PVD Coating

Rose gold PVD plating.

304 stainless steel part (3D printed) with copper-nickel-chromium electroplating base coat and rose gold PVD plating.

304 stainless steel part (3D printed) with copper-nickel-chromium electroplating base coat and rose gold PVD plating.

Plating: Copper-nickel-chromium electroplating, rose gold vacuum plating

Process: Rack plating

Color: Rose gold

Reference price: $0.5 per piece

Difficulties in electroplating this part

Titanium PVD Gold

Yellow Brass Jewelry Components Water Plating

Base Material: Brass H62

Plating: Copper-Nickel-Chromium Undercoat followed by PVD Vacuum Titanium Gold Coating

Process: Hanging Plating

Additional Process: Mechanical Mirror Polishing

Color: Titanium Gold

Film Thickness: 15μm on one side

Electroplating Price: 0.6 USD/piece

What are the advantages of PVD Vacuum Coating?

Uniform and consistent color

Durable surface that maintains a good appearance in various air and direct sunlight conditions

Deep and bright colors

Economical, reducing the time and cost required for cleaning and polishing compared to electroplating brass or gold

Environmentally friendly, avoiding chemical toxicity

Biocompatible

Coating Characteristics:

Resistance of PVD Coatings:

Vacuum Deposition

Introduction to Vacuum Electroplating(PVD) Process

Characteristics of the PVD vacuum electroplating process

Vacuum coating, PVD electroplating, and characteristics of vacuum coating

Characteristics of PVD vacuum coating layer

Resistance of PVD coating

Environmentally friendly process

Vacuum Electroplating(PVD) Process

On the automatic line

Automatic electrostatic dust removal

Automatic surface primer spraying

Infrared (IR) drying

UV surface curing

Down the automatic line

Non-conductive equipment control system

Non-conductive vacuum coating in progress

Non-conductive coating unloading

Automatic spray painting and coloring

Downstream fixture

Vacuum Electroplating(PVD) Equipment Showcase for Production

Vacuum Electroplating(PVD) Inspection Equipment Showcase

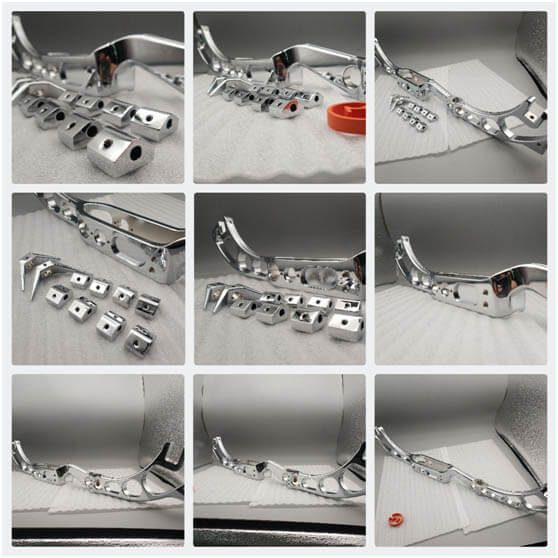

Vacuum Electroplating (PVD) Sample Case

Free Sample

Explore Other Surface Finish

Chrome Plating

Bead Blasting, also known as abrasive blasting or sandblasting,typically involves the use of compressed air to propel abrasive particles from a nozzle and direct them onto the surface to be

Metal Passivation

Passivation refers to the process of treating the metal with a strong oxidant or electrochemical method to oxidize its surface, making it passive, i.e., transforming the metal surface into a

QPQ Coating

Phosphating is a process in which a workpiece is treated in a phosphoric acid salt solution containing manganese, iron, and zinc to form a layer of insoluble phosphate film on