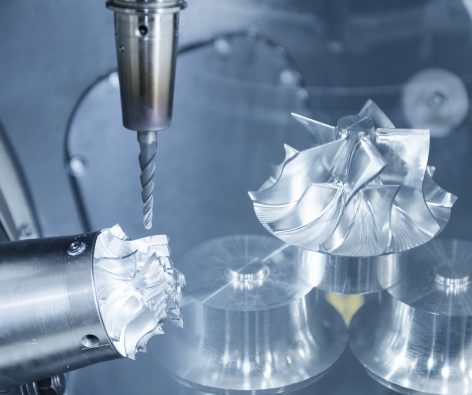

MASION, with 21 years of complex parts (billet compressor wheel) and five-axis CNC machining parts experience in China, provides one-stop customized CNC Machining services (design, raw materials procurement, CNC machining, surface treatment, CMM inspection, packaging, shipment) for engineers, product developers, designers, and other customers. All products are completed by precision, advanced CNC machine (5-axis CNC machine, Swiss Machine, and CNC milling-lathe machine). All professional and experienced teams (sales, designers, operators, and inspectors) help customers solve any problems throughout the machining process. Our fast, precise CNC machining capabilities, flexible production, and transportation can meet your demand from product development to mass production at a competitive price.

Our unique customized CNC machining services

Masion possesses skilled and professional machinists and engineers with years of practical CNC Machining experience, enabling us to quickly respond to various CNC machining methods and products while providing appropriate solutions. We can meet the growing demands for customized CNC machining services from our clients, accomplishing the manufacturing of products with aesthetic requirements and intricate shapes.

Masion specializes in professional CNC machining of complex and irregular parts using 3-axis, 4-axis, and 5-axis machines. We are equipped with CNC milling machines, CNC turning, wire cutting, EDM machines, and CNC drilling and tapping equipment. Our aim is to provide you with professional, convenient, and fast CNC machining services. Masionspecializes in the production of components for industries such as medical, electronics, automotive parts, robotics, defense, telecommunications, and shipbuilding.

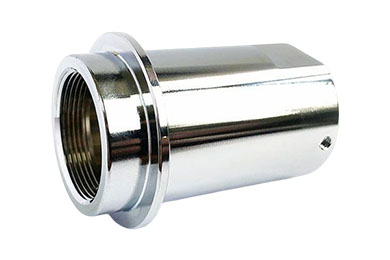

Swiss-type lathes from Masion are suitable for machining a large number of small and complex cylindrical parts, such as various shafts. These lathes have a turning diameter range of 0.045" to 1.5" (1.1 mm - 38 mm). The straightness and concentricity tolerances are also strictly maintained. Currently, Masion's Swiss-type lathes are equipped with bar feeders, enabling efficient and cost-effective production of slender and elongated shaft-type parts in large quantities.

Masion focuses on CNC end face and side milling, drilling, tapping, and other turn-milling complex machining, We are good at machining the shape of complex, high precision requirements of the special-shaped complex parts of the rotary body, a clamping to complete all or most of the process machining.We can ensure accuracy, but also improve efficiency, and reduce cost, We are specialized inprofessional medical, robot, auto parts, and other turn-milling complex machining.

Masion is one of the advanced rapid mold manufacturers, providing customers with one-stop prototyping and production solutions, offering a wide range of 3D printing services including SLA 3D printing (stereoscopic lithography), SLS 3D printing (laser sintering), MJF (Multi-fusion) and DLMS (laser melting), SLM and other technologies;

Masion provides all kinds of sheet metal parts customization, laser cutting, CNC stamping, cutting, bending edge, bending forming, welding, riveting, and other processes. Materials are cold-rolled plate (SPCC), hot-rolled plate (SHCC), galvanized plate (SECC, SGCC), copper (CU) brass, copper, beryllium copper, aluminum plate (6061, 5052, 1010, 1060, 6063, duralumin, etc.), stainless steel (mirror, wire drawing surface, fog surface)

Masion could support fine turning, fine milling, fine boring (diamond boring), fine grinding, fine honing, fine drilling, ultra-precision turning, mirror grinding, and grinding, the accuracy can reach 0.005mm. The surface roughness is Ra0.02 ~ 0.005μm.

