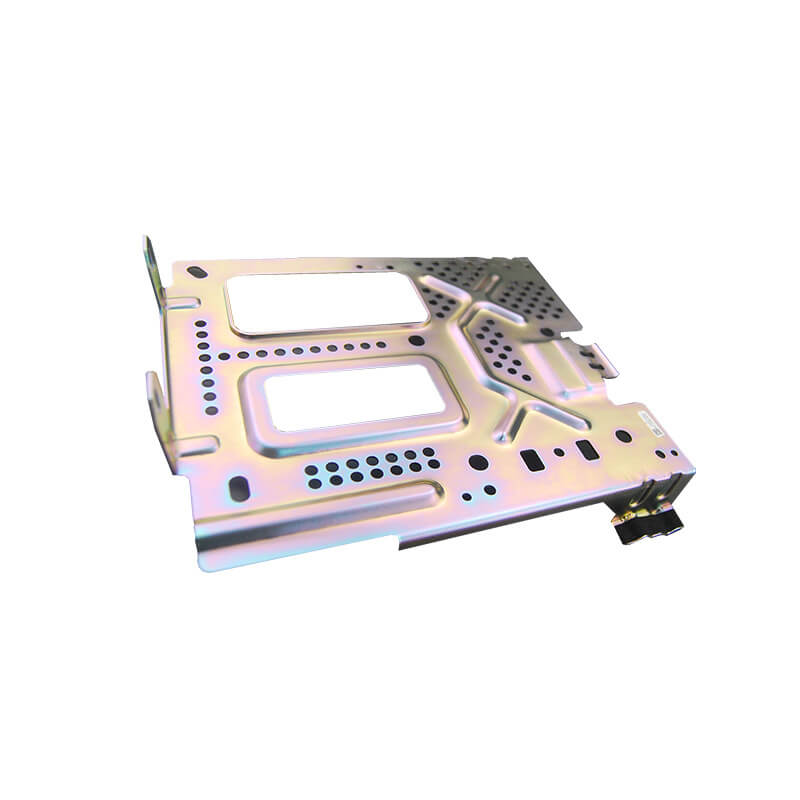

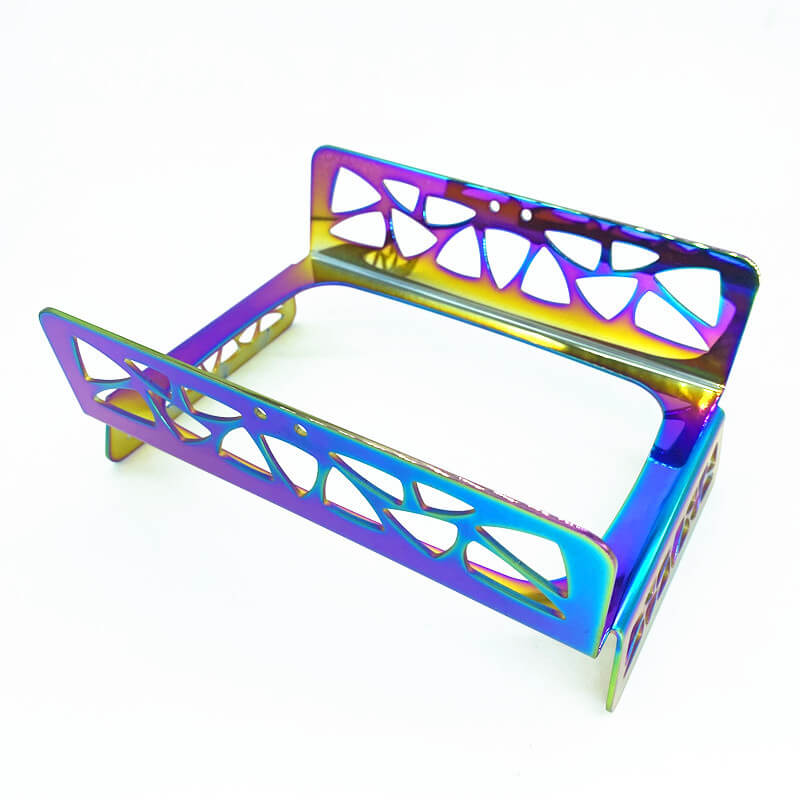

We are a manufacturer, supplier, producer, provider, factory, and exporter specializing in professional Sheet Metal Fabrication services, committed to producing a variety of sheet metal enclosures to reduce the processing cost of Sheet Metal Fabrication. We have advanced CNC punch press, laser cutting machines, and bending machines, and our main processed products include new energy battery casings, charging pile casings, portable charging cabinet casings, electrical cabinet casings, express cabinet casings, wardrobe casings, bookcase casings, low-voltage distribution cabinet casings, attendance machine casings, advertising box casings, car-mounted steam car wash casings, computer case casings, and other sheet metal parts. Maison provides high-quality Sheet Metal Fabrication services in China, offering you more competitive prices and faster delivery cycles. We have high-precision

What we do

5 axis CNC machining of aerospace parts

Sheet Metal Fabrication other parts

Why choose Masion

Rich Experience

Masion currently has extensive machining and production experience in industries such as new energy, electronics, and auto parts.

