Electrophoretic Coating

Electrophoretic Coating

Electrophoretic Coating Process Introduction

Electrocoating is a painting method that utilizes an applied electric field to cause the directed migration and deposition of pigment and resin particles suspended in an electrocoating solution onto the surface of an electrode, typically a substrate. It is a chemical process that applies a layer of colored paint film to the workpiece.Black spot electrophoretic coating is the most widely used electrophoretic color and can be divided into high gloss, matte, and semi-matte finishes.

Common Substrates Used in Electrophoretic Coating Processing:

Almost all conductive materials (not just metal materials) can be used as substrates for electrophoretic processing! Substrates that I have personally processed through electrophoresis include steel parts (A3 steel, 45 steel, 304 stainless steel, 316 stainless steel, etc.), copper parts (brass, bronze, tin bronze, phosphor bronze, etc.), aluminum parts (aluminum alloy 2A12, aluminum alloy 6061, aluminum alloy 6063, aluminum alloy 6082, aluminum alloy 7075, etc.), iron parts, zinc alloy, etc.;

Note 1

Not all electrophoresis factories can process all materials. I have encountered many electrophoresis factories that do not process iron parts and zinc alloy parts, especially cast iron parts, because impurities in these materials may contaminate the electrophoretic solution, leading to many electrophoresis factories not processing these materials.

Electrophoretic CoatingProcessing Film Thickness, Hardness, and Neutral Salt Spray Test Duration

For products with high corrosion resistance requirements, such as automotive parts, a film thickness of 20μm or more is generally used.

For ordinary hardware processing, a film thickness of about 15μm is generally sufficient, and this is also the most widely used electrophoretic paint film thickness.

In general, the film thickness of hardware components typically only needs to be 10μm, such as for the guide rails of stamped, bent, or deformed parts.Products with precision assembly requirements are often the same, otherwise, if it is too thick, it will affect the assembly.

For some special products, such as seat springs, which do not require high corrosion resistance but have a large production volume, it can be a headache to use the conventional single-piece hanging electrophoresis method. Efficiency and benefits are extremely low. In this case, for mass-produced components, the thickness requirements for the electrophoretic film are not stringent and only require a thickness of 5-10μm.

Thin-film electrophoretic paint with a thickness of only 5μm can provide good coverage for the substrate, which effectively guarantees the increase of user productivity and cost control, creating more value!

The hardness of electrophoretic coating

Characteristics and Effects of Electrophoretic Coating

Detailed characteristics:

Electrophoretic coating can form a complete protective film even in highly concealed areas such as flanges, box structures, and tubular structures, resulting in high corrosion resistance.

Compared to spray painting, electrophoretic coating achieves a utilization rate of over 95%, reducing paint waste.

The electrophoretic process is stable and ensures a uniform coating on the workpiece.

The use of water as a carrier eliminates the risk of fire. It significantly reduces water and air pollution and reduces environmental equipment costs.

The bath solution has low viscosity (approximately equal to that of water), making it easy to pump and facilitating the draining of the coated body.

Uncured paint films are non-sticky and can even undergo certain treatments. Unlike sprayed coatings, electrophoretically deposited coatings do not run during drying.

Unlike immersion coatings, electrophoretic coatings deposited on internal surfaces are not washed off by hot steam during drying.

Due to fully automated production processes, labor costs are reduced, and coating production efficiency is greatly improved, making it highly suitable for mass production.

Electrophoretic Coating Colors

Note 1

Due to technological limitations, not all electrophoretic coating factories can produce all colors. Generally, these factories produce some standard colors. However, if a custom color is needed, a significant order volume is required to support it; otherwise, the factory will not support custom colors.

Note 2

The most common electrophoretic color we see is black, which can be produced by almost every electrophoretic factory. The difference lies in the formulation ratio, resulting in slight color variations. Black colors typically include matte black, semi-matte black, glossy black, and others.

Note 3

If your order quantity is large enough and there is enough output value, the electrophoretic factory can also cooperate with you to achieve any color you want by adjusting the color.

Electrophoretic Process Flow

Note 1

Different colors of electrophoretic coatings are achieved by adding different color pastes to the ED coating during the ED process.

Note 2

The ED (electrophoresis) process can be divided into four processes

electrolysis (decomposition), electrophoretic motion (swimming, migration), electrodeposition (precipitation), and electroosmosis (dehydration). These processes cause the charged coating ions to move to the cathode under the action of voltage and form insoluble substances on the cathode surface due to alkaline effects, which are deposited on the surface of the workpiece. By controlling the construction voltage and time and adjusting the bath temperature, the best electrophoresis effect can be achieved in combination with the proportion of various electrophoretic coatings.

Dacromet Processing Fee Explanation

Electrophoretic Processing Fee Description

Minimum Charge

A sample fee is generally charged for electrophoretic coating samples, which is also the minimum charge, usually around $40 (charges may vary from each electrophoretic factory).

Charge by piece

this mainly depends on the size of the workpiece and specific process requirements, ranging from a few cents to several dollars or tens of dollars per piece.

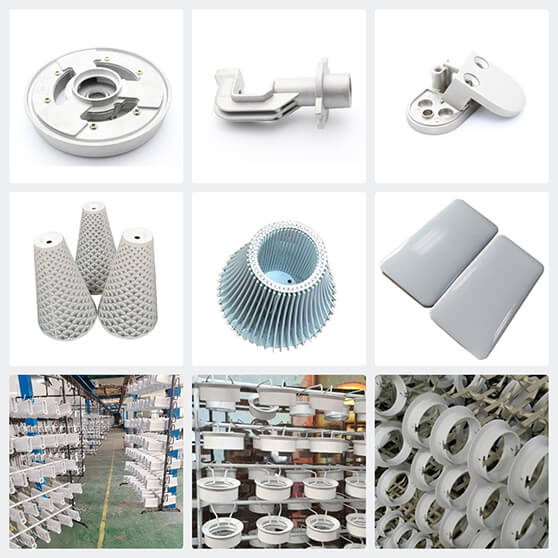

Electrophoretic Processing Production Equipment Display

Power Supply:

The power supply provides the electric current that is used to deposit the coating material onto the product. The voltage and amperage of the power supply are carefully controlled to ensure consistent coating thickness and quality.

Anodes and Cathodes

Anodes and cathodes are used to generate the electric field that is used to deposit the coating material onto the product. The anodes are typically made of lead or graphite, while the cathodes are made of stainless steel or other materials.

Heat Exchanger

A heat exchanger is used to regulate the temperature of the electrocoating solution. The temperature must be carefully controlled to ensure consistent coating quality and thickness.

Filtration System

The electrocoating solution must be filtered to remove any impurities that may affect the quality of the coating. The filtration system is a filtering device used in the pre-treatment stage to separate the resin in the paint from water, solvents, and dissolved metal impurities. The ultrafiltration process is a separation process between the continuous phase (water + solution + dissolved impurities including dye salts) and the dispersed phase (resin and pigments). It can also be referred to as the separation process between the aqueous phase and the organic phase. The aqueous phase, which passes through the ultrafiltration membrane, is called the "permeate." The permeate contains solvents, all water-soluble ionic impurities, and some low molecular weight resins.

Conveyor System

A conveyor system is used to transport the product through the electrocoating tank. The speed and orientation of the conveyor system are carefully controlled to ensure even coating thickness.

Drying Oven

After the product has been coated, it must be dried to remove any excess moisture from the coating. A drying oven is used to heat the product and evaporate any remaining solvent.

Electrophoretic Processing and Testing Equipment Display

Appearance inspection

After electrophoresis, the surface should be free of particles, lumps, pits, shrinkage holes, pinholes, water droplet marks, stains, foreign materials, hanging flow, unevenness, roughness, exposure, peeling, and other defects; detection method: naked eye observation;

Film thickness detection

Check whether the thickness of the electrophoretic paint layer meets the predetermined requirements; detection method: film thickness gauge;

Adhesion test of electrophoretic paint layer

(1) Scratch grid method: that is, conduct a scratch test with 100 grids at a 1mm distance, with the scratch depth reaching the base material, then stick with 3M tape and instantly pull it off with force, and it should not fall off more than 20/100; (2) Scratch test with circular rolling line: measure with an adhesion tester, not lower than level 5 in GB/T1720.

Hardness of electrophoretic paint layer

Measured by plowing method: use a 2H pencil to cut the tip, push the pencil at a 45-degree angle against the test material, and there should be no scratches on the surface.

Neutral salt spray test (NSS)

The electrophoretic parts require a neutral experiment of 24 hours or 48 hours. After the experiment, there should be no white, black, or brown corrosion points on the edges and outer surfaces of the samples, and the coverage layer should not be lower than level 5 according to GB/T6461.

Electrophoretic Processing Sample Case

Here are some examples of electrophoretic coating samples:

Automotive components

Electrophoretic coating can provide corrosion-resistant and wear-resistant protection for automotive components, such as wheels, grilles, and door handles.

Furniture accessories

Electrophoretic coating can provide a variety of colors and gloss for furniture accessories, while improving their corrosion resistance and durability, such as door handles, hardware fittings, and metal legs.

Electronic products:

Electrophoretic coating can provide an aesthetically pleasing protective layer for electronic products, while improving their corrosion resistance and electrical insulation properties, such as electronic shells, chassis, and panels.

Building decoration

Electrophoretic coating can provide a variety of colors and texture effects for building decoration materials, while improving their corrosion resistance and durability, such as aluminum alloy doors and windows, curtain walls, and aluminum plates.

Other applications

Electrophoretic coating can also be used in other applications, such as mechanical components, pipelines, instruments and meters, and ship equipment.

Free Sample

Explore Other Surface Finish

Mirror Polishing

Mirror polishing is a machining method that uses mechanical, chemical, or electrochemical actions to reduce the surface roughness of the workpiece and obtain a bright and smooth surface. It is

Anodizing

Aluminum Anodized Finish (Aluminum Anodizing) Brief introduction to the aluminum anodizing process Anodic oxidation, also known as aluminum anodizing, refers to the electrochemical oxidation of metals or alloys. It is

Bright Tin Plating

Bead Blasting, also known as abrasive blasting or sandblasting,typically involves the use of compressed air to propel abrasive particles from a nozzle and direct them onto the surface to be