What every customized service client’s primary concern is finding a suitable, trustworthy, secure, stable, professional, capable, and highly cooperative CNC machining supplier? This is also a pain point for every customer. Masion can assist clients in addressing these pain points, ensuring they can rest assured and have peace of mind.

Masion boasts a team of highly experienced professionals, including specialized designers and product engineers. We offer a comprehensive range of services for all products, starting from feasibility analysis and design proposals to product manufacturing process optimization and aesthetic recommendations. Our goal is to assist clients in refining their designs, reducing costs, and ensuring product quality consistency through the implementation of a rigorous quality management system and 100% inspection.Our dedicated engineering team is always on standby and fully prepared to provide prompt and excellent support to our clients. We are committed to helping your projects swiftly transition from conceptual designs to tangible products.

Maison prides itself on its cutting-edge CNC machinery, encompassing a diverse range of machining methods such as CNC Swiss Machining, CNC milling and turning machines, 3-axis, 4-axis, and 5-axis CNC machining centers, 3D printers, milling turning machines, laser cutting machine, CNC lathe, bending machine, injection molding machines, and cylindrical grinding. Our capabilities extend to meeting varied requirements for surface smoothness and precision, offering tailored service solutions for our clients. Additionally, Maison provides a spectrum of tolerance options in compliance with international standards such as ISO 2768 (Standard, Fine), ISO 286 (Grades 8, 7, 6), ANSI, GB, DIN, etc., with tolerances ranging from 0.001mm to 0.01mm.

Maison excels in communication, promptly addressing customer inquiries with precise quotations and effective solutions. In the sampling phase, we demonstrate efficiency, rapidly producing and presenting required samples to meet review and approval needs. Emphasizing delivery speed, we closely collaborate to understand customer deadlines, optimize production plans, and streamline logistics for timely delivery. Recognizing the pivotal role of on-time delivery in project success, we uphold rigorous quality standards and maintain a steadfast commitment to integrity, contributing significantly to gaining customer recognition. Our dedication to clear communication, efficient processes, and unwavering quality underscores Maison’s commitment to exceeding customer expectations.

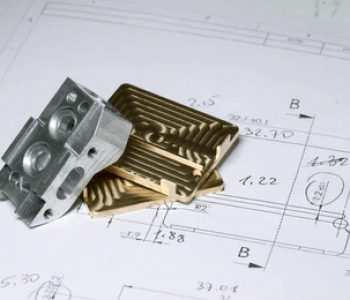

We have received your inquiry which contains.step or. Auto Cad drawing and detailed requirements of the products, we will review the dimensions, tolerances, materials, and surface treatment according to the requirements of the drawings, calculate the price, and then we will quote you the correct price. After you confirm the price, we will arrange to produce the sample and send it to you for testing.

The samples have been confirmed to meet the dimensions, tolerances, and materials specified in the drawings. Next, you can proceed to place the order, and we will commence mass production. If any issues arise during various stages of production, we will promptly communicate with you. We ensure that the delivery schedule will definitely meet your requirements.

We will use specialized testing equipment to conduct a 100% process inspection and pre-packaging inspection of the products, ensuring that all products meet the required quality standards. Once you receive the products and confirm that the quality meets the requirements, we guarantee the product quality within 30 days. Furthermore, we will continuously monitor the product quality, so you can confidently entrust the project to us.

Dacromet is a new type of anti-corrosion coating with strong anti-corrosion properties, high-temperature resistance, and non-polluting.

Masion can provide chroming services such as black chrome plating, hard chrome plating, pearl chrome plating, decorative chrome plating,etc.

Masion can provide gold-plating services including bright gold plating, rose gold plating, hard gold plating, pearl gold plating, 18k, 24k gold plating, champagne gold plating.

Masion provides powder coating with different colors with stable quality, and good color consistency.

Masion provides anodizing for different aluminum and titanium CNC machining parts, including hard anodizing, camouflage anodizing, two-color anodizing, etc.

Massion supports electroplating services such as PVD gold, titanium alloy gold plating, rainbow gold plating, rose gold plating, gun color plating, and so on.

Roller shaft,Turn-milling composite processing, 7075 aluminum machining, and another turning and milling CNC machining parts.

Stainless Steel stethoscope Chestpiece and another different CNC turning Parts.

Roller shaft,Turn-milling composite processing, 7075 aluminum machining, and another turning and milling CNC machining parts.

CNC Milling Aluminum different automobile hub, and different 3-axis, 4-axis,5 axis CNC machining parts.

Masionprovides a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering), MJF (Multi Jet Fusion), and DLMS (Direct Metal Laser Sintering).

Five-axis simultaneous complex parts machining, brass impeller, watercraft impeller, compressor impeller, turbocharger impeller,and another different 5-axis CNC parts etc.

Five-axis simultaneous complex parts machining, aluminum boat impeller, watercraft impeller, compressor impeller, turbocharger impeller,and another different 5-axis CNC parts etc.

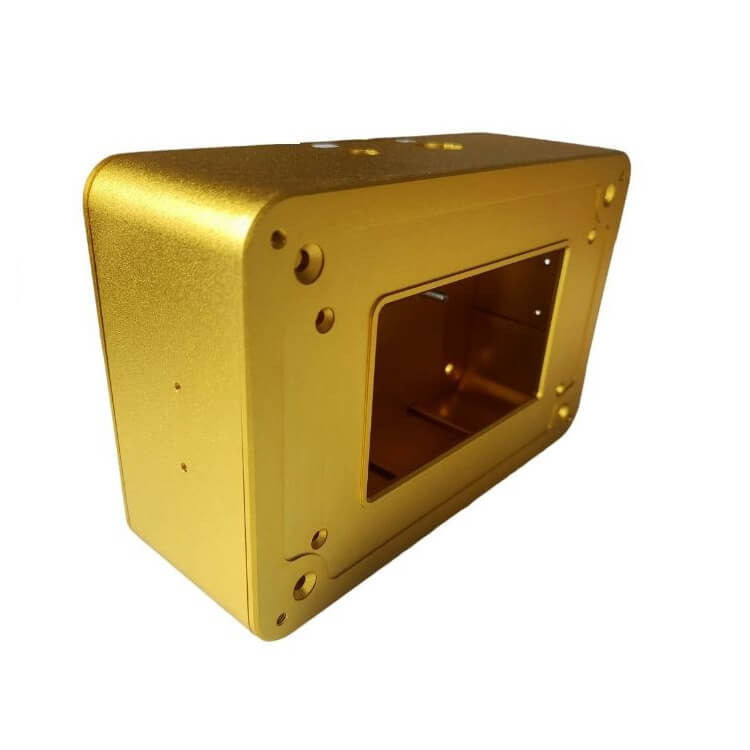

Aluminum Controller Shell and other differentSheet Metal Fabrication parts such as Housing, Case,Enclosure, etc.

CNC machining is also widely used in the military industry, including small products such as gunstock, gun handles, bullet cases, gun optical scopes, sensor components, military communication modules, and large products such as tanks, armored vehicles, and military UAV accessories. The materials generally include carbon fiber, titanium alloy, super-alloy, etc.

Semiconductor core parts can be divided into two types, namely customized precision machining parts and common outsourcing parts, such as Valves, PressureGauges,ESC electrostatic suckers, MFC flowmeters, RF power supply, and stepper motors, which have high requirements on CNC precision and reliability. Materials are mainly metal, ceramic, graphite, plastic, quartz, etc.

Now, robots have been widely used in a variety of industrial machining, so the precision requirements of the robot parts are higher and higher, CNC machining can basically meet the required standard, such as robot joints, robot arms, robot decelerators, and so on. The main material is stainless steel, titanium alloy, aluminum alloy, carbon fiber, and so on.

In CNC machining, a wide range of parts have been involved inthe medical industry, such as dental nails, teeth cleaning heads, bone nails, ultrasonic tools, bone plates, medical bone file parts, implantable medical instrument parts, surgical robot parts, surgical instrument parts, surgical robot body and so on, materials generally include stainless steel, titanium alloy, and other high-end materials.

CNC Machine is originally used to produce CNC parts, but their own partshave been also CNC machined by CNC machines, such as a variety of fixtures, tools, cutter, rotating shaft, machine housing, tool post, feed-rod, joystick (control lever), worktable, feed box, three jaw chuck, leadscrew, etc., the material generally include tool steel, iron plate, stainless steel plate, aluminum, and other metal materials.

The parts of CNC Rapid Prototype Manufacturing have been widely applied in high-tech households, such asrefrigerators, air conditioning, sweeping robot, camera, blender, iron, water dispenser, table lamp shell, and accessories.Machining materials generally include plastic, aluminum, stainless steel, copper, and so on.

The standard of food production and packaging machineryparts is getting higher and higher. Therefore, high-quality CNC machiningcould meet the higher and higher standard, The parts include the parts for sterilizer, ultrasonic cleaning machine, juicer, filling machine, dryer, roller kneading machine, desalting machine, spray cleaning machine, screen separator, silicon carbide grinding roller, sorting conveyor or crusher, pressure mill and other custom-designed CNC machining parts of food machining equipment.

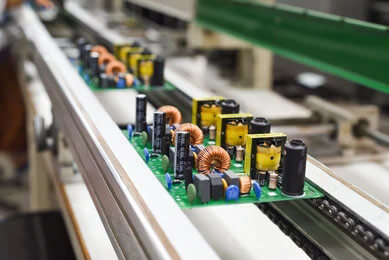

CNC machining is also widely usedin the electronics industry, such as cameras, phones, computers, speakers, headphones, smart watches, projectors and printers, TV, laptop, and even a variety of smart home accessories, shells, etc., general machining materials are aluminum, brass, copper, stainless steel, alloy steel, zinc alloy plate, plastic and so on.

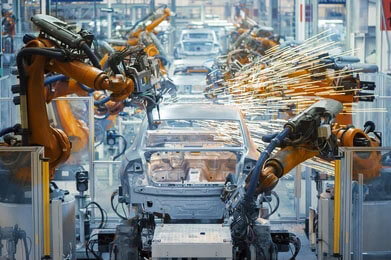

There are more CNC machiningparts in the automotive industry, such as all kinds of the rotating shaft, drive shafts, gears, gearboxes, hubs, brake drums, brake discs, engine internal parts, cylinder heads, cylinder blocks, crankshafts, valve guide rod, bushing, valve core, connecting rod, cylinder block, crankshaft, speed change system, speed change box, fork, gear chassis, etc., Generally used in die casting, casting, forging, sheet metal, CNC machining, and other processes, materials generally have aluminum, stainless steel, iron, copper and so on.

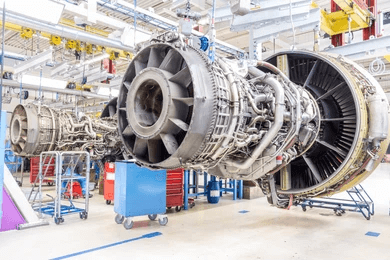

Aerospace equipment and aircraft parts require the best materials to make hinges, bushings, valves, fixtures, or other custom parts of the highest quality metal. Titanium and kovar alloys are most commonly used in aerospace components, but other components materials include stainless steel, Inconel(nickel-chromium iron alloy ), aluminum, brass, bronze, ceramics, copper, and other specific types of plastics.

There are all kinds of ships and Marine equipment accessoriesgenerally machined by CNC withhigh precisionin the Marine industry, such as crankshaft, body, cylinder head, connecting rod and camshaft, large Marine propeller, rudder blade, rudder rod, crane, anchor reaming machine, separator and other Marine products manufacturing.