Quality Control

Masion has Professional welders to ensure product qualification rate, automatic punching equipment guarantees product accuracy, and a specialized inspection team ensures product quality. All products undergo 100% full inspection before shipment, providing quality assurance.

Precision Machining

Sheet metal parts can achieve an accuracy of ±0.1mm. The standard for bending angle tolerance is ±1°, bending opening size tolerance is ±0.3mm, and bending opening hole distance tolerance is ±0.1mm.

Fast Delivery

Multiple advanced CNC bending machines, CNC punching machines, and laser cutting machines ensure fast sample delivery and guaranteed delivery times for large orders.

Cost Reduction

With years of processing and production experience, we continuously optimize and control costs. The cost of bulk materials can be reduced through long-term cooperation with material suppliers.

Production Strength

With advanced CNC Punching Machine, Laser cutting machine and over 15 years of experience in Sheet Metal Fabrication and tens of thousands of product cases machining experience, Masion has a team of experienced designers, mechanics, engineers, etc.

How do we guarantee quality?

Man

The Sheet Metal Fabrication is equipped with excellent production and management talents, including experienced welders, machinists, and process engineers skilled operators with more than 10 years of experience, and a production manager who is a former engineer from a Taiwanese company. They have extensive experience and strict management, with a goal of delivering high-quality products on time.

Machine

High-speed and high-efficiency laser cutting machines, CNC punching machines, bending machines, and automatic punching machines, with ±0.1 size accuracy to improve product production speed and ensure product size tolerance.

Environment

Clean and tidy processing workshop further ensures the accuracy of Sheet Metal Fabrication.

Material

Incoming material inspection, no mixing of materials, to ensure the physical properties of customized sheet metal parts. By testing the size and material composition report of the material during the raw material incoming process, the authenticity of the material can be quickly identified.

Method

By strictly implementing the ISO9001:2015 quality management system, every sheet metal part is guaranteed to be qualified. Three-coordinate finished product inspection and two-dimensional inspection are performed to meet the quality requirements for delivery.

What materials of Sheet Metal Fabrication are there

| Picture | Material | Brief Introduction | Material Trademark | Surface Finish | More |

|---|---|---|---|---|---|

| Aluminum Alloy | Aluminum alloy: low density, high strength, ductility, corrosion resistance, easy to strengthen and treat, good conductivity, recyclable, and cost-effective. | AL5052-T651, AL6061-T651, AL 7075-T651, AL6082-T651 etc | A. Polishing, B. Grinding, C. Radium carving, D. Bead Blasting, E. Painting, F. Coat Plating, G. Anodizing, H. Teflon Coating, I. Laser marking, J. Silk printing, K. Silk transfer printing | Learn more |

| Brass | Brass is an alloy composed of copper and zinc. High strength, good ductility, excellent mechanical properties, high wear resistance, good corrosion resistance, and lower price. | H58 H59、H62、HA177-2、HMn58-2、HPb59-1、HSn62-1 | A. Polishing, B. Grinding, C. Laser marking, D. Screen printing, E. Transfer. | Learn more |

| Copper | High copper content, ranging from 99.5% to 99.95%. High density, melting point, excellent electrical conductivity, thermal conductivity, ductility, and corrosion resistance. | T1、T2、T3、TU1、TU2b | A. Polishing, B. Grinding, C. Brushing, D. Laser marking, E. Screen printing, F. Transfer. | Learn more |

| Stainless Steel | Low chromium content, 10.5%, high carbon content, 1.2%. High hardness, wear resistance, and high corrosion resistance. | 201、303、304、316、410、420 etc | A. Polishing, B. Painting, C. Laser marking, D. screen printing, E. transfer printing. | Learn more |

| Carbon Steel | Carbon steel, with carbon content below 0.8%, exhibits high mechanical properties, excellent processing performance, and is categorized into low, medium, and high carbon steel.. | Q175、Q215、Q235、Q275 , Q345 etc | A. Polishing, B. Grinding, C. Brushing, D. bead blasting, E. Laser marking, F. Screen printing, G. Transfer printing. | Learn more |

What is the Surface Finish of Sheet Metal Fabrication Parts?

| Picture | Process | Brief introduction | Material | Colors | Appearance | More |

|---|---|---|---|---|---|---|

| Electroplating(zinc plating) | Electroplating applies a thin metal layer onto a metal surface to prevent oxidation, improve properties, and enhance appearance. Common processes include chromium, nickel, gold, silver, and tin plating. | Copper, cast iron, steel and stainless steel, aluminum, ABS plastics, polypropylene, polysulfone, and phenolic plastics, etc. | Red, yellow, gold, green, blue, purple, rose gold, titanium, white, black, etc. | Glossy or Matte | Learn more |

| Polishing | Polishing reduces surface roughness, achieving a smooth and bright finish by mechanical, chemical, or electrochemical action. It removes imperfections and enhances paint appearance. | Copper, cast iron, steel and stainless steel, aluminum, magnesium alloy, titanium alloy, etc. | N/A | Glossy | Learn more |

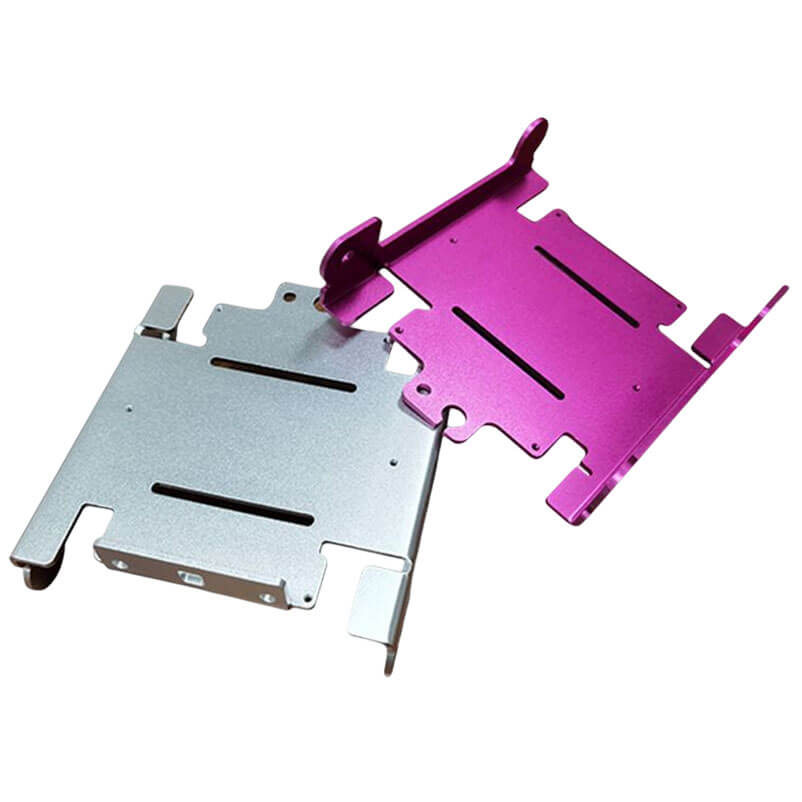

| Anodizing | Anodizing is an electrochemical process that forms an oxide film on metals, improving corrosion resistance, wear resistance, hardness, and aesthetics. | Aluminum alloy, magnesium alloy, titanium alloy, etc., | Clear, black, grey, red, blue, gold,yellow, violet, double colors, camouflage color, etc. | Matte, Semi-glossy, glossy | Learn more |

| Bead Blasting | Compressed air propels abrasive materials at high velocities to remove rust, stains, and paint, achieving a renovated appearance by grinding down burrs and scars. | Cast iron, steel, stainless steel, aluminum alloy, magnesium alloy, titanium alloy, ABS, etc. | N/A | Matte | Learn more |

| Powder Coating | Plastic spraying electrostatically applies powder coating onto metal surfaces, forming a protective, aesthetically pleasing film that resists corrosion, rust, and wear. | Cast iron, steel, aluminum alloy, magnesium alloy, ABS, and various plastics, etc. | Black, white, blue, green, yellow, purple, all the colors on the Pantone color card | Matte or glossy | Learn more |

| PVD(Physical Vapour Deposition) | PVD vaporizes material into gaseous atoms, depositing functional films on substrates. It enhances appearance, hardness, wear resistance, and corrosion resistance. | Iron, stainless steel, aluminum alloy, titanium alloy, copper, ceramics, tungsten steel, zinc alloy, ABS, and various plastics | Gold, gun black, coffee, purple, heptagon, royal blue, azure blue, black, titanium gray, so why bowl, rose gold, gold, champagne gold, etc. | Glossy | Learn more |

| Paint spraying | Spraying is a coating method using a spray gun to apply a water and oil resistant coating quickly on various surfaces. | Cast iron, steel, aluminum alloy, magnesium alloy, ABS, various plastics, etc. | Any colors demand. | Matte or glossy | Learn more |

Free Sample

Explore Other Services

Precision Machining Services

Precision Machining Services–Ultra Precision Machining Manufacturer If your product requires a very high level of dimensional tolerance that cannot be achieved through CNC machining alone, the best solution would be

Wire Edm Machining

What is EDM Machining – Electrical Discharge Machining Definition https://cncmasion.com/wp-content/uploads/2023/11/390137809503.mp4 Electrical discharge machining or EDM, also known as spark machining or spark eroding, is a metal fabrication process and non-traditional

CNC Turning Services

https://youtu.be/TfLpTK81Lw0 As a professional CNC turning manufacturer, supplier, and factory, Masionis dedicated to delivering high-precision CNC turning parts with a strong focus on cost-effectiveness. With our advanced CNC lathes